Woodworker's Journal 1984-8-5, страница 7

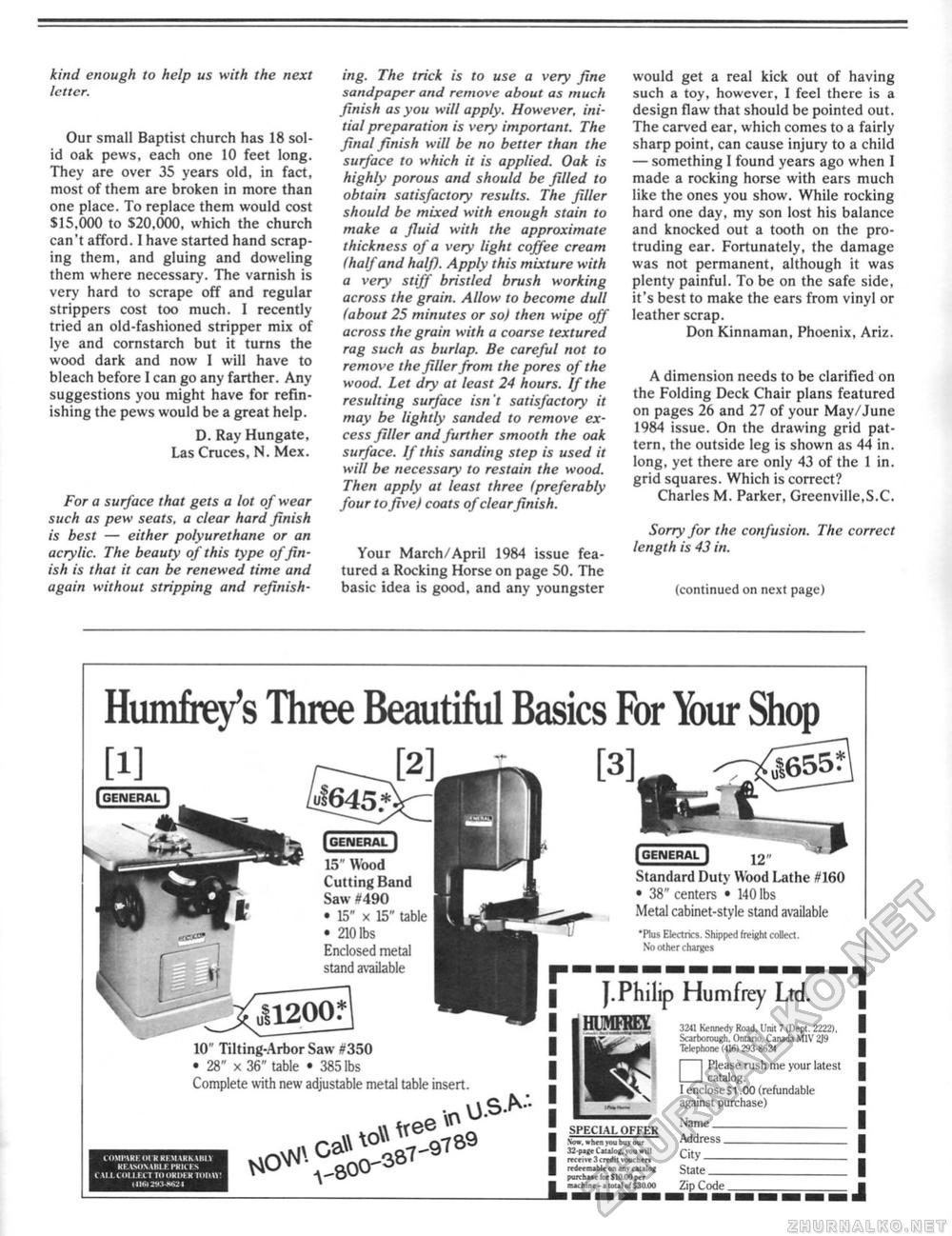

kind enough to help us with the next letter. Our small Baptist church has 18 solid oak pews, each one 10 feet long. They are over 35 years old, in fact, most of them are broken in more than one place. To replace them would cost $15,000 to $20,000, which the church can't afford. I have started hand scraping them, and gluing and doweling them where necessary. The varnish is very hard to scrape off and regular strippers cost too much. I recently tried an old-fashioned stripper mix of lye and cornstarch but it turns the wood dark and now 1 will have to bleach before 1 can go any farther. Any suggestions you might have for refin-ishing the pews would be a great help. D. Ray Hungate, Las Cruces, N. Mex. For a surface that gets a lot of wear such as pew seats, a clear hard finish is best — either polyurethane or an acrylic. The beauty of this type of finish is that it can be renewed time and again without stripping and refinish- ing. The trick is to use a very fine sandpaper and remove about as much finish as you will apply. However, initial preparation is very important. The final finish will be no better than the surface to which it is applied. Oak is highly porous and should be filled to obtain satisfactory results. The filler should be mixed with enough stain to make a fluid with the approximate thickness of a very light coffee cream (half and half). Apply this mixture with a very stiff bristled brush working across the grain. Allow to become dull (about 25 minutes or so) then wipe off across the grain with a coarse textured rag such as burlap. Be careful not to remove the filler from the pores of the wood. Let dry at least 24 hours. If the resulting surface isn't satisfactory it may be lightly sanded to remove excess filler and further smooth the oak surface. If this sanding step is used it will be necessary to restain the wood. Then apply at least three (preferably four to five) coats of clear finish. Your March/April 1984 issue featured a Rocking Horse on page 50. The basic idea is good, and any youngster would get a real kick out of having such a toy, however, I feel there is a design flaw that should be pointed out. The carved ear, which comes to a fairly sharp point, can cause injury to a child — something I found years ago when 1 made a rocking horse with ears much like the ones you show. While rocking hard one day, my son lost his balance and knocked out a tooth on the protruding ear. Fortunately, the damage was not permanent, although it was plenty painful. To be on the safe side, it's best to make the ears from vinyl or leather scrap. Don Kinnaman, Phoenix, Ariz. A dimension needs to be clarified on the Folding Deck Chair plans featured on pages 26 and 27 of your May/June 1984 issue. On the drawing grid pattern, the outside leg is shown as 44 in. long, yet there are only 43 of the 1 in. grid squares. Which is correct? Charles M. Parker, Greenville,S.C. Sorry for the confusion. The correct length is 43 in. (continued on next page) Humfrey's Three Beautiful Basics For Your Shop [1] [3], [general"! 15" Wood Cutting Band Saw #490 • 15" x 15" table • 210 lbs Enclosed metal stand available us1200f 10" Tilting-Arbor Saw #350 • 28" x 36" table • 385 lbs Complete with new adjustable metal table insert. O.S-* C8» ^-9789 Standard Duty Wood Lathe #160 • 38" centers • 140 lbs Metal cabinet-style stand available 'Plus Electrics. Shipped freight collect. So other charges ]. Philip Humfrey Ltd. HUMFREK SPECIAL OFFER Now, •h#n>cMjl)v* our 32-fU£F fMllag, SV.II wii: receive 3. rttl: I ttHithtr* rtdetraiM* on *ny ettalag piifv h (or 110.00 [M r hmr - a ol (30.00 3241 Kennedy Road, Unit 7 (Dept. 2222), Scarborough. Oraaro, Canada M1V 39 Telephone (416) 293-8624 □ Please rush me your latest catalog. 1 enclose S1.00 (refund able against purchase) Name_ Address_ City- State_ Zip Code___ '1 I I I I I I I I J |