Woodworker's Journal 2001-25-2, страница 66

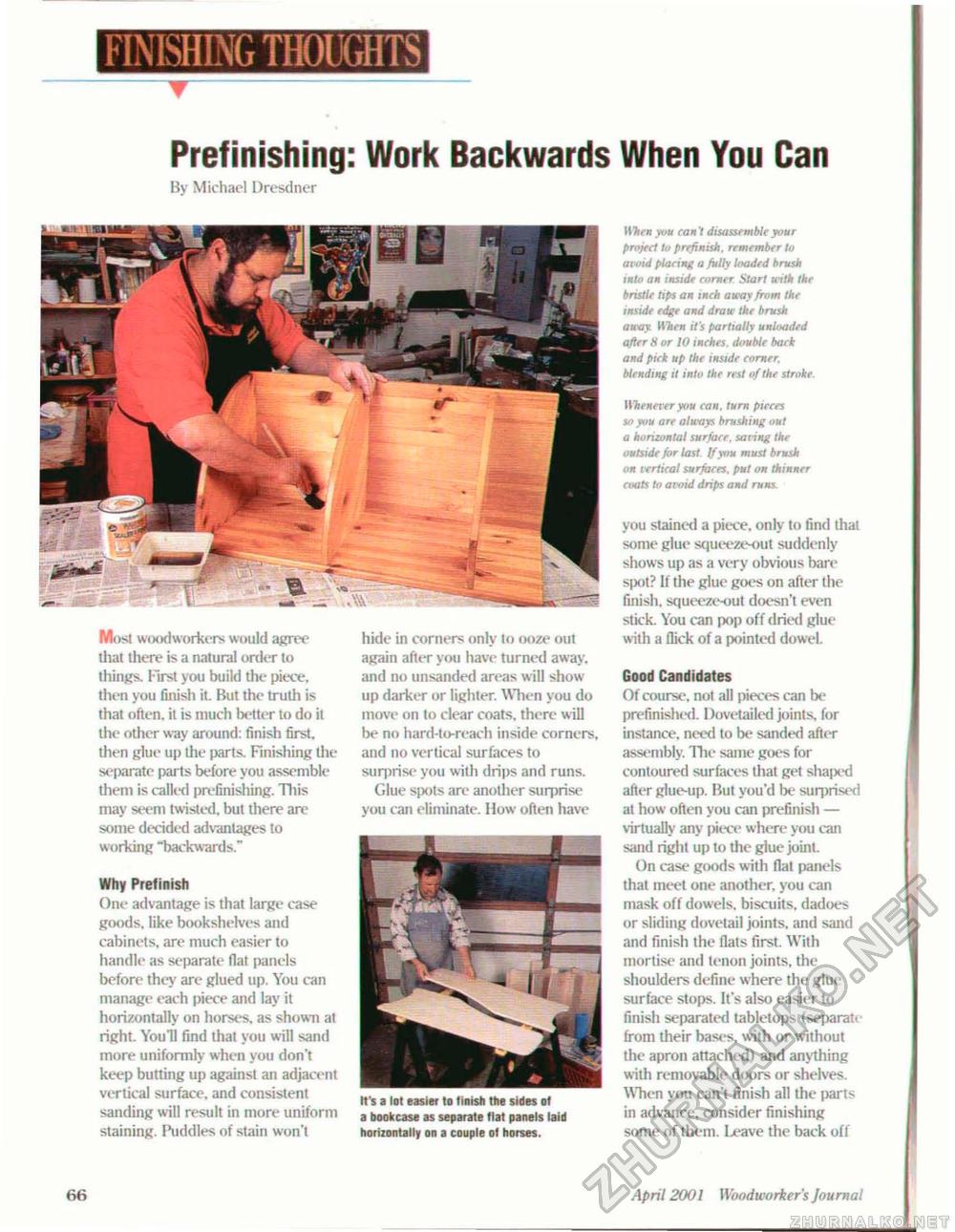

FINISHING THOUGHTS ▼ Prefinishing: Work Backwards By Michael Dresdner Most woodworkers would agree that there is a natural order to things. First you build the piece, then you finish it. But the truth is that often, it is much better to do it the other way around: finish first, then glue up the parts. Finishing the separate parts before you assemble them is called prefinishing. This may seem twisted, but there are some decided advantages to working "backwards." Why Prefinish One advantage is that large case goods, like bookshelves and cabinets, are much easier to handle as separate flat panels before they are glued up. You can manage each piece and lay it horizontally on horses, as shown at right. You'll find that you will sand more uniformly when you don't keep butting up against an adjacent vertical surface, and consistent sanding will result in more uniform staining. Puddles of stain won't hide in corners only to ooze out again after you have turned away, and no unsanded areas will show up darker or lighter. When you do move on to clear coats, there will be no hard-to-reach inside corners, and no vertical surfaces to surprise you with drips and runs. Glue spots are another surprise you can eliminate. How often have It's a lot easier to finish the sides ot a bookcase as separate flat panels laid horizontally on a couple of horses. When You Can When you can't disassembleyour project to prefinish, remember to amid placing a fully loaded brush into an inside corner Start with the bnstle tips an inch away from the inside edge and draw the brush away When it's partially unloaded after ti or 10 inches, double bark and pick up the inside corner, blending it into the rest of the stroke. Whenever you can. turn pieces so you art always brushing nut a horizontal surface, saring the outside for last If you must brush on vertical surfaces, put on thinner coats to avoid drips and runs you stained a piece, only to find that some glue squeezeout suddenly shows up as a very obvious bare spot? It the glue goes on after the finish, squeeze-out doesn't even stick. You can pop off dried glue with a flick of a pointed dowel. Good Candidates Of course, not all pieces can be prefinished. Dovetailed joints, for instance, need to be sanded after assembly. The same goes for contoured surfaces that get shajx-d after glue-up. But you'd be surprised at how often you can prefinish — virtually any piece where you can sand right up to the glue joint. On case goods with fiat panels that meet one another, you can mask off dowels, biscuits, dadoes or sliding dovetail joints, and sand and finish the flats first. With mortise and tenon joints, the shoulders define where the glue surface stops. It's also easier to finish separated tabletops {separate from their bases, with or without the apron attached) and anything with removable doors or shelves. When you can't finish all the pan-in advance, consider finishing some of them. h*ave the back off 66 April 2001 Woodworker 's Journal |