Woodworker's Journal 2004 Spring, страница 45

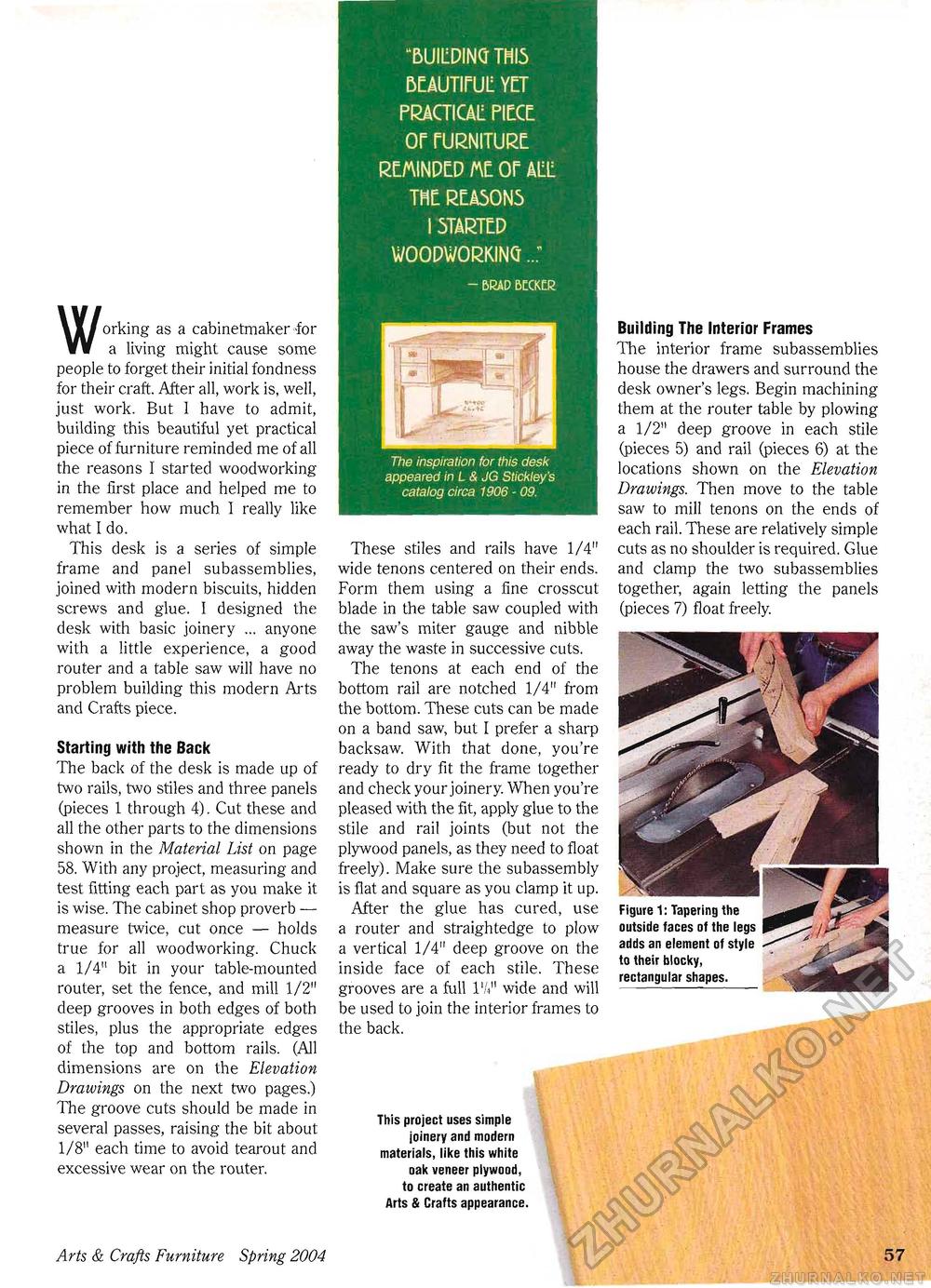

Working as a cabinetmaker for a living might cause some people to forget their initial fondness for their craft. After all, work is, well, just work. But I have to admit, building this beautiful yet practical piece of furniture reminded me of all the reasons I started woodworking in the first place and helped me to remember how much I really like what I do. This desk is a series of simple frame and panel subassemblies, joined with modern biscuits, hidden screws and glue. I designed the desk with basic joinery ... anyone with a little experience, a good router and a table saw will have no problem building this modern Arts and Crafts piece. Starting with the Back The back of the desk is made up of two rails, two stiles and three panels (pieces 1 through 4). Cut these and all the other parts to the dimensions shown in the Material List on page 58. With any project, measuring and test fitting each part as you make it is wise. The cabinet shop proverb — measure twice, cut once — holds true for all woodworking. Chuck a 1/4" bit in your table-mounted router, set the fence, and mill 1/2" deep grooves in both edges of both stiles, plus the appropriate edges of the top and bottom rails. (All dimensions are on the Elevation Drawings on the next two pages.) The groove cuts should be made in several passes, raising the bit about 1/8" each time to avoid tearout and excessive wear on the router. "BUILDING THI5 BEAUTIFUL YET PRACtlOU PIECE or EURNITURE REMINDED ftE Of Will THE REA50N5 I STARTED WOODWORKING..." - BRAD BECKER The inspiration for this desk appeared in L&JG Stickley's catalog circa 1906 - 09. These stiles and rails have 1/4" wide tenons centered on their ends. Form them using a fine crosscut blade in the table saw coupled with the saw's miter gauge and nibble away the waste in successive cuts. The tenons at each end of the bottom rail are notched 1/4" from the bottom. These cuts can be made on a band saw, but I prefer a sharp backsaw. With that done, you're ready to dry fit the frame together and check your joinery. When you're pleased with the fit, apply glue to the stile and rail joints (but not the plywood panels, as they need to float freely). Make sure the subassembly is flat and square as you clamp it up. After the glue has cured, use a router and straightedge to plow a vertical 1/4" deep groove on the inside face of each stile. These grooves are a full 1\V' wide and will be used to join the interior frames to the back. Building The Interior Frames The interior frame subassemblies house the drawers and surround the desk owner's legs. Begin machining them at the router table by plowing a 1/2" deep groove in each stile (pieces 5) and rail (pieces 6) at the locations shown on the Elevation Drawings. Then move to the table saw to mill tenons on the ends of each rail. These are relatively simple cuts as no shoulder is required. Glue and clamp the two subassemblies together, again letting the panels (pieces 7) float freely. Figure 1: Tapering the outside faces of the legs adds an element of style to their blocky, rectangular shapes. This project uses simple joinery and modern materials, like this white oak veneer plywood, to create an authentic Arts & Crafts appearance. Arts & Crafts Furniture Spring 2004 17 |