Woodworker's Journal 2004 Spring, страница 49

