Woodworker's Journal 1993-17-6, страница 74

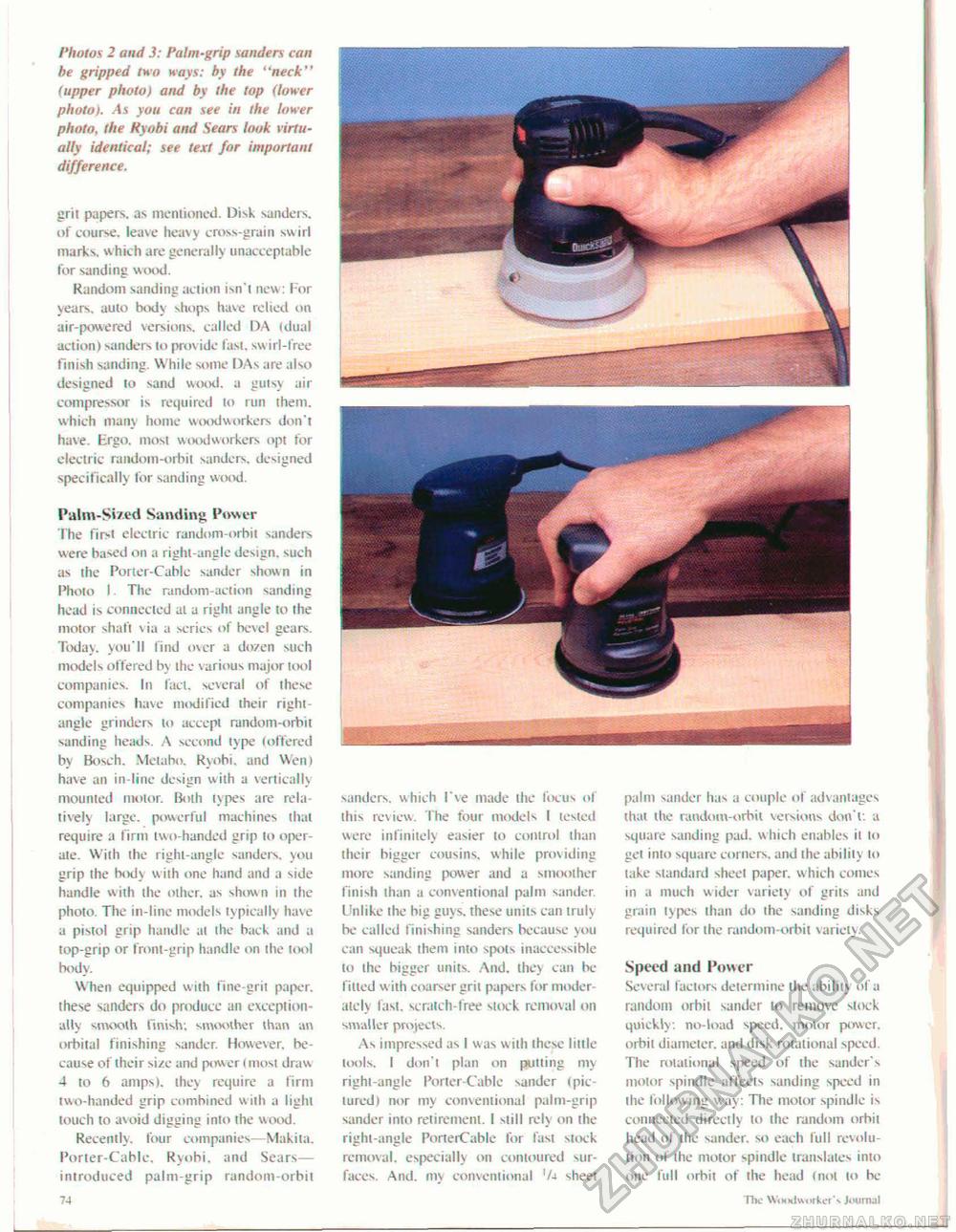

/'hotos 2 and 3: Palm-grip sanders can be gripped two ways: by the "neck" (upper photo) and by the top (lower photo). As you can see in the lower photo, the Ryobi and Sears look virtually identical; see text for important difference. grit papers, as mentioned- Disk sanders, of course, leave heavy cross-grain sw irl marks, which are generally unacceptable for sanding wood. Random sanding action isn't new: for years, auto body shops have relied on air-powered versions, called DA (dual action) sanders to provide fast, swirl-free finish sanding. While some DAs are also designed to sand wood, a gutsy air compressor is required to run them, which main home woodworkers don't have. Brgo. most woodworkers opt for electric random-orbit sanders, designed specifically for sanding wo«xl. Palm-Sized Sanding Power The first electric random-orbit sanders were based on a right-angle design, such as the Porter-Cable sander shown in Photo I. The random-action sanding head is connected ai a right angle to the motor shaft via a series of bevel gears. Today, you'll find over a dozen such modek offered by the various major tool companies. In fact, several of these companies have modified their right-angle grinders to accept random-orbit sanding heads. A second type (offered by Bosch. Melabo. Ryobi, and Wen) have an in line design with a vertically mounted motor. Both types are relatively large, powerful machines that require a firm two-handed grip to operate. With the right-angle sanders, you grip the body with one hand and a side handle with the other, as shown in the photo. The in-line models typically have a pistol grip handle at the hack and a top-grip or front-grip handle on the tool body. When equipped with fine-grit paper, these sanders do produce an exceptionally smooth finish; smoother than an orbital finishing sander. However, because of their size and power I most draw 4 to 6 amps), they require a firm two-handed grip combined with a light touch to a\oid digging into the wood. Recently, four companies—Makita. Porter-Cable, Ryobi. and Sears— introduced palm-grip random-orbit 74 sanders. which I've made the focus of this review. The tour models I tested were infinitely easier to control than their bigger cousins, while providing more sanding power and a smoother finish than a conventional palm sander. Unlike the big guys, these units can truK be called finishing sanders because you can squeak them into spots inaccessible to the bigger units. And. they can be fitted w ith coarser grit papers for moderate^ last, scratch-free slock removal on smaller projects. As impressed as 1 was with these little tools. I don't plan on pulling my righi-angle Porter Cable sunder (pictured) nor my conventional palm-grip sander into retirement. I still rely on the right-angle PorterCable for fast stock removal, especially on contoured surfaces. And. my conventional '/a sheet palm sander has a couple of advantages that the random-orbit versions don't: a square sanding pad. which enables it to get into square corners, and the ability to take standard sheet paper, which comes in a much wider variety of grits and grain types than do the sanding disks required for the random-orbit \ariety. Speed and Power Several factors determine the ability of a random orbit sander to remove stock quickly: no-load speed, motor power, orbit diameter, and disk rotational speed. The rotational speed of the Sander's motor spindle affects sanding speed in the following way: The motor spindle is connected directly lo the random orbii head of the sander. so each full revolution of the motor spindle translates into one full orbit of the head (not to be The WiKidwiirker's Jimin.il |