Woodworker's Journal 1992-16-5, страница 42

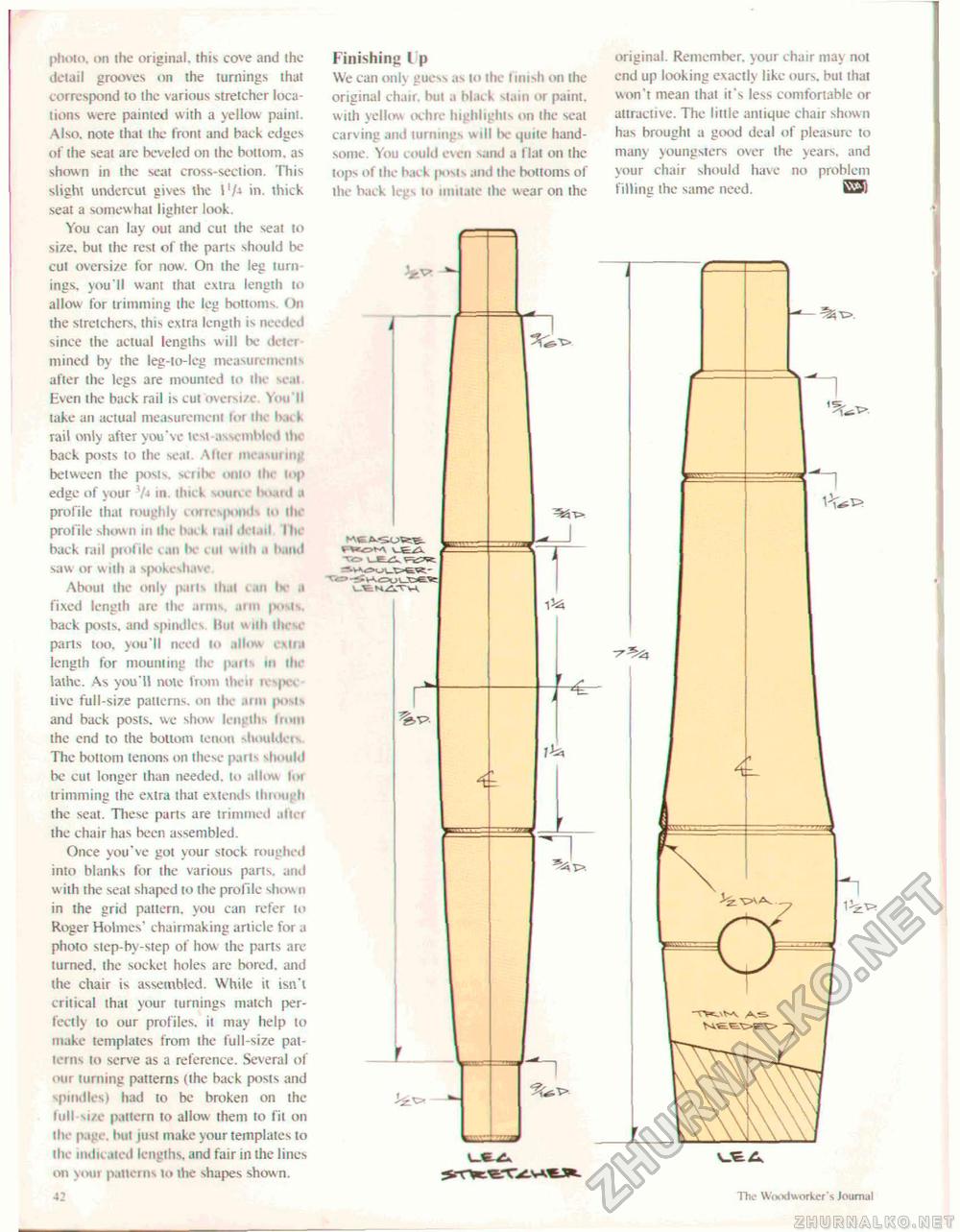

photo, on the original, this cove and the detail grooves on the turnings that correspond to the various stretcher locations were painted with a yellow paint. Also, note that the front and back edges of the seat are beveled on the bottom, as shown in the seat cross-section. This slight undercut gives the \1/a in. thick seat a somewhat lighter look. You can lay out and cut the seat to size, but the rest of the parts should be cut oversize for now. On the leg turn ings. you'll want that extra length to allow for trimming the leg bottoms. On the stretchers, this extra length ts needed since the actual lengths will be detei mined by the leg-to-leg measurements after the legs are mounted to tin- seat Even the back rail is cut oversize You il take an actual measurement lor the b;n k rail only after you've lest assembled the back posts to the seal Altei im * mm; between the posts, scnhc onto tlx lop edge of your '/■> in. thick si urn e UmhI a profile that roughly cortesjtonds I" tin* profile shown in the bat. k Mil detail I he back rail profile can he cut wtlh a baud saw or with a spokeshave About the only purls that can he a fixed length are the arms, arm posts, back posts, and spindles Rut with these parts loo, you'll need to alien* extra length for mounting the pari in Ihe lathe. As you'll note from then i< sjvt live full-size patterns, on the aim pt>sis and back posts, we show lengths from the end to the bottom tenon sltouldct • The bottom tenons on these p.uis shoul'l be cut longer than needed, to allow loi trimming the extra that extends ihi>'ii;li the seat. Tltese parts are trimmed afln the chair has been assembled. Once you've got your slock roughed into blanks for the various parts, and w ith the seat shaped to the profile shown in the grid pattern, you can refer to Roger Holmes' chairmaking article for a photo step-by-step of how the parts arc turned, the socket holes are bored, and ihe chair is assembled. While it isn't critical that your turnings match perfectly lo our profiles, it may help to make templates from the full-size patterns to serve as a reference. Several of our turning patterns (the back posts and spindles) had to be broken on the full-si/e pattern to allow them to fit on the page, but mm make your templates to the indicated lengths, and fair in the lines on youi patterns to the shapes show n. Finishing I p We can only guess as to the finish oil the original chair, but a black stain or paint, with yellow ochre highlights on ihe seat carving and turnings will be quite handsome. You could even sand a flat on ihe tops of ihe hai k posts and the bottoms of the back legs to imitate ihe wear on the original. Remember, your chair may not end up looking exactly like ours, hut that won't mean that it's less comfortable or attractive. The little antique chair shown has brought a good deal of pleasure to many youngsters over the years, and your chair should have no problem fiiting the same need. l£fi9D 42 Thi' Woodworker's Journal |