Woodworker's Journal 1985-9-2, страница 4

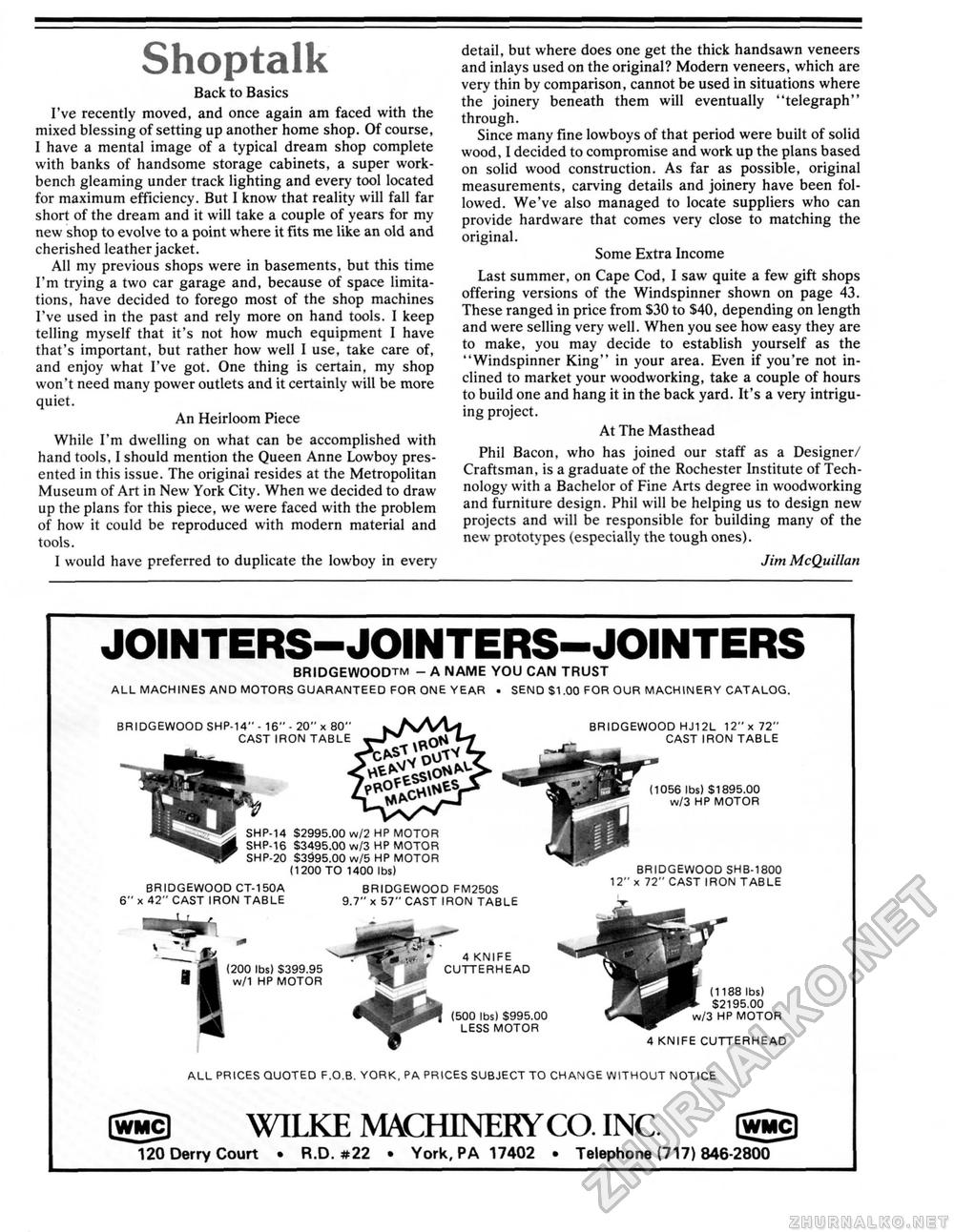

ShoptalkBack to Basics I've recently moved, and once again am faced with the mixed blessing of setting up another home shop. Of course, I have a mental image of a typical dream shop complete with banks of handsome storage cabinets, a super workbench gleaming under track lighting and every tool located for maximum efficiency. But I know that reality will fall far short of the dream and it will take a couple of years for my new shop to evolve to a point where it fits me like an old and cherished leather jacket. All my previous shops were in basements, but this time I'm trying a two car garage and, because of space limitations, have decided to forego most of the shop machines I've used in the past and rely more on hand tools. I keep telling myself that it's not how much equipment I have that's important, but rather how well I use, take care of, and enjoy what I've got. One thing is certain, my shop won't need many power outlets and it certainly will be more quiet. An Heirloom Piece While I'm dwelling on what can be accomplished with hand tools, I should mention the Queen Anne Lowboy presented in this issue. The original resides at the Metropolitan Museum of Art in New York City. When we decided to draw up the plans for this piece, we were faced with the problem of how it could be reproduced with modern material and tools. I would have preferred to duplicate the lowboy in every detail, but where does one get the thick handsawn veneers and inlays used on the original? Modern veneers, which are very thin by comparison, cannot be used in situations where the joinery beneath them will eventually "telegraph" through. Since many fine lowboys of that period were built of solid wood, I decided to compromise and work up the plans based on solid wood construction. As far as possible, original measurements, carving details and joinery have been followed. We've also managed to locate suppliers who can provide hardware that comes very close to matching the original. Some Extra Income Last summer, on Cape Cod, I saw quite a few gift shops offering versions of the Windspinner shown on page 43. These ranged in price from $30 to $40, depending on length and were selling very well. When you see how easy they are to make, you may decide to establish yourself as the "Windspinner King" in your area. Even if you're not inclined to market your woodworking, take a couple of hours to build one and hang it in the back yard. It's a very intriguing project. At The Masthead Phil Bacon, who has joined our staff as a Designer/ Craftsman, is a graduate of the Rochester Institute of Technology with a Bachelor of Fine Arts degree in woodworking and furniture design. Phil will be helping us to design new projects and will be responsible for building many of the new prototypes (especially the tough ones). Jim McQuillan JOINTERS-JOINTERS-JOINTERS BRIDGEWOODTM - A NAME YOU CAN TRUST ALL MACHINES AND MOTORS GUARANTEED FOR ONE YEAR • SEND $1.00 FOR OUR MACHINERY CATALOG. BRIDGEWOOD SHP-14" - 16" - 20" x 80" CAST IRON TABLE . SHP-14 $2995.00 w/2 HP MOTOR SHP-16 $3495.00 w/3 HP MOTOR SHP-20 $3995.00 w/5 HP MOTOR (1200 TO 1400 lbs) BRIDGEWOOD CT-150A 6" x 42" CAST IRON TABLE I m h (200 lbs) $399.95 8 ■ w/1 HP MOTOR BRIDGEWOOD FM250S 9.7" x 57" CAST IRON TABLE 4 KNIFE CUTTERHEAD (500 lbs) $995.00 LESS MOTOR BRIDGEWOOD HJ12L 12"x72" CAST IRON TABLE (1056 lbs) $1895.00 w/3 HP MOTOR BRIDGEWOOD SHB-1800 12" x 72" CAST IRON TABLE (1188 lbs) $2195.00 w/3 HP MOTOR 4 KNIFE CUTTERHEAD ALL PRICES QUOTED F.O.B. YORK, PA PRICES SUBJECT TO CHANGE WITHOUT NOTICE WILKE MACHINERY' CO. INC.120 Derry Court • R.D. #22 • York, PA 17402 • Telephone (717) 846-2800 |