Woodworker's Journal 1985-9-6, страница 12

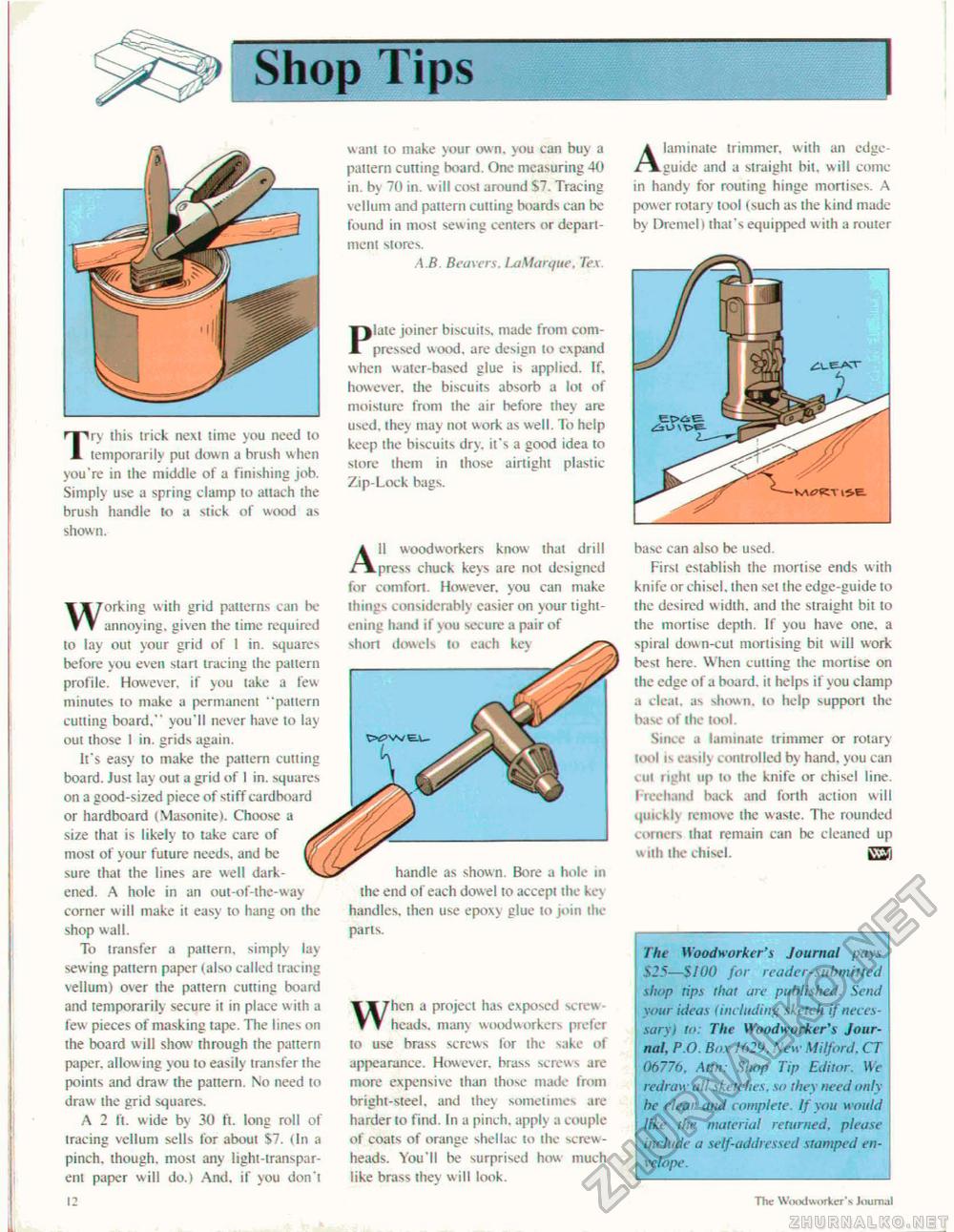

The Woodworker's Journal pays Ji25—$100 for reader-submitted shop tips that a>e published- Send your ideas (including sketch if necessary) to: The Woodworker's Journal, P.O. Box 1629, New Milford. CT 06776. Attn: Shop Tip Editor. W'e redraw all sketches, so they need only be clear and complete. If you would like the material returned, please include a self-addressed stamped envelope. Try (his trick next time you need lo temporarily put down a brush when you're in tile middle of a finishing job. Simply use a spring clamp to attach the brush handle to a stick of wood as shown. Working with grid patterns can be annoying, given the lime required to lay out your grid of 1 in. squares before you even start tracing the pattern profile. However, if you take a few minutes to make a permanent '"pattern cutting board," you'll never have to lay out those I in. grids again. it's easy to make the pattern cutting board. Just lay out a grid of 1 in. squares on a good-sized piece of stiff cardboard or hardboard (Masonite). Choose a size that is likely to take care of most of your future needs, and be sure that the lines are well darkened. A hole in an out-of-the-way corner will make it easy to hang on the shop wall. To transfer a pattern, simply lay sewing pattern paper (also called tracing vellum) over llie pattern cutting board and temporarily secure it in place w ith a few pieces of masking tape. The lines on the board will show through the pattern paper, allowing you to easily transfer the points and draw the pattern. No need to draw the grid squares. A 2 ft. wide by 30 ft. long roll of tracing vellum sells lor about $7. (In a pinch, though, most any lighl-lranspar-ent paper will do.) And. if you don't A laminate trimmer, with an edge-guide and a straight bit, will come in handy for routing hinge mortises. A power rotary tool (such as the kind made by Dremel I that's equipped with a router base can also be used. First establish the mortise ends with knife or chisel, then set the edge-guide to the desired width, and the straight bit lo the mortise depth. If you have one. a spiral down-cut mortising bit will work best here. When cutting the mortise on the edge of a board, it helps if you clamp a cleat, as shown, lo help support the hase of the too). Sinee a laminate trimmer or rotary i»n<l is easilj controlled by hand, you can cut right up to the knife or chisel line. Freehand back and forth action will quickl) remove ihe waste. The rounded corners that remain can be cleaned up Willi the chisel. j£3j want 10 make your own. you can buy a pattern cutting board. One measuring 40 in. by 70 in. w ill cosi around S7. Tracing vellum and pattern culling boards can he found in mosl sew ing centers or department stores. A.B. Beavers. LaMarque. Tex. Plate joiner biscuits, made from compressed wood, are design lo expand when water-based glue is applied. If. however, the biscuits absorb a lot of moisture from the air before they are used, they may not work as well. To help keep the biscuits dry. it's a good idea to store them in those airtight plastic Zip-Lock bags. All woodworkers know that drill press chuck keys are not designed for comfort. However, you can make things considerably easier on your tightening hand if you secure a pair of short dowels lo each key handle as shown. Bore a hole in the end of each dowel lo accept the ke\ handles, then use epoxy glue lo join the pans. When a project has exposed screw ■ heads, mam woodworkers prefer to use brass screws for ihe sake of appearance. However, brass screws are more expensive than those made from bright-steel, and they sometimes are harder to find. In a pinch, apply a couple of coats of orange shellac to the screw -heads. You'll be surprised how much like brass they will look. •4K The Woodworker'?. Journal |