Woodworker's Journal 1985-9-4, страница 46

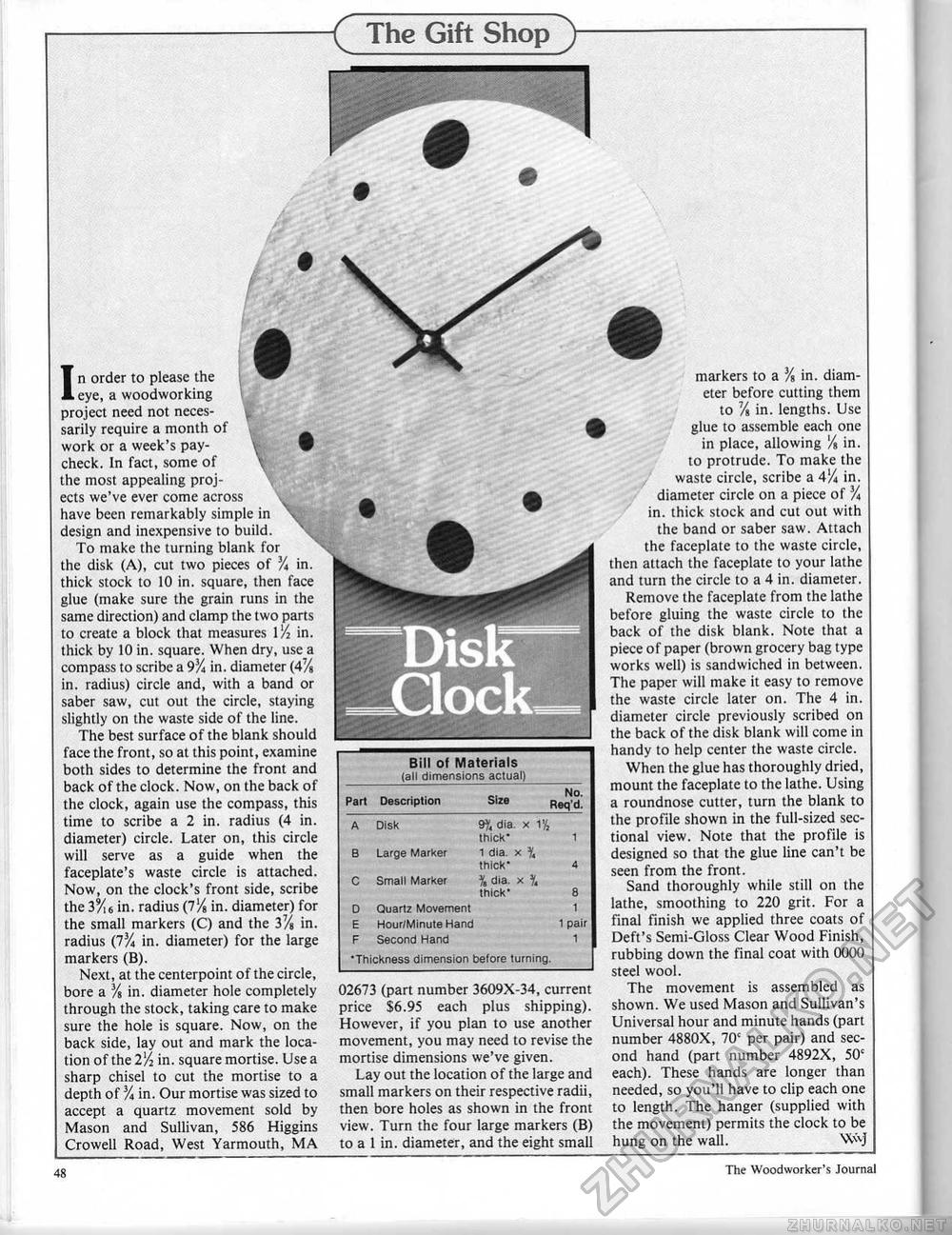

-( The Gift Shop m In order to please the eye, a woodworking project need not necessarily require a month of work or a week's paycheck. In fact, some of the most appealing projects we've ever come across have been remarkably simple in design and inexpensive to build. To make the turning blank for the disk (A), cut two pieces of % in. thick stock to 10 in. square, then face glue (make sure the grain runs in the same direction) and clamp the two parts to create a block that measures 1% in. thick by 10 in, square. When dry, use a compass to scribe a 9% in, diameter (47s in. radius) circle and, with a band or saber saw, cut out the circle, staying slightly on the waste side of the line. The best surface of the blank should face the front, so at this point, examine both sides to determine the front and back of the clock. Now, on the back of the clock, again use the compass, this time to scribe a 2 in, radius (4 in. diameter) circle. Later on, this circle will serve as a guide when the faceplate's waste circle is attached. Now, on the clock's front side, scribe the 39/6 in. radius (7% in. diameter) for the small markers (C) and the 3% in, radius (7% in. diameter) for the large markers (B). Next, at the centerpoint of the circle, bore a % in. diameter hole completely through the stock, taking care to make sure the hole is square. Now, on the back side, lay out and mark the location of the 2Yi in. square mortise. Use a sharp chisel to cut the mortise to a depth of % in. Our mortise was sized to accept a quartz movement sold by Mason and Sullivan, 586 Higgins Crowell Road, West Yarmouth, MA

02673 (part number 3609X-34, current price $6.95 each plus shipping). However, if you plan to use another movement, you may need to revise the mortise dimensions we've given. Lay out the location of the large and small markers on their respective radii, then bore holes as shown in the front view. Turn the four large markers (B) to a 1 in, diameter, and the eight small markers to a % in. diameter before cutting them to % in. lengths. Use glue to assemble each one in place, allowing /8 in. to protrude. To make the waste circle, scribe a 4l/i in. diameter circle on a piece of % in. thick stock and cut out with the band or saber saw. Attach the faceplate to the waste circle, then attach the faceplate to your lathe and turn the circle to a 4 in. diameter. Remove the faceplate from the lathe before gluing the waste circle to the back of the disk blank. Note that a piece of paper (brown grocery bag type works well) is sandwiched in between. The paper will make it easy to remove the waste circle later on. The 4 in. diameter circle previously scribed on the back of the disk blank will come in handy to help center the waste circle. When the glue has thoroughly dried, mount the faceplate to the lathe. Using a roundnose cutter, turn the blank to the profile shown in the full-sized sectional view. Note that the profile is designed so that the glue line can't be seen from the front. Sand thoroughly while still on the lathe, smoothing to 220 grit. For a Final finish we applied three coats of Deft's Semi-Gloss Clear Wood Finish, rubbing down the final coat with 0000 steel wool. The movement is assembled as shown. We used Mason and Sullivan's Universal hour and minute hands (part number 4880X, 70' per pair) and second hand (part number 4892X, 50c each). These hands are longer than needed, so you'll have to clip each one to length. The hanger (supplied with the movement) permits the clock to be hung on the wall, W\J 48 The Woodworker's Journal |

|||||||||||||||||||||||||||