Woodworker's Journal 1993-17-5, страница 14

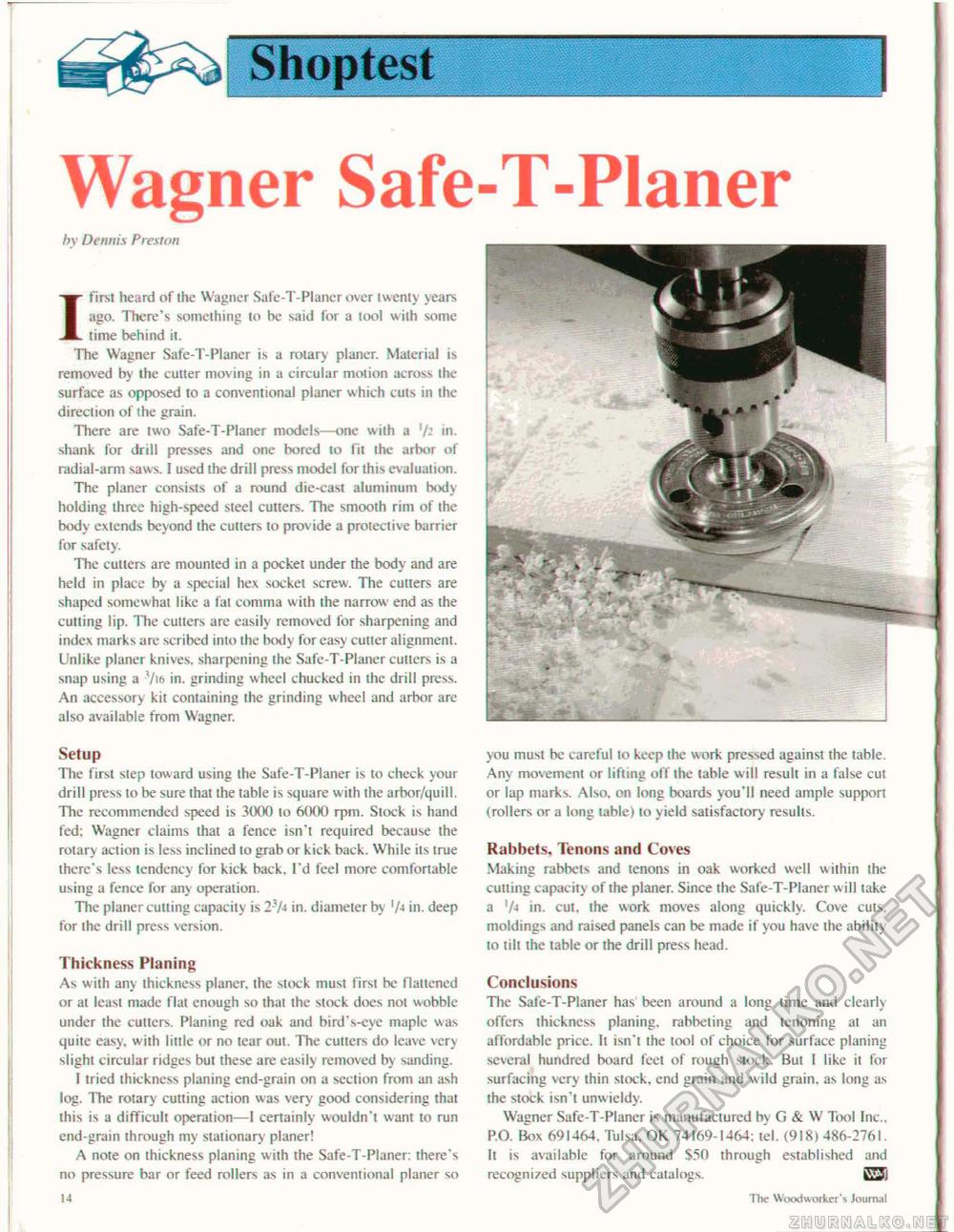

Wagner Safe by Dennis Preston I first heard of the Wagner Safe-T-Planer over twenty years ago. There's something to he said for a tool with some _ time behind it. The Wagner Safe-T-Planer is a rotary planer. Material is removed by the cutter moving in a circular motion across the surface as opposed to a conventional planer which cuts in the direction of the grain. There are two Safe-T-Planer models—one with a in. shank for drill presses and one bored to fit the arbor of radial-arm saws. I used the drill press model for this evaluation. The planer consists of a round die-cast aluminum body holding three high-speed steel cutters. The smooth rim of the bod>' extends beyond the cutters lo provide a protective barrier for safely. The cullers are mounted in a pocket under the body and are held in place by a special hex socket screw. The cutlers are shaped somewhat like a lal comma with the narrow end as the cutting tip. The cutters are easily removed for sharpening and index marks are scribed into the biwiy for easy cutler alignment. Unlike planer knives, sharpening the Safe-T-Planer cullers is a snap using a */te in. grinding wheel chucked in the drill press. An accessory kil containing Ihe grinding wheel and arbor are also available from Wagner Setup The first step toward using llie Safe-T-Planer is to check your drill press to be sure that the table is square with the arbor/quill. The recommended speed is 3000 lo 6000 rpm. Stock is hand fed: Wagner claims that a fence isn't required because the rotary action is less inclined 10 grab or kick back. While its true there's less tendency for kick back. I'd feel more comfortable using a fence for any operation. The planer culling capacity is 2J/<< in. diameter by '/■> in. deep for the drill press version. Thickness Planing As with any thickness planer, the stock must first be flattened or at least made flat enough so that the stock does not wobble under the cutters. Planing red oak and bird's-eye maple was quite easy, with litile or no tear out. The cutters do leave very slight circular ridges but these are easily removed by sanding, I tried thickness planing end-grain on a section from an ash log. The rotary cutting action was very good considering that this is a difficult operation—1 certainly wouldn't want to run end-grain through my stationary planer! A note on thickness planing with the Safe-T-Planer: there's no pressure bar or feed rollers as in a conventional planer so 14 you must be careful lo keep the work pressed against the table. Any movement or lifting off ihe table will result in a false cut or lap marks. Also, on long boards you'll need ample support (rollers or a long table) lo yield satisfactory results. Rabbets, Tenons and Coves Making rabbets and tenons in oak worked well within the cutting capacilv of the planer. Since the Sale-T-Planer will take a 'A in. cut. the work moves along quickly. Cove cuts, moldings and raised panels can be made if you have the ability to tilt the table or the drill press head. Conclusions The Safe-T-Planer has been around a long lime and clearly offers thickness planing, rabbeting and tenoning at an affordable pricc. It isn't the tool of choice for surface planing several hundred board feet of rough stock. But I like it for surfacing very thin slock, end grain and wild grain, as long as the stock isn't unwieldy. Wagner Safc-T-Planer is manufactured by G & W Tool Inc.. P.O. Box 691464. Tulsa, OK 74169-1464; tel. (918)486-2761. It is available for around $50 through established and recognized suppliers and catalogs. EJj The Woodw orker'5 Journal -T-Planer |