Woodworker's Journal 1985-9-2, страница 16

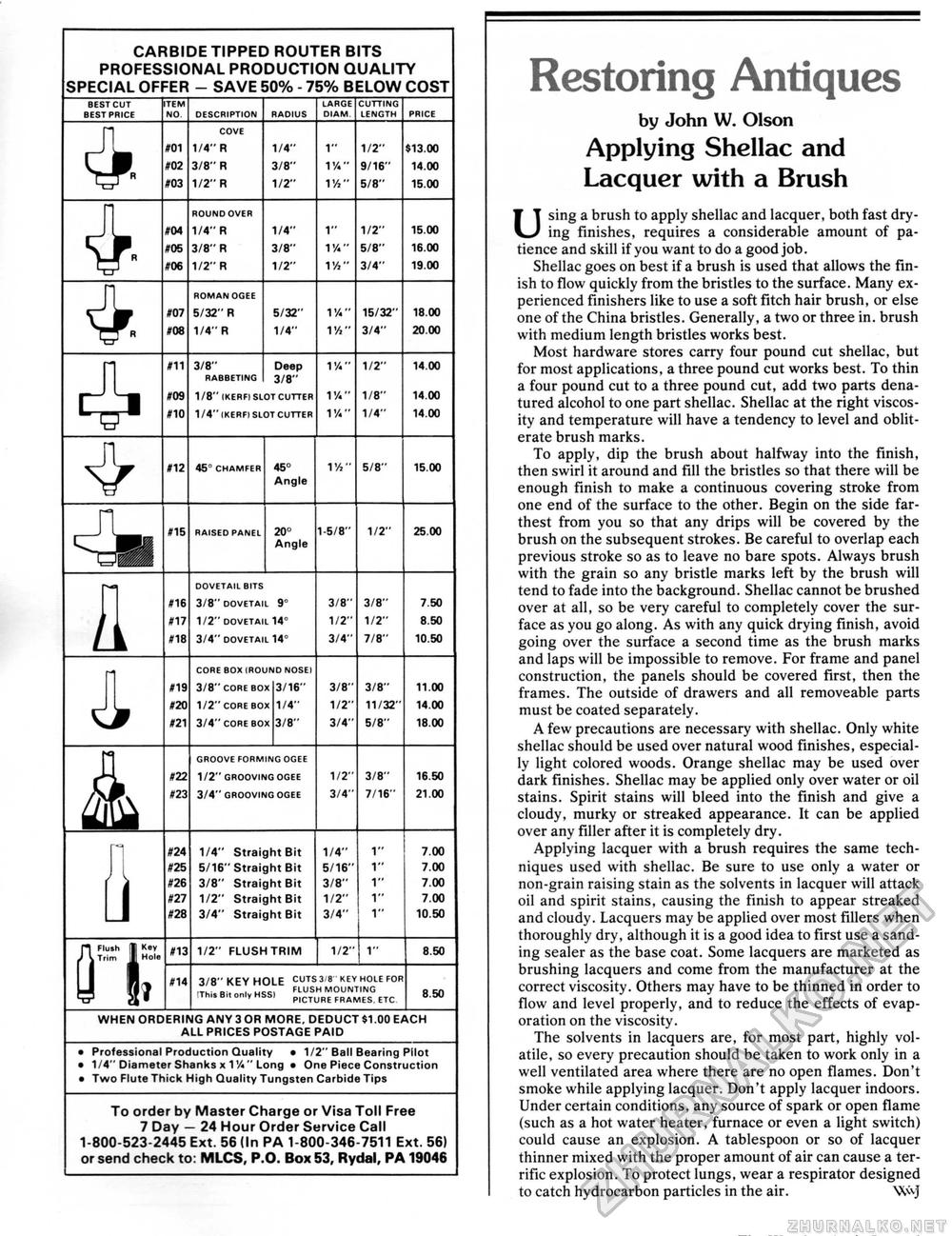

CARBIDE TIPPED ROUTER BITS PROFESSIONAL PRODUCTION QUALITY SPECIAL OFFER - SAVE 50% - 75% BELOW COST BEST CUT BEST PRICE ITEM NO DESCRIPTION LARGE DIAM. CUTTING LENGTH #01 #02 #03 COVE 1/4" R 3/8" R 1/2" R 1/4" 3/8" 1/2" 1" 1%' 1%' 1/2" 9/16" 5/8" $13.00 14.00 15.00 #04 #05 #06 ROUNOOVER 1/4" R 3/8" R 1/2" R 1/4" 3/8" 1/2" 1" 1 % " 1V4" 1/2" 5/8" 3/4" 4 #07 #08 ROMAN OGEE 5/32" R 1/4" R 5/32" 1/4" 1%" 15/32' 3/4" £ #11 #09 #10 3/8" RABBETING Deep 3/8" 1/8"|KERFI SLOT CUTTER 1/4" IKERFI SLOT CUTTER 1%' 1%' 1%' 1/2" 1/8" 1/4" #12 45" CHAMFER 45° Angle 1%' 5/8" #15 RAISED PANEL 20° Angle 1-5/8" 1/2" A #16 #17 #18 DOVETAIL BITS 3/8" DOVETAIL 9° 1/2" DOVETAIL 14° 3/4" DOVETAIL 14° 3/8" 1/2" 3/4" 3/8" 1/2" 7/8" CORE BOX IROUND NOSEI #19 #20 #21 3/8" CORE BOX 1/2" CORE BOX 3/4" CORE BOX 3/16" 1/4" 3/8" 3/8' 1/2' 3/4' 3/8" 11/32" 5/8" #22 #23 GROOVE FORMING OGEE 1/2" GROOVING OGEE 3/4" GROOVING OGEE 1/2' 3/4' 3/8" 7/16" h #24 #25 #26 #27 #28 1/4" Straight Bit 5/16" Straight Bit 3/8" Straight Bit 1/2" Straight Bit 3/4" Straight Bit 1/4" 5/16' 3/8" 1/2" 3/4" Flush | Key Trim lH Hole #13 1/2" FLUSH TRIM 1/2" 1 I #14 3/8" KEY HOLE cuts 3.8 key hole for ■T... O . . ljcc, flush mounting b" °n'v hssi picture frames etc 8.50 WHEN ORDERING ANY 3 OR MORE. DEDUCT $1.00 EACH ALL PRICES POSTAGE PAID Professional Production Quality • 1/2" Ball Bearing Pilot 1/4" Diameter Shanks x 1 %" Long • One Piece Construction Two Flute Thick High Quality Tungsten Carbide Tips To order by Master Charge or Visa Toll Free 7 Day - 24 Hour Order Service Call 1-800-523-2445 Ext. 56 (In PA 1-800-346-7511 Ext. 56) or send check to: MLCS, P.O. Box 53, Rydal, PA 19046 Restoring Antiques by John W. Olson Applying Shellac and Lacquer with a BrushUsing a brush to apply shellac and lacquer, both fast drying finishes, requires a considerable amount of patience and skill if you want to do a good job. Shellac goes on best if a brush is used that allows the finish to flow quickly from the bristles to the surface. Many experienced finishers like to use a soft fitch hair brush, or else one of the China bristles. Generally, a two or three in. brush with medium length bristles works best. Most hardware stores carry four pound cut shellac, but for most applications, a three pound cut works best. To thin a four pound cut to a three pound cut, add two parts denatured alcohol to one part shellac. Shellac at the right viscosity and temperature will have a tendency