Woodworker's Journal 1992-16-5, страница 10

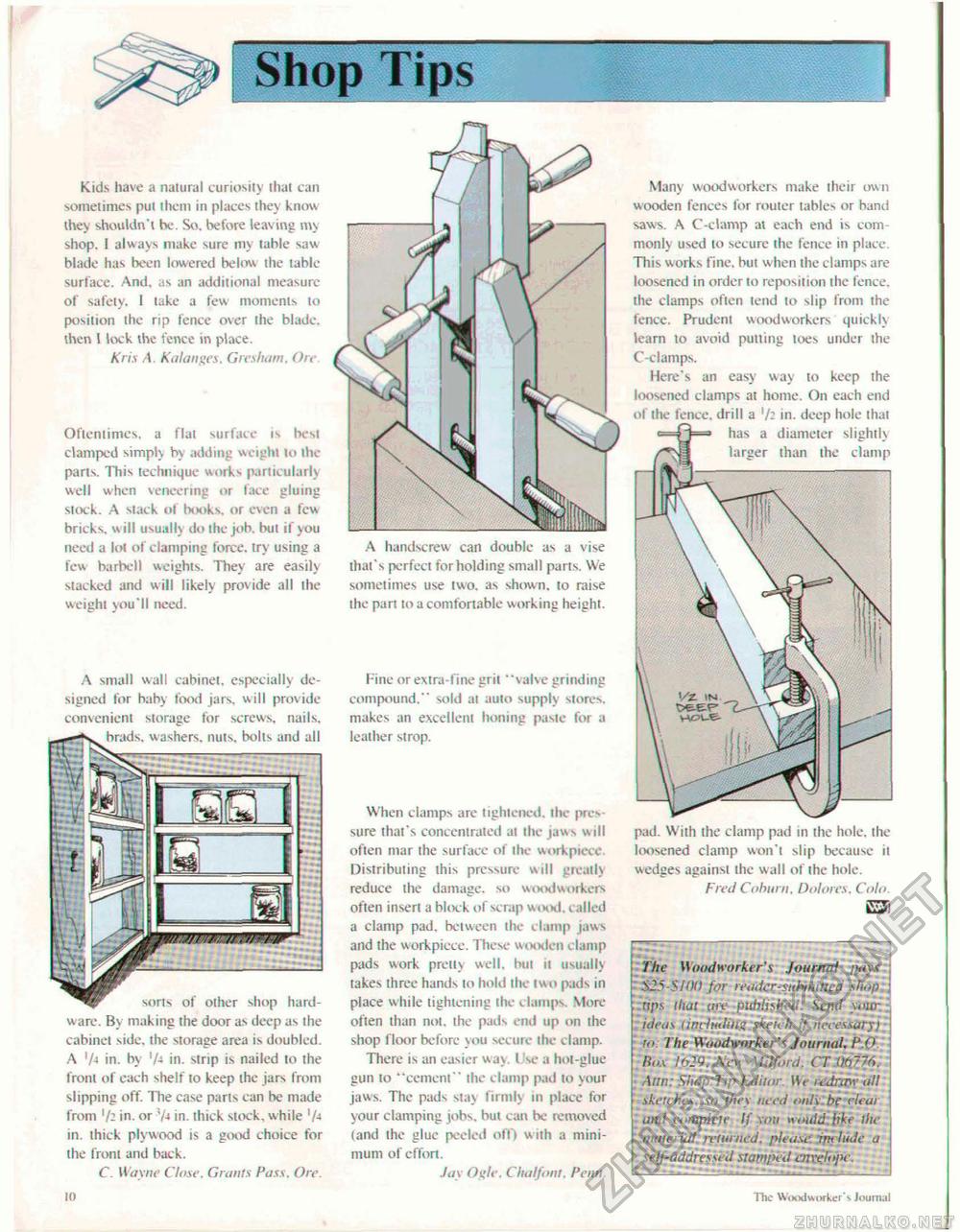

Kids have a natural curiosity that can sometimes put ihcni in places they know they shouldn't he. So. before leaving my shop. 1 always make sure my table saw blade has been lowered below the table surface. And, as an additional measure of safety, I take a few moments to position the rip fence over the blade, then I lock the fence in place. Kris A Kalanges. Gresham, Ore Oftentimes, a flat surface is best clamped simply h\ adding weight to the parts. Tliis technique works particularly well when veneering or face gluing slock. A slack of books, or even a few bricks, v. ill usually do the job. but if you need a loi of clamping force, try using a few barbell weights. They are easily stacked and will likely provide all the weight you'll need. A handscrew can double as a vise that's perfect for holding small parts. We sometimes use two. as shown, to raise the part to a comfortable working height. Fine or extra-fine grit "valve grinding compound." sold at auto supply stores, makes an excellent boning paste for a leather strop. When clamps are tightened, the pics-sure that's concentrated at the jaws will often mar the surface of ihe workpiecc. Distributing this pressure will grcall} reduce the damage, so woodworkers often insert a block of scrap wood, i ailed a clamp pad, between the clamp jaws and the workpicce. These wooden clamp pads work preuy well, but it usually takes three hands to hold the two pads in place w hile tightening the clamps. More often than not. the pads end up on the shop floor before you secure the clamp. There is an easier way. I \e a hot-glue gun to "cement" the clamp pad to your jaws. The puds staj firmly in place for your clamping jobs, but can be removed (and ihe glue peeled off) with a minimum of effort. Jay Ogle, Chalfonr. Penn. Many woodworkers make their own wooden fences for router tables or hand saws. A C-clamp at each end is commonly used to secure the fence in place. This works fine, but when the clamps are loosened in order to reposition the fence, the clamps often tend to slip from the fence. Prudent woodworkers quickly learn to avoid putting toes under the C-c lamps. Here's an easy way to keep the loosened clamps at home. On each end of the fence, drill a '/: in. deep hole that has a diameter slightly larger than the clamp pad. With the clamp pad in the hole, the loosened clamp won't slip because it wedges against the wall of the hole. Fred Cnburn, Dolores. Colo. The Woodworker's Journal /*/>* $25 $WO for readcr-sttbtiiined shop; rips ilia! oie puhljflht'd. Send your ideas {including sketch if nccessarjj to. The Woodworker's Journal, P.0 Box I<t!9. A*m Milford. CT 1)0776. Attn: Shop Tip Editor. We redtmv all sketches, so. they need only.be clear uml complete If you woidd file the moteriirf returned, please im lude a self-addressed stamped atrelope. A small wail cabinet, especially designed for haby food jars, will provide convenient storage for screws, nails, brads, washers, nuts, bolls and all - sorts of other shop hardware. By making the door as deep as the cabinet side, the storage area is doubled. A 'A in. by in. strip is nailed to the front of each shelf to keep the jars from slipping off. The case parts can he made from '/: in. or V-i in. thick stock, while 'A in. thick plywood is a good choice for ihe front and back. C. Wavne Close. Grants Pass. Ore. 10 The Wot*iwori.er\ Journal |