Woodworker's Journal 1985-9-4, страница 42

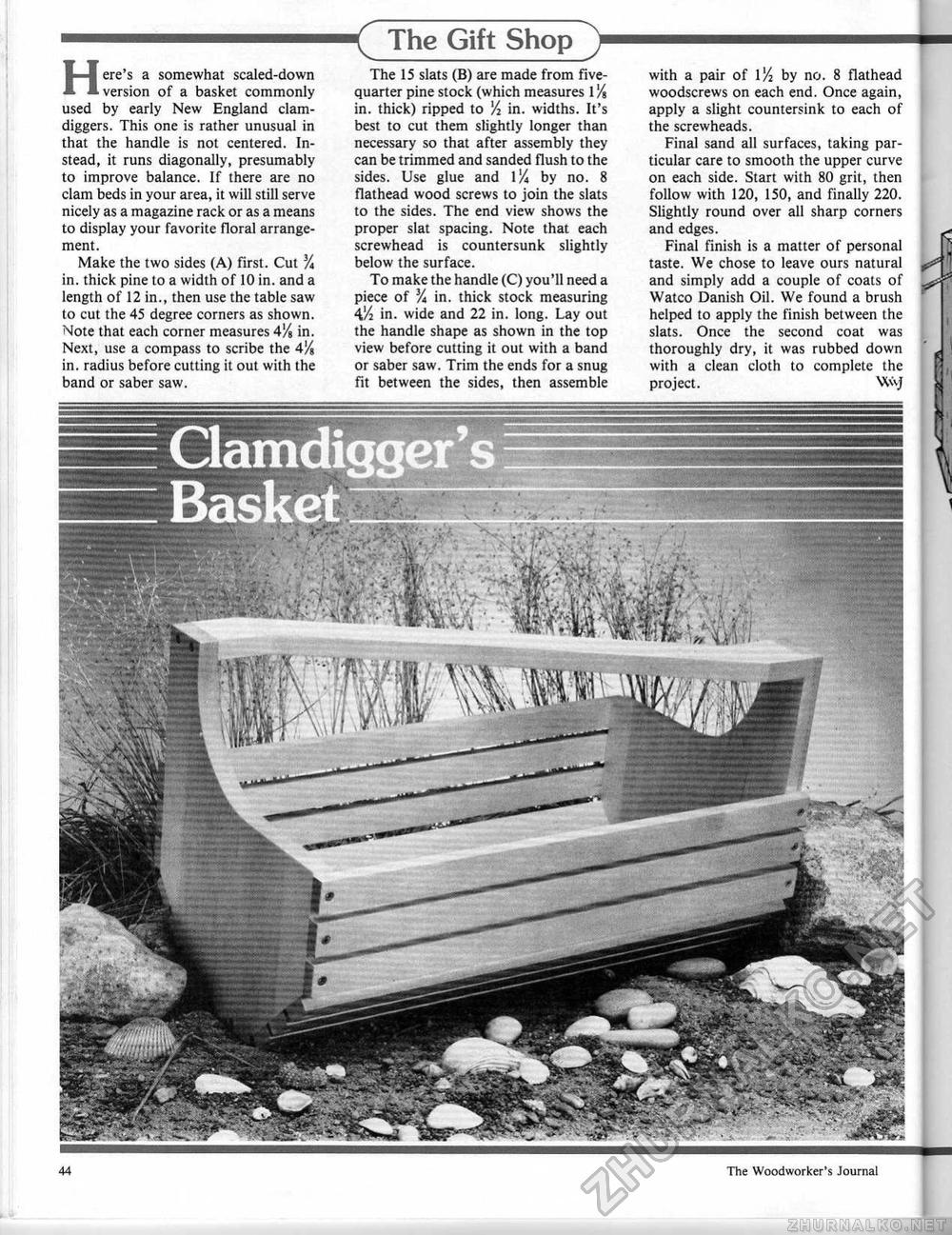

( The Gift Shop ) Here's a somewhat scaled-down version of a basket commonly used by early New England clam-diggers. This one is rather unusual in that the handle is not centered. Instead, it runs diagonally, presumably to improve balance. If there are no clam beds in your area, it will still serve nicely as a magazine rack or as a means to display your favorite floral arrangement. Make the two sides (A) first. Cut % in. thick pine to a width of 10 in. and a length of 12 in., then use the table saw to cut the 45 degree corners as shown. Note that each corner measures 4% in. Next, use a compass to scribe the 414 in. radius before cutting it out with the band or saber saw. The 15 slats (B) are made from five-quarter pine stock (which measures 1 Y» in. thick) ripped to Vj in. widths. It's best to cut them slightly longer than necessary so that after assembly they can be trimmed and sanded flush to the sides. Use glue and 1% by no. 8 flathead wood screws to join the slats to the sides. The end view shows the proper slat spacing. Note that each screwhead is countersunk slightly below the surface. To make the handle (C) you'll need a piece of 3A in. thick stock measuring 4,/2 in. wide and 22 in. long. Lay out the handle shape as shown in the top view before cutting it out with a band or saber saw. Trim the ends for a snug fit between the sides, then assemble with a pair of I'A by no. 8 flathead woodscrews on each end. Once again, apply a slight countersink to each of the screwheads. Final sand all surfaces, taking particular care to smooth the upper curve on each side. Start with 80 grit, then follow with 120, 150, and finally 220. Slightly round over all sharp corners and edges. Final finish is a matter of personal taste. We chose to leave ours natural and simply add a couple of coats of Watco Danish Oil. We found a brush helped to apply the finish between the slats. Once the second coat was thoroughly dry, it was rubbed down with a clean cloth to complete the project. WvJ 44 The Woodworker's Journal |