to level and obliterate brush marks. To apply, dip the brush about halfway into the finish, then swirl it around and fill the bristles so that there will be enough finish to make a continuous covering stroke from one end of the surface to the other. Begin on the side farthest from you so that any drips will be covered by the brush on the subsequent strokes. Be careful to overlap each previous stroke so as to leave no bare spots. Always brush with the grain so any bristle marks left by the brush will tend to fade into the background. Shellac cannot be brushed over at all, so be very careful to completely cover the surface as you go along. As with any quick drying finish, avoid going over the surface a second time as the brush marks and laps will be impossible to remove. For frame and panel construction, the panels should be covered first, then the frames. The outside of drawers and all removeable parts must be coated separately. A few precautions are necessary with shellac. Only white shellac should be used over natural wood finishes, especially light colored woods. Orange shellac may be used over dark finishes. Shellac may be applied only over water or oil stains. Spirit stains will bleed into the finish and give a cloudy, murky or streaked appearance. It can be applied over any filler after it is completely dry. Applying lacquer with a brush requires the same techniques used with shellac. Be sure to use only a water or non-grain raising stain as the solvents in lacquer will attack oil and spirit stains, causing the finish to appear streaked and cloudy. Lacquers may be applied over most fillers when thoroughly dry, although it is a good idea to first use a sanding sealer as the base coat. Some lacquers are marketed as brushing lacquers and come from the manufacturer at the correct viscosity. Others may have to be thinned in order to flow and level properly, and to reduce the effects of evaporation on the viscosity. The solvents in lacquers are, for most part, highly volatile, so every precaution should be taken to work only in a well ventilated area where there are no open flames. Don't smoke while applying lacquer. Don't apply lacquer indoors. Under certain conditions, any source of spark or open flame (such as a hot water heater, furnace or even a light switch) could cause an explosion. A tablespoon or so of lacquer thinner mixed with the proper amount of air can cause a terrific explosion. To protect lungs, wear a respirator designed to catch hydrocarbon particles in the air. Wvj |