Woodworker's Journal 2001-25-2, страница 78

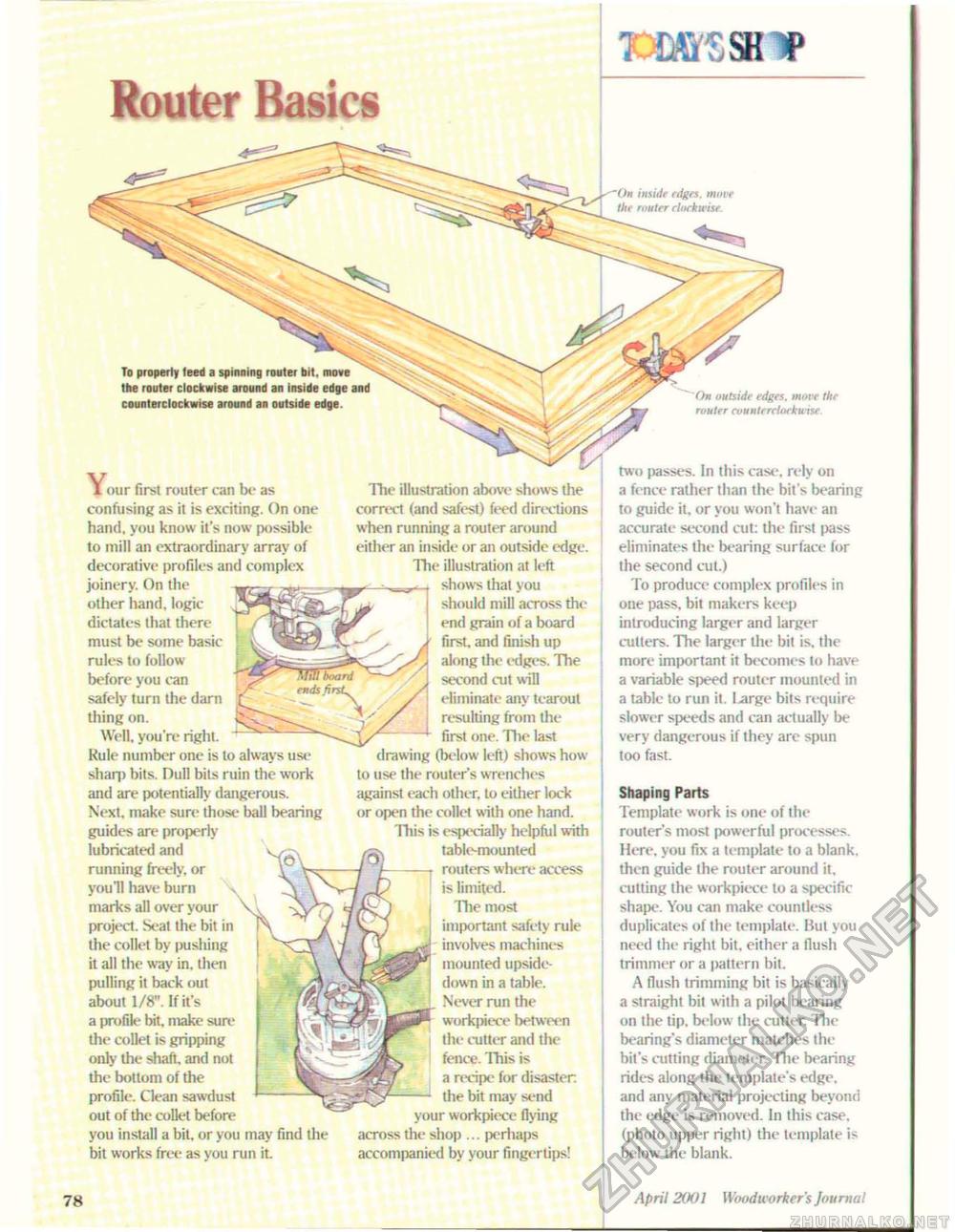

TCMTCSH iP Router Basics inside edges, mutte Hie router clockwise. To properly feed a spinning router bit, move the router clockwise around an inside edge and counterclockwise around an outside edge. outside edges, more the router counlerrloekwise. two passes. In this case, rely on a fence rather than the bit's bearing to guide it. or you won't have an accurate second cut: the first pass eliminates the bearing surface for the second cut.) To produce complex profiles in one pass, bit makers keep introducing larger and larger cutlers. The larger the bit is, the more important it becomes to have a variable speed router moutiled in a table to run it. large bits require slower speeds and can actually l>e very dangerous if they are spun loo fast. Shaping Parts Template work is one of the router's most powerful processes. Here, you fix a template to a blank, then guide the router around it, cutting the workpiece to a specific shape. You can make countless duplicates of the template. But you need the right bil. either a llush trimmer or a pattern bit. A flush trimming bit is basicalh a straight bit with a pilot bearing on the tip. below ihe cutler. The bearing's diameter matches the bit's cutting diameter. Hie bearing rides along the template's edge, and any material projecting beyond the edge is removed. In this case, (photo upper right) the template is below the blank. I our first router can be as confusing as it is exciting. On one hand, you know it's now possible to mill an extraordinary array of decorative profiles and complex joinery. On the other hand, logic dictates thai there must be some basic rules to follow before you can safely turn the dam thing on. Welt you're right. Rule number one is lo always use sharp bits. Dull bils ruin the work and are potentially dangerous. Next, make sure those ball bearing guides are properly lubricated and running freely, or youll have burn marks all over your project Seal the bit in the collet by pushing it all the way in. then pulling it back out about 1/8". If it's a profile bit. make sure the collet is gripping only the shaft, and not the bottom of the profile. Clean sawdust out of the collet before you install a bit, or you may find the bit works free as you run it. The illustration above shows the correct (and safest) feed directions when running a router around either an inside or an outside edge. The illustration at left shows thai you should mill across the end grain of a board first, and finish up along the edges. The second cut will eliminate any tearoul resulting from the first one. The last drawing (below left) shows how-to use the router's wrenches against each other, lo either lock or open the collet with one hand. This is especially helpful with table-mounted routers where access is limited. The most important safety rule involves machines mounted upside-down in a table. Never run the workpiece between the cutler and the fence. This is a recipe for disaster the bit may send your workpiece (lying across the shop ... perhaps accompanied by your fingertips! 78 April 2001 Woodworker 's Journal |