Woodworker's Journal 1984-8-2, страница 25

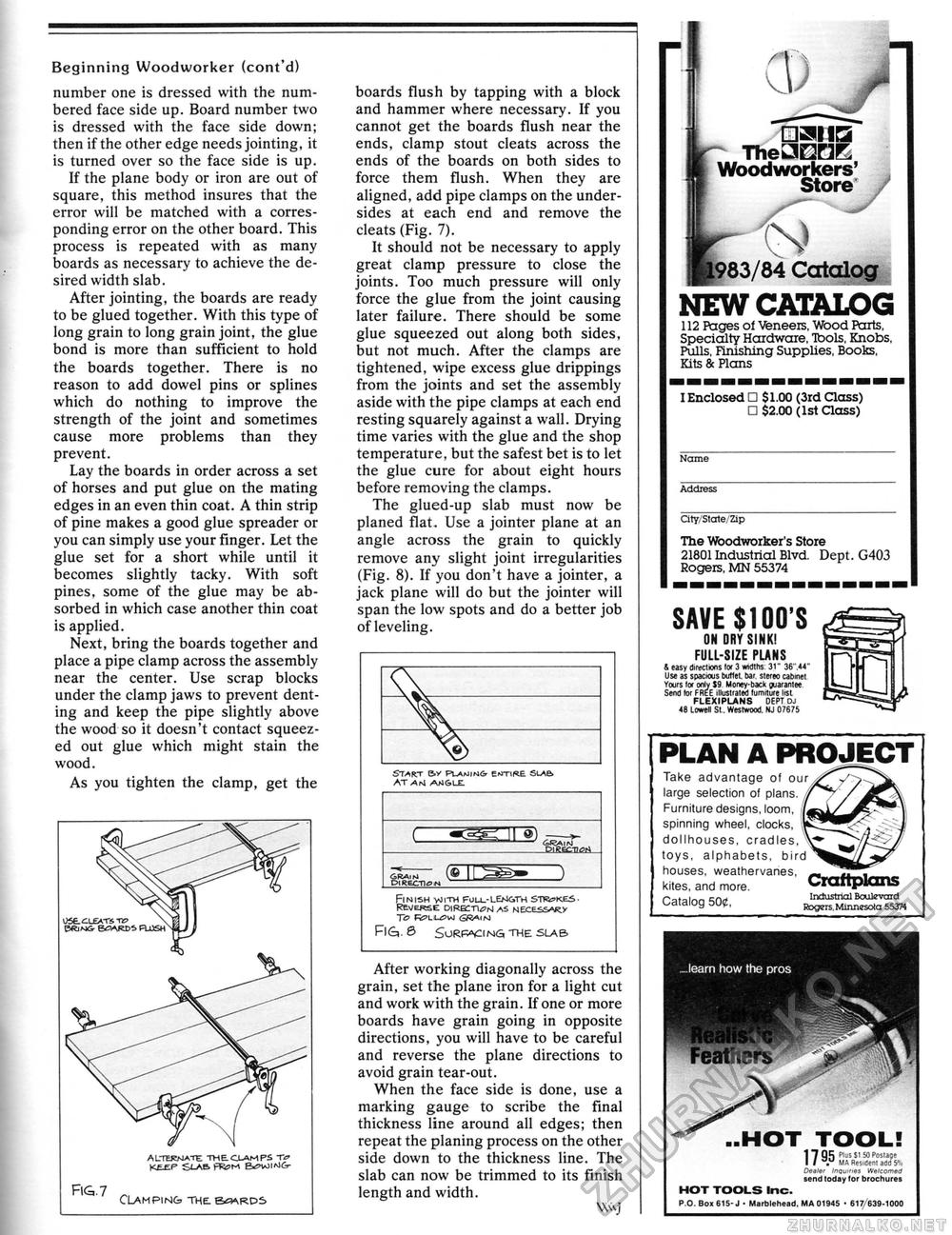

Beginning Woodworker (cont'd) number one is dressed with the numbered face side up. Board number two is dressed with the face side down; then if the other edge needs jointing, it is turned over so the face side is up. If the plane body or iron are out of square, this method insures that the error will be matched with a corresponding error on the other board. This process is repeated with as many boards as necessary to achieve the desired width slab. After jointing, the boards are ready to be glued together. With this type of long grain to long grain joint, the glue bond is more than sufficient to hold the boards together. There is no reason to add dowel pins or splines which do nothing to improve the strength of the joint and sometimes cause more problems than they prevent. Lay the boards in order across a set of horses and put glue on the mating edges in an even thin coat, A thin strip of pine makes a good glue spreader or you can simply use your finger. Let the glue set for a short while until it becomes slightly tacky. With soft pines, some of the glue may be absorbed in which case another thin coat is applied. Next, bring the boards together and place a pipe clamp across the assembly near the center. Use scrap blocks under the clamp jaws to prevent denting and keep the pipe slightly above the wood so it doesn't contact squeezed out glue which might stain the wood. As you tighten the clamp, get the FIG-7 ALTERNATE THE CLAM PS Ts> KE£P SLAS- FRSM S«?WIMCJ- CLAMPINGj THE. boards flush by tapping with a block and hammer where necessary. If you cannot get the boards flush near the ends, clamp stout cleats across the ends of the boards on both sides to force them flush. When they are aligned, add pipe clamps on the undersides at each end and remove the cleats (Fig. 7). It should not be necessary to apply great clamp pressure to close the joints. Too much pressure will only force the glue from the joint causing later failure. There should be some glue squeezed out along both sides, but not much. After the clamps are tightened, wipe excess glue drippings from the