Woodworker's Journal 2004 Spring, страница 26

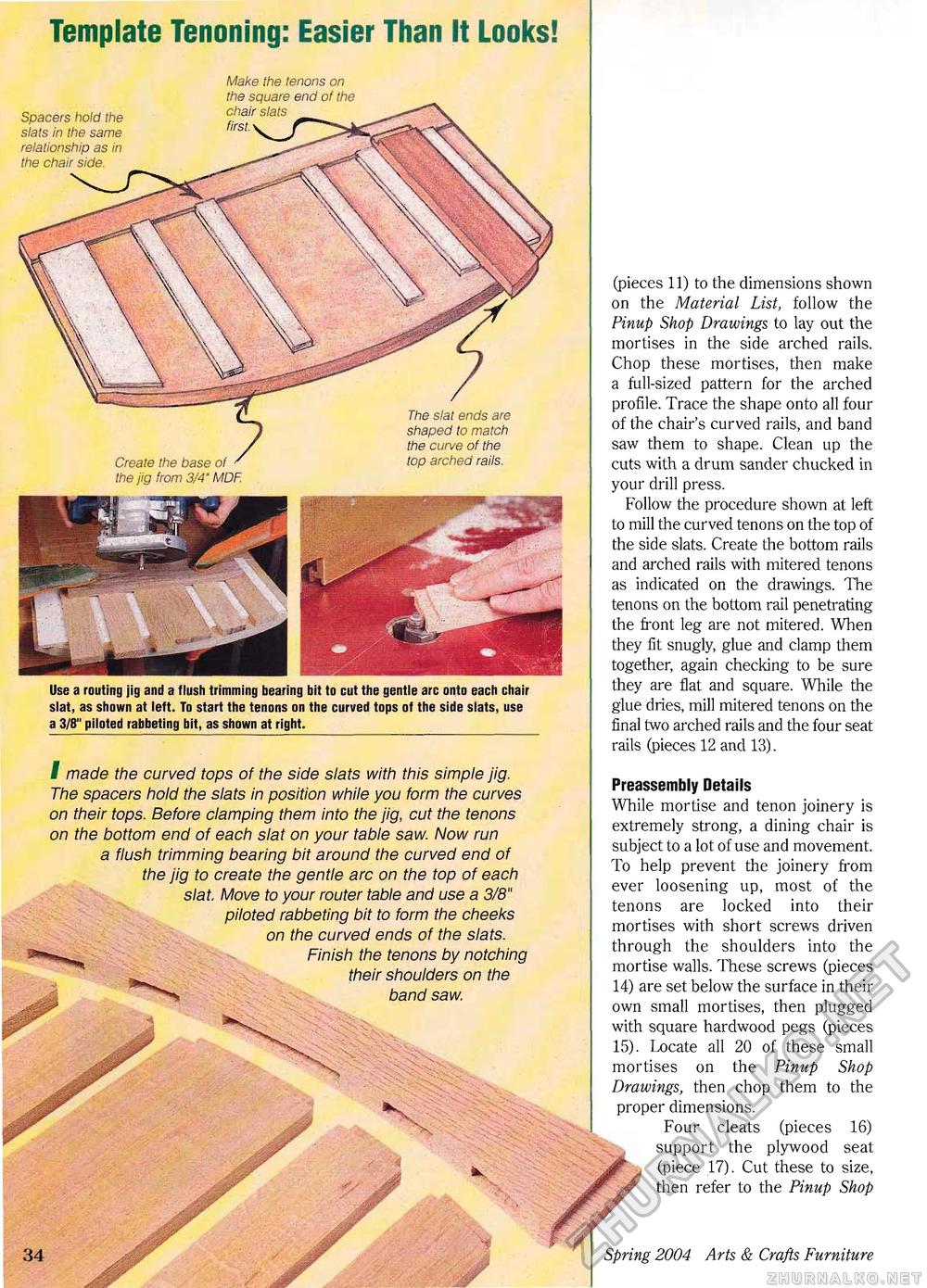

Template Tenoning: Easier Than It Looks!Spacers hold the slats in the same relationship as in the chair side. Make the tenons on the square end of the chair slats first. The slat ends are shaped to match the curve of the top arched rails. Create the base of the jig from 3/4" MDF. Use a routing jig and a flush trimming bearing bit to cut the gentle arc onto each chair slat, as shown at left. To start the tenons on the curved tops of the side slats, use a 3/8" piloted rabbeting bit, as shown at right. (pieces 11) to the dimensions shown on the Material List, follow the Pinup Shop Drawings to lay out the mortises in the side arched rails. Chop these mortises, then make a full-sized pattern for the arched profile. Trace the shape onto all four of the chair's curved rails, and band saw them to shape. Clean up the cuts with a drum sander chucked in your drill press. Follow the procedure shown at left to mill the curved tenons on the top of the side slats. Create the bottom rails and arched rails with mitered tenons as indicated on the drawings. The tenons on the bottom rail penetrating the front leg are not mitered. When they fit snugly, glue and clamp them together, again checking to be sure they are flat and square. While the glue dries, mill mitered tenons on the final two arched rails and the four seat rails (pieces 12 and 13). Preassembly Details While mortise and tenon joinery is extremely strong, a dining chair is subject to a lot of use and movement. To help prevent the joinery from ever loosening up, most of the tenons are locked into their mortises with short screws driven through the shoulders into the mortise walls. These screws (pieces 14) are set below the surface in their own small mortises, then plugged with square hardwood pegs (pieces 15). Locate all 20 of these small mortises on the Pinup Shop Drawings, then chop them to the proper dimensions. Four cleats (pieces 16) support the plywood seat (piece 17). Cut these to size, then refer to the Pinup Shop Spring 2004 Arts & Crafts Furniture I made the curved tops of the side slats with this simple jig. The spacers hold the slats in position while you form the curves on their tops. Before clamping them into the jig, cut the tenons on the bottom end of each slat on your table saw. Now run a flush trimming bearing bit around the curved end of the jig to create the gentle arc on the top of each slat. Move to your router table and use a 3/8" piloted rabbeting bit to form the cheeks on the curved ends of the slats. Finish the tenons by notching their shoulders on the band saw. |