Woodworker's Journal 1993-17-1, страница 12

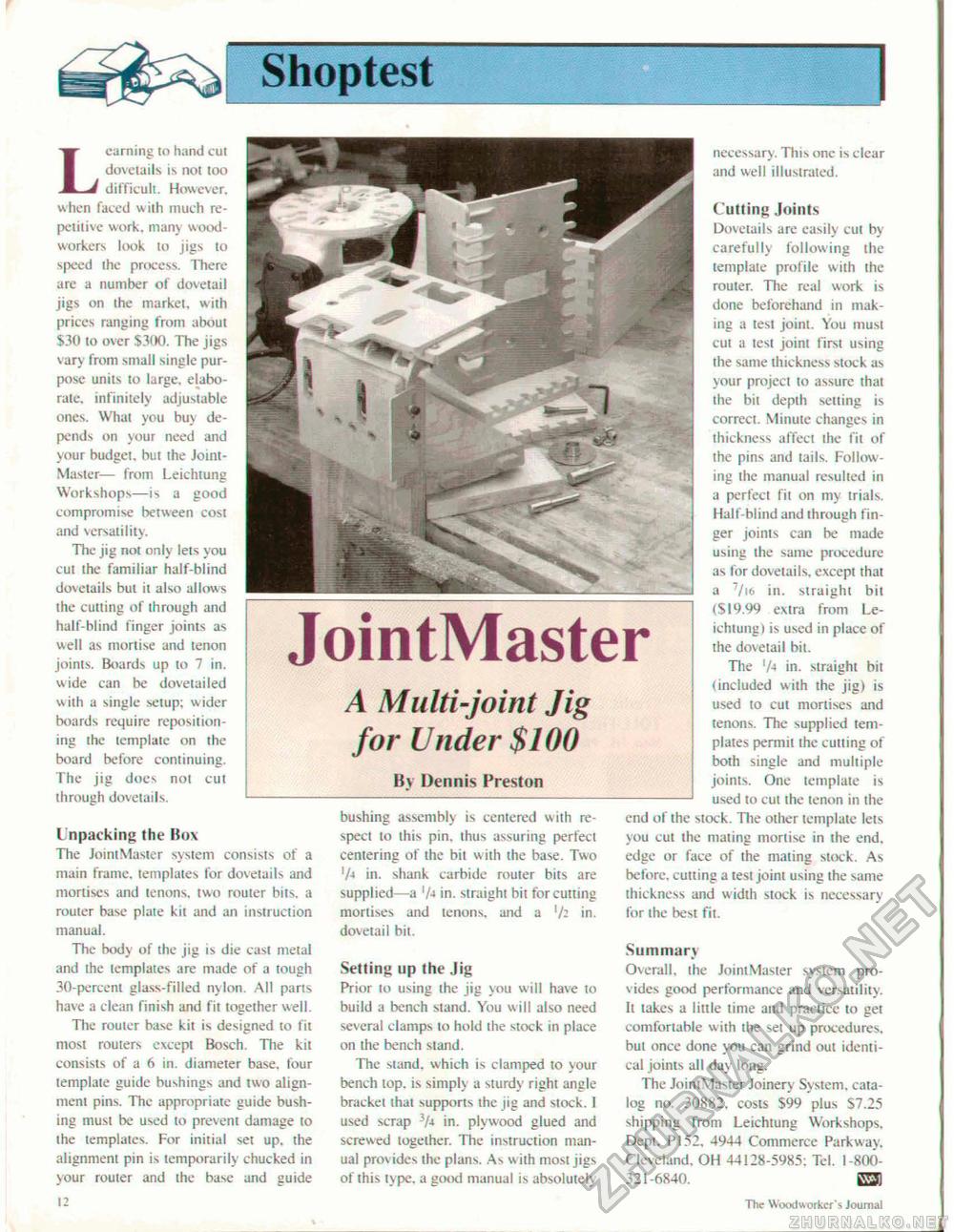

Learning to hand cut dovetails is not too difficult. However, when faced wiih much repetitive work, many woodworkers Ux)k to jigs to speed the process. There are a numl>er of dovetail jigs on the market, with prices ranging from about $30 to over $300. The jigs vary from small single purpose units to large, elaborate. infinitely adjustable ones. What you buy depends on your need and your budget, but the Joint-Master— from Leichtung Workshops—is a good compromise between cost and versatility. The jig not only lets you cut the familiar half-blind do\etails but il also allows ihe cutting of through and half-blind finger joints as well as mortise and tenon joints. Boards up to 7 in. wide can be dovetailed w ith a single setup; wider boards require repositioning ihe template on the board before continuing. The jig docs not cut through dovetails. JointMaster A Multi-joint Jig for Under $100 By Dennis Preston Unpacking Ihe liov The JointMaster system consists of a main frame, templates for dovetails and mortises and tenons, two router bits, a router base plate kit and an instruction manual. The body of the jig is die cast metal and the templates are made of a tough 30-perceni glass-filled nylon. All parts have a clean finish and fit together well. The router base kit is designed to fit most routers except Bosch. The kit consists of a 6 in. diameter base, four template guide bushings and two alignment pins. The appropriate guide bushing must be used lo prevent damage to ihe templates. For initial set up, the alignment pin is temporarily chucked in your router and the base and guide bushing assembly is centered with respect to this pin. thus assuring perfect centering of the bit w ith the base. Two '/4 in. shank carbide router bits are supplied—a '/-»in. straight bit tor cutting mortises and tenons, and a '/2 in. dovetail bit. Setting up the Jig Prior to using ihe jig you will have to build a bench stand. You will also need several clamps to hold the stock in place on the bench siand. The siand, which is clamped to your bench top. is simply a sturdy right angle bracket that supports the jig and slock. I used scrap 3A in. plywood glued and screwed together. The instruction manual provides the plans. As with most jigs of this type, a good manual is absolutely Cutting Joints Dovetails are easily cut by carefully following ihe template profile with the router. The real work is done beforehand in making a test joint. You must cut a lest joint first using the same thickness stock as your project to assure that the bit depih setting is correct. Minute changes in thickness affect the fit of the pins and tails. Following the manual resulted in a perfect fit on my trials. Half-blind and through finger joints can be made using the same procedure as for dovetails, except that a /in. straight bit ($19.99 exlra from Leichtung) is used in place of the dovetail bit. The '/•» in. straight bit (included with the jig) is used to cut mortises and tenons. The supplied templates permit the cutting of both single and multiple joints. One template is used to cut the tenon in the end of the slock. The other template lets you cut the mating inorlisc in the end. edge or face of the mating stock. As before, cutting a test joint using the same thickness and width stock is necessary for ihe best fit. Summary Overall, the JointMaster system provides good performance and versatility. Il takes a little time and practice to get comfortable with the set up procedures, but once done you can grind out identical joints all day long. The JointMaster Joinery System, catalog no. 30882, costs S99 plus $7.25 shipping from Leichtung Workshops, Dept. PI52. 4944 Commerce Parkway. Cleveland. OH 44128-5985: Tel. 1-800321-6840. ES necessary. This one is clear and well illustrated. IX The Woodworker'1, Journal |