joints and set the assembly aside with the pipe clamps at each end resting squarely against a wall. Drying time varies with the glue and the shop temperature, but the safest bet is to let the glue cure for about eight hours before removing the clamps. The glued-up slab must now be planed flat. Use a jointer plane at an angle across the grain to quickly remove any slight joint irregularities (Fig. 8). If you don't have a jointer, a jack plane will do but the jointer will span the low spots and do a better job of leveling. START &V PUA<J1H&- EmRt SLAB AT ArJ Afl&LE. m saetL (g ) FINISH with FUU_-LEMC.TH STCPKE6. REVERSE direction! AS HEceiSAi^y To fiPLJjSVJ SfaAlN Fl &. 8 SuRPNCI N& THE SU & After working diagonally across the grain, set the plane iron for a light cut and work with the grain. If one or more boards have grain going in opposite directions, you will have to be careful and reverse the plane directions to avoid grain tear-out. When the face side is done, use a marking gauge to scribe the final thickness line around all edges; then repeat the planing process on the other side down to the thickness line. The slab can now be trimmed to its finish length and width. Wvj Address Clty/State/Zip The Woodworker's Store 21801 Industrial Blvd. Dept. G403 Rogers. MN 55374 SAVE $100'S ON DRY SINK! FULL-SIZE PLANS & easy directions lor 3 widths: 31" 36".44" Use as spacious buffet, bar. stereo cabinet Yours lor only J9 Money-back guarantee Send for FREE illustrated furniture list FLEXIPLANS DEPT DJ 48 Lowe! St., Westwood. WJ 07675 PLAN A PROJECT Take advantage of our targe selection of plans. Furniture designs, loom, spinning wheel, clocks, (tollhouses, cradles, toys, alphabets, bird houses, weathervanes, kites, and more. Catalog 50®, Craftplans Industrial Boulevard Rogers, Minnesota 55374 /84 Catc NEW CATALOG 112 Pages of Veneers, Wood Parts, Specialty Hardware. Tbols, Knobs, Pulls, Finishing Supplies, Books, Kits 8c Hans I Enclosed □ $1.00 (3rd Class) □ $2.00 (1st Class) ..HOT TOOL! 179.5! I Plus $150 Postage MA Resident add 5% De»ler inquiries Welcomed send today for brochures HOT TOOLS Inc. P.O. Box 615-J - Marbtehead. MA 01945 • 617/639-1000 |