Woodworker's Journal 2004 Spring, страница 27

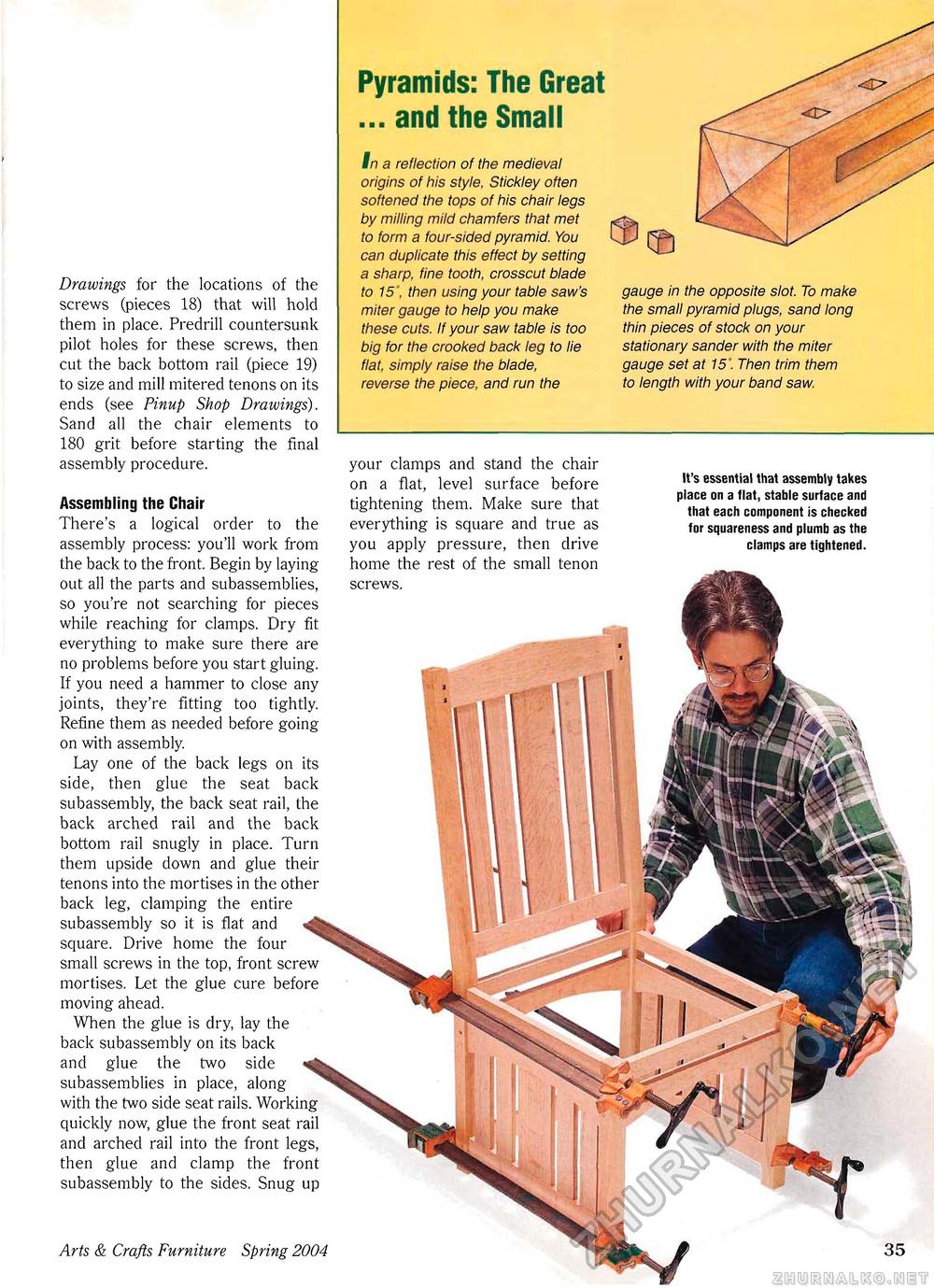

Pyramids: The Great ... and the SmallIn a reflection of the medieval origins of his style, Stickley often softened the tops of his chair legs by milling mild chamfers that met to form a four-sided pyramid. You can duplicate this effect by setting a sharp, fine tooth, crosscut blade to 15 . then using your table saw's miter gauge to help you make these cuts. If your saw table is too big for the crooked back leg to lie flat, simply raise the blade, reverse the piece, and run the gauge in the opposite slot. To make the small pyramid plugs, sand long thin pieces of stock on your stationary sander with the miter gauge set at 15". Then trim them to length with your band saw. Arts & Crafts Furniture Spring 2004 17 Drawings for the locations of the screws (pieces 18) that will hold them in place. Predrill countersunk pilot holes for these screws, then cut the back bottom rail (piece 19) to size and mill mitered tenons on its ends (see Pinup Shop Drawings). Sand all the chair elements to 180 grit before starting the final assembly procedure. Assembling the Chair There's a logical order to the assembly process: you'll work from the back to the front. Begin by laying out all the parts and subassemblies, so you're not searching for pieces while reaching for clamps. Dry fit everything to make sure there are no problems before you start gluing. If you need a hammer to close any joints, they're fitting too tightly. Refine them as needed before going on with assembly. Lay one of the back legs on its side, then glue the seat back subassembly, the back seat rail, the back arched rail and the back bottom rail snugly in place. Turn them upside down and glue their tenons into the mortises in the other back leg, clamping the entire subassembly so it is flat and square. Drive home the four small screws in the top, front screw mortises. Let the glue cure before moving ahead. When the glue is dry, lay the back subassembly on its back and glue the two side subassemblies in place, along with the two side seat rails. Working quickly now, glue the front seat rail and arched rail into the front legs, then glue and clamp the front subassembly to the sides. Snug up your clamps and stand the chair on a flat, level surface before tightening them. Make sure that everything is square and true as you apply pressure, then drive home the rest of the small tenon screws. It's essential that assembly takes place on a flat, stable surface and that each component is checked for squareness and plumb as the clamps are tightened. |