Woodworker's Journal 1986-10-4, страница 51

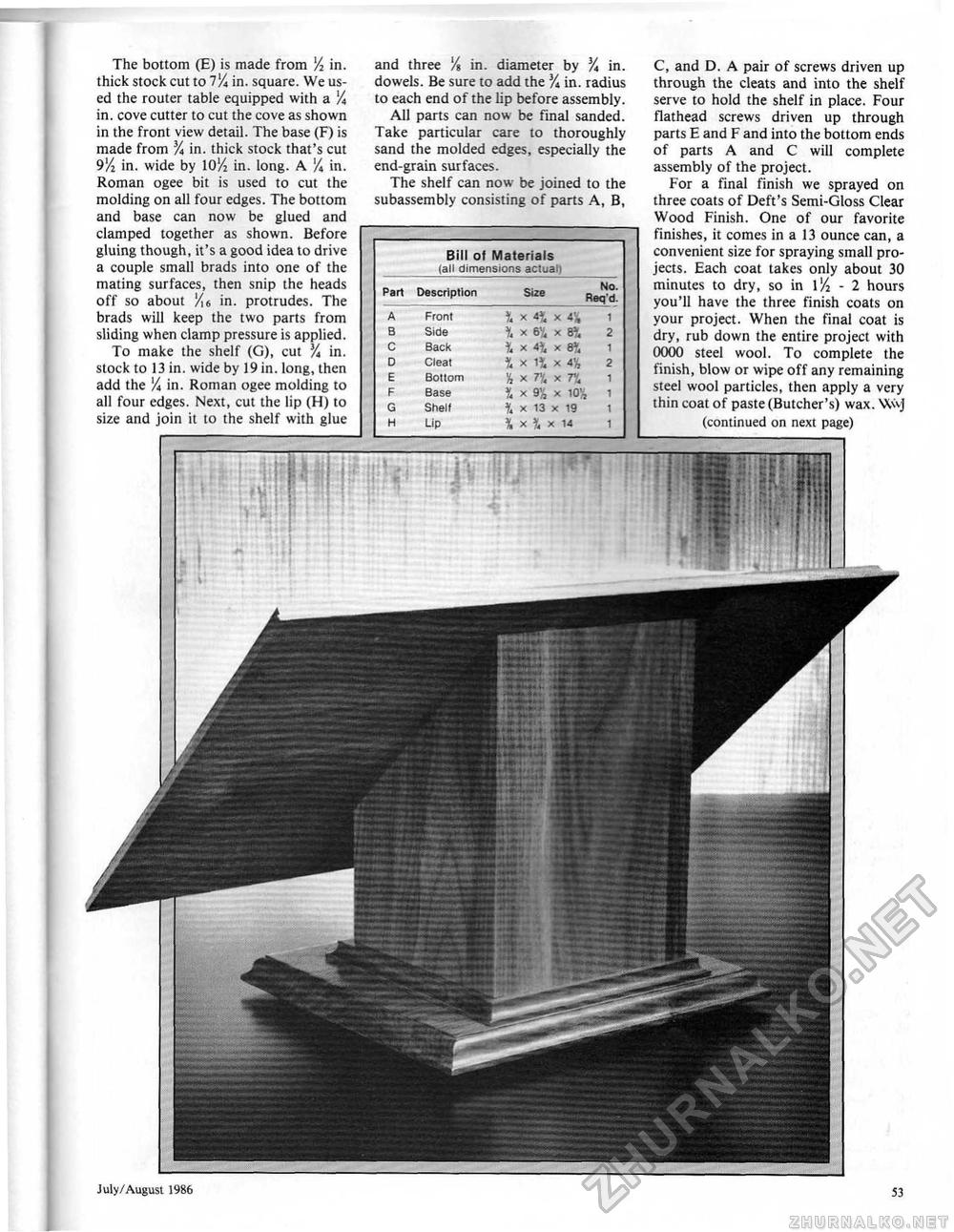

The bottom (E) is made from l/2 in. thick stock cut to llA in, square. We used the router table equipped with a % in, cove cutter to cut the cove as shown in the front view detail. The base (F) is made from % in. thick stock that's cut 9'/z in. wide by 10J4 in. long. A Vi in. Roman ogee bit is used to cut the molding on all four edges. The bottom and base can now be glued and clamped together as shown. Before gluing though, it's a good idea to drive a couple small brads into one of the mating surfaces, then snip the heads off so about M6 in. protrudes. The brads will keep the two parts from sliding when clamp pressure is applied. To make the shelf (G), cut % in. stock to 13 in. wide by 19 in. long, then add the 'A in. Roman ogee molding to all four edges. Next, cut the lip (H) to size and join it to the shelf with glue C, and D. A pair of screws driven up through the cleats and into the shelf serve to hold the shelf in place. Four flathead screws driven up through parts E and F and into the bottom ends of parts A and C will complete assembly of the project. For a final finish we sprayed on three coats of Deft's Semi-Gioss Clear Wood Finish. One of our favorite finishes, it comes in a 13 ounce can, a convenient size for spraying small projects. Each coat takes only about 30 minutes to dry, so in l'/2 - 2 hours you'll have the three finish coats on your project. When the final coat is dry, rub down the entire project with 0000 steel wool. To complete the finish, biow or wipe off any remaining steel wool particles, then apply a very thin coat of paste (Butcher's) wax. Wvj (continued on next page) and three % in. diameter by % in. dowels. Be sure to add the % in. radius to each end of the hp before assembly. All parts can now be final sanded. Take particular care to thoroughly sand the molded edges, especially the end-grain surfaces. The shelf can now be joined to the subassembly consisting of parts A, B, Bill of Materials fail dimensions acluali Part Description Size Bill of Materials fail dimensions acluali Part Description Size

J uly/August 1986 53 |