Woodworker's Journal 1992-16-6, страница 73

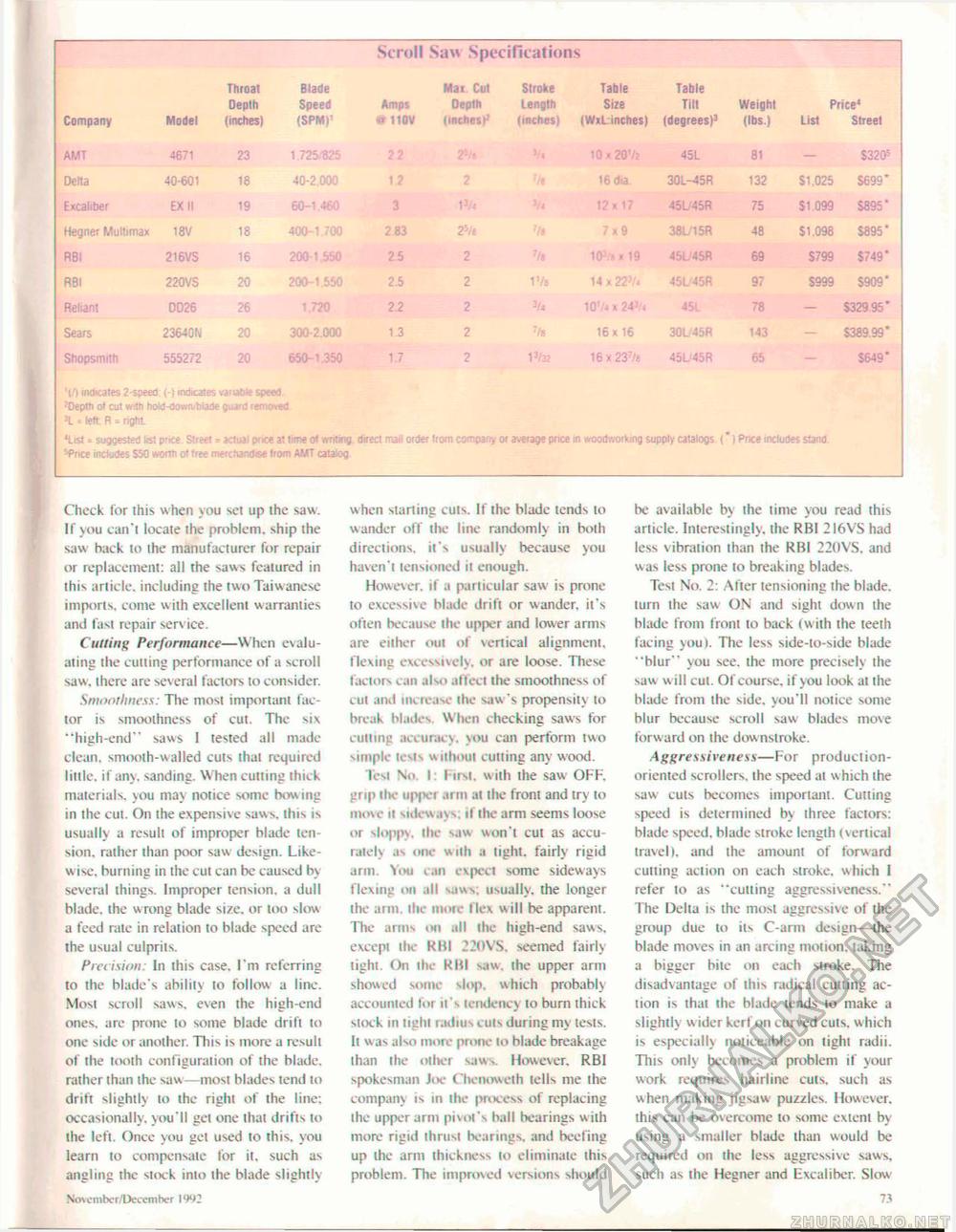

Scroll Saw Specifications

V) indicates 2-speec H indicates variable speed 'Depth at cut wrtti hotd-dovm blade guard removed S. - left R = right V) indicates 2-speec H indicates variable speed 'Depth at cut wrtti hotd-dovm blade guard removed S. - left R = right list» suggested 1st price Street - actual prce at time ot writing direct mail order from company or average price in woodworking supply catalogs (*) Pnce includes stand. ^Pnce includes S5G worm ot tree merctiandse from AMT catalog Check for this when you set up the saw. If vou can't locate the problem, ship the saw hack to ihe manufacturer for repair or replacement: all the saws featured in this article, including the two Taiwanese imports, come with excellent warranties and fast repair service. Culling Performance—When evaluating the cutting performance of a scroll saw. there are several factors to consider. Smoothness: The most important factor is smoothness of cut. The six "high-end" saws I tested all made clean, smooth-walled cuts that required little, if any, sanding. When cutting thick materials, you may notice some bow ing in ihe cut. On the expensive saws, this is usually a result of improper blade tension. rather than poor saw design. Like-w ise. burning in the cut can be caused by several things. Improper tension, a dull blade, the wrong blade size, or too slow a feed rate in relation to blade speed are the usual culprits. Precision: In this case. I'm referring to the blade's ability to follow a line. Most scroll saws, even the high-end ones, are prone to some blade drift lo one side or another. This is more a result of the tooth configuration of the blade, rather than the saw —most blades tend to drift slightly to the right of the line: occasionally, you'll get one that drifts to the left. Once you get used to this, you learn to compensate for it. such as angling the stock into the blade slightly Novcmber/December l<W2 when starling cuts. If the blade tends to wander off the line randomly in both directions, it's usually because you haven't tensioned it enough. However, if a particular saw is prone to excessive blade drift or wander, it's often because the upper and lower arms are either out of vertical alignment, flexing excessively, or are loose. These factor-* can also affect the smoothness of cut and increase the