Woodworker's Journal 1986-10-4, страница 15

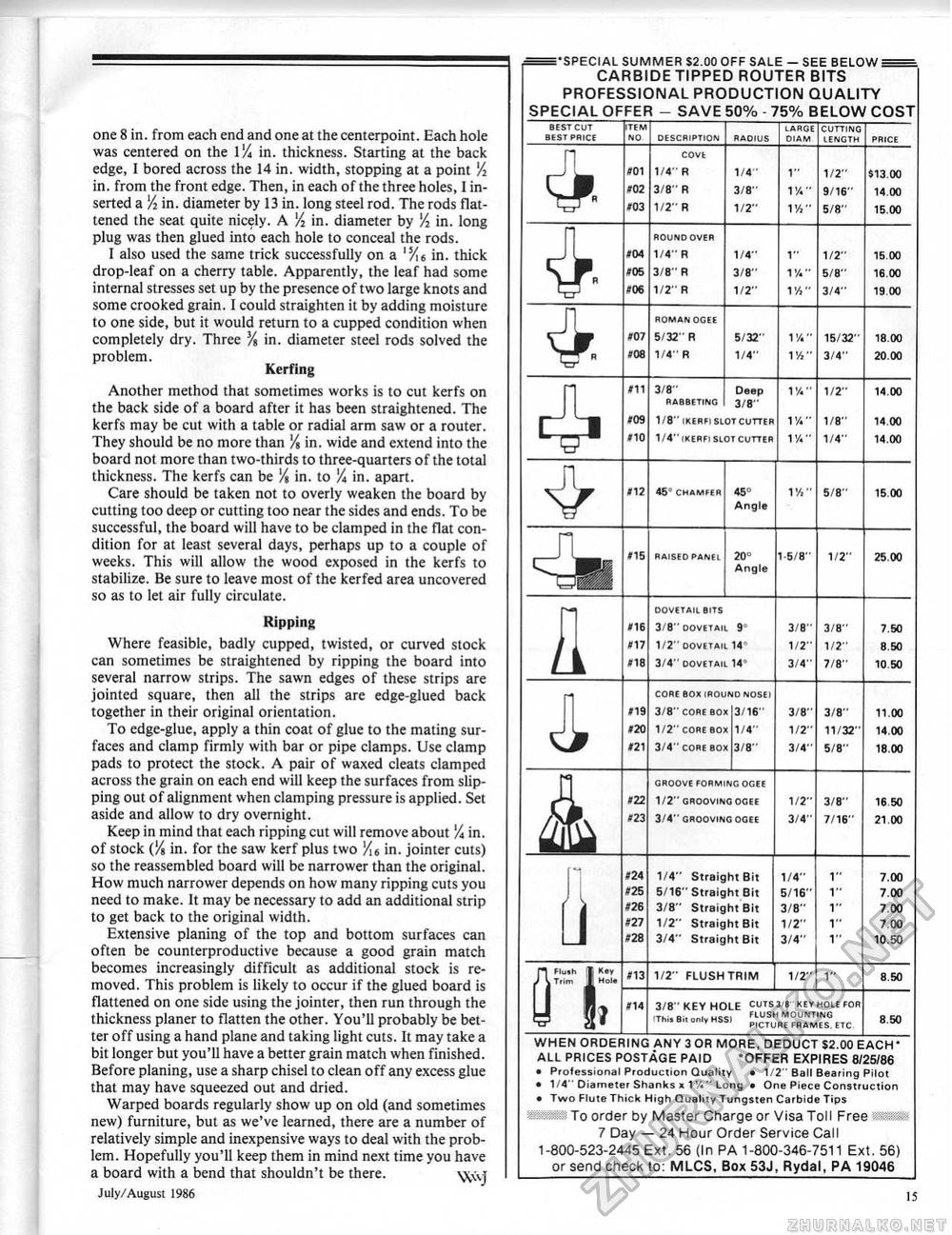

one 8 in. from each end and one at the centerpoint. Each hole was centered on the 1% in. thickness. Starting at the back edge, I bored across the 14 in. width, stopping at a point A in, from the front edge. Then, in each of the three holes, 1 inserted a lA in. diameter by 13 in. long steel rod. The rods flattened the seat quite nicely. A 'A in. diameter by A in. long plug was then glued into each hole to conceal the rods. I also used the same trick successfully on a in. thick drop-leaf on a cherry table. Apparently, the leaf had some internal stresses set up by the presence of two iarge knots and some crooked grain. I could straighten it by adding moisture to one side, but it would return to a cupped condition when completely dry. Three % in. diameter steel rods solved the problem. Kerfing Another method that sometimes works is to cut kerfs on the back side of a board after it has been straightened. The kerfs may be cut with a table or radial arm saw or a router. They should be no more than Yt in. wide and extend into the board not more than two-thirds to three-quarters of the total thickness. The kerfs can be 'As in. to % in. apart. Care should be taken not to overly weaken the board by cutting too deep or cutting too near the sides and ends. To be successful, the board will have to be clamped in the fiat condition for at least several days, perhaps up to a couple of weeks, This will allow the wood exposed in the kerfs to stabilize. Be sure to leave most of the kerfed area uncovered so as to let air fully circulate. Ripping Where feasible, badly cupped, twisted, or curved stock can sometimes be straightened by ripping the board into several narrow strips. The sawn edges of these strips are jointed square, then all the strips are edge-glued back together in their original orientation. To edge-glue, apply a thin coat of giue to the mating surfaces and clamp firmly with bar or pipe clamps. Use clamp pads to protect the stock. A pair of waxed cleats clamped across the grain on each end will keep the surfaces from slipping out of alignment when clamping pressure is applied. Set aside and allow to dry overnight. Keep in mind that each ripping cut will remove about % in. of stock in. for the saw kerf plus two VJ6 in. jointer cuts) so the reassembled board will be narrower than the original. How much narrower depends on how many ripping cuts you need to make. It may be necessary to add an additional strip to get back to the original width. Extensive planing of the top and bottom surfaces can often be counterproductive because