Woodworker's Journal 2001-25-1, страница 80

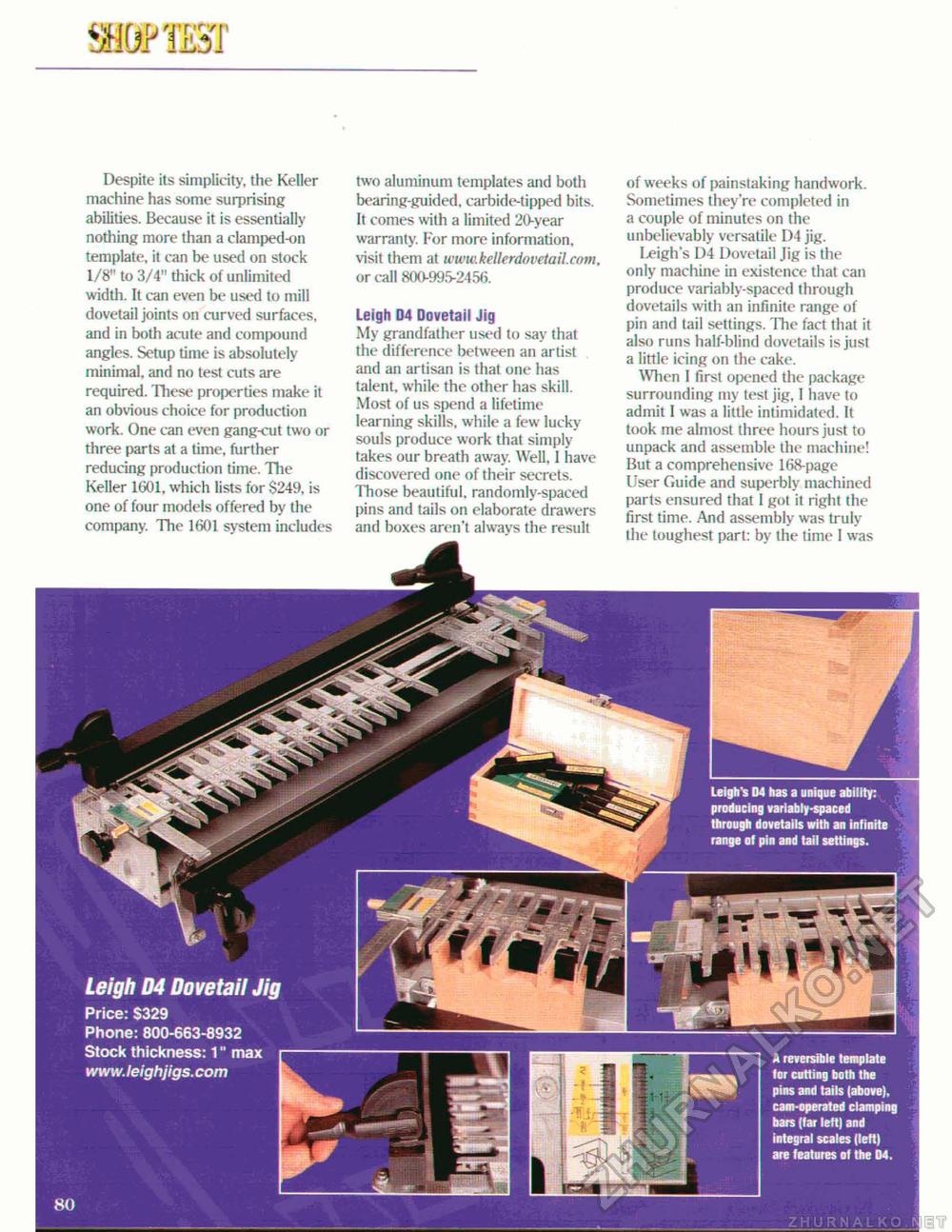

MtflEST Leigh D4 Dovetail Jig Price: S329 Phone: 800-663-8932 Stock thickness: 1" max www. leighjigs. com Leigh's D4 has a unique ability: producing variably-spaced through dovetails with an intinite range of pin and tail settings. A reversible template tor cutting both the pins and tails (above), cam-operated clamping bars (far left) and integral scales (left) are features of the D4. Despite its simplicity, the Keller machine has some surprising abilities. Because it is essentially nothing more than a clamped-on template, it can be used on stock 1/8" to 3/4" thick of unlimited width. It can even be used to mill dovetail joints on curved surfaces, and in both acute and compound angles. Setup time is absolutely minimal, and no test cuts are required. These properties make it an obvious choice for production work. One can even gang-cut two or three parts at a time, further reducing production time. The Keller 1601, which lists for $249. is one of four models offered by the company. The 1601 system includes two aluminum templates and both bearing-guided, carbide-tipped bits. It comes with a limited 20-year warranty. For more information, visit them at www.kellerdovetail.com. or call 800-995-2456. Leigh D4 Dovetail Jig My grandfather used to say that the difference between an artist and an artisan is that one has talent, while the other has skill. Most of us spend a lifetime learning skills, while a few lucky souls produce work that simply takes our breath away. Well, 1 have discovered one of their secrets. Those beautiful, randomly-spaced pins and tails on elaborate drawers and boxes aren't always the result of weeks of painstaking handwork. Sometimes they're completed in a couple of minutes on the unbelievably versatile D4 jig. leigh's D4 Dovetail Jig is the only machine in existence that can produce variably-spaced through dovetails with an infinite range of pin and tail settings. The fact that it also runs half-blind dovetails is just a little icing on the cake. When I first opened the package surrounding my test jig, I have to admit I was a little intimidated. It took me almost three hours just to unpack and assemble the machine! But a comprehensive 168-page User Guide and superbly machined parts ensured that 1 got it right the first time. And assembly was truly the toughest part: by the time I was |