saw s propensity to break blades When checking saws for cutting accuracy. you can perform two simple tesis without cutting any wood. Test No. I: First, wilh the saw OFF. grip the upper arm al ihe front and try to move ii sidewavs if the arm seems loose or sloppy the saw won't cut as accu-ratelv as one wilh a light, fairly rigid arm. You can expect some sideways flexing on all s.iwv usually, the longer ihe arm. the more flex will be apparent. The arms on ill ihe high-end saws, except the RBI 220VS, seemed fairly tight. On the RBI saw, the upper arm showed some slop, which probably accounted lor it s tendency to burn thick Stock in light radius cuts during my tests. It was also more prone lo blade breakage than the other saw,. However. RBI spokesman Joe Chenoweth tells me the company is in the process of replacing the upper arm pivot's ball hearings with more rigid throat bearings, and beefing up the arm thickness 10 eliminate this problem. The improved versions should be available by the time you read this article. Interestingly, the RBI 2I6VS had less vibration than the RBI 220VS. and was less prone to breaking blades. Test No. 2: After tensioning the blade, turn the saw ON and sight down the blade from front to back (with the teeth facing you). The less side-to-side blade "blur" you see. the more precisely the saw w ill cut. Of course, if you look at the blade from the side, you'll notice some blur because scroll saw blades move forward on the downsiroke. Aggressiveness—For production-oriented scrollers, the speed at which the saw cuts becomes important. Cutting speed is determined by three factors: blade speed, blade stroke length (vertical travel), and the amount of forward cutting action on each stroke, which I refer to as "cutting aggressiveness." The Delta is the most aggressive of the group due to its C-arm design—the blade moves in an arcing motion, taking a bigger bite on each stroke. The disadvantage of this radical cutting action is that the blade lends to make a slightly wider kerf on curved cuts, which is especially noticeable on tight radii. Tins only becomes a problem if your work requires hairline cuts, such as when making jigsaw puzzles. However, this can be overcome to some extent by using a smaller blade than would be required on the less aggressive saws, such as the Hegner and Excaliber. Slow 73 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||