a good grain match becomes increasingly difficult as additional stock is removed. This problem is likely to occur if the glued board is flattened on one side using the jointer, then run through the thickness planer to flatten the other. You'll probably be better off using a hand plane and taking light cuts. It may take a bit longer but you'll have a better grain match when finished. Before planing, use a sharp chisel to clean off any excess glue that may have squeezed out and dried. Warped boards regularly show up on old (and sometimes new) furniture, but as we've learned, there are a number of relatively simple and inexpensive ways to deal with the problem. Hopefully you'll keep them in mind next time you have a board with a bend that shouldn't be there. NX\\j July/August 1986 ==f'SPECIAL SUMMER S2.00 OFF SALE - SEE BELOW^= CARBIDE TIPPED ROUTER BITS PROFESSIONAL PRODUCTION QUALITY SPECIAL OFFER - SAVE 50% 75% BELOW COST n 41 n <M [j Flu»h J Kay Trim I Hala ITEM NO #oi #02 #os #04 #05 #06 DESCRIPTION COVt 1/4" R 3/8" R 1/2" R round over 1/4" R 3/B" R 1/2" R #07 #08 #11 #09 #10 #12 #15 #16 #17 #18 #19 #20 #21 #22 #23 #24 #25 #26 #27 #28 #13 #14 roman ogee 5/32" R 1/4" R 3/8" RABBETING 1/4" 3/8" 1/2" 1/4" 3/B" 1/2" 5/32" 1/4" Deep 3/8" 1/8" (kerfi slot cutter 1/4"<kerfi slot cutter 45' CHAMFER RAISED PANEL 45" Angle 20° Angle dovetail sits 3/B" dovetail 9° 1/2" dovetail 14" 3/4" dovetail 14° core sox (round nose) 3/8" core bo* 1/2" core bo* 3/4" core aox 3/16" 1/4" 3/8" groove fohming ogee 1/2" grooving ogee 3/4" grooving ogee 1/4" Straight Bit 5/16" Straight Bit 3/8" Straight Bit 1/2" Straight Bit 3/4" Straight Bit 1/2" FLUSH TRIM LARGE DIAM 1" 1 % " IV 1" IV CUTTING LENGTH 1/2" 9/16" 5/8" 1/2" 5/8" 3/4" IV 15/32" IV 3/4" 1 % " 1V." 1 %" 1V>' 1-5/8' 3/6" 1/2" 3/4" 3/8' 1/2' 3/4' 1/2' 3/4' 1/4" 5/16' 3/6" 1/2" 3/4" 1/2" 1" 1/2" 1/8" 1/4" 5/8" 1/2" 3/B" 1/2" 7/8" 3/8" 11/32' 5/8" 3/B" 7/16" 3/8" KEY HOLE CUTS 3/B" KEVHOL.1 FOR ,Thi. B„ „„,„ H„. FLUSH MOUNTING Th" B" Dn"HSS) PICTURE FRAMES. ETC $13.00 14 00 15.00 WHEN ORDERING ANY 30R MORE, DEDUCT $2,00 EACH-ALL PRICES POSTAGE PAID 'OFFER EXPIRES W25/86 • Professional Production Quality • 1/2" Ball Bearing Pilot • 1/4" Diameter Shanks x 1 %' Long ■ One Piece Construction • Two Flute Thick High Quality Tungsten Carbide Tips »::•.:..:• To order by Master Charge or Visa Toll Free mm 7 Day — 24 Hour Order Service Call 1-800-523-2445 Ext. 56 (In PA 1-800-346-7511 Ext. 56) or send check to: MLCS, Box 53J, Rydal, PA 19046 15.00 16.00 19.00 18.00 20.00 14,00 14.00 14.00 15.00 25.00 7,50 8.50 10.50 11.00 14.00 18.00 16,50 21.00 7.00 7.00 7.00 7.00 10.50 8.50 8.50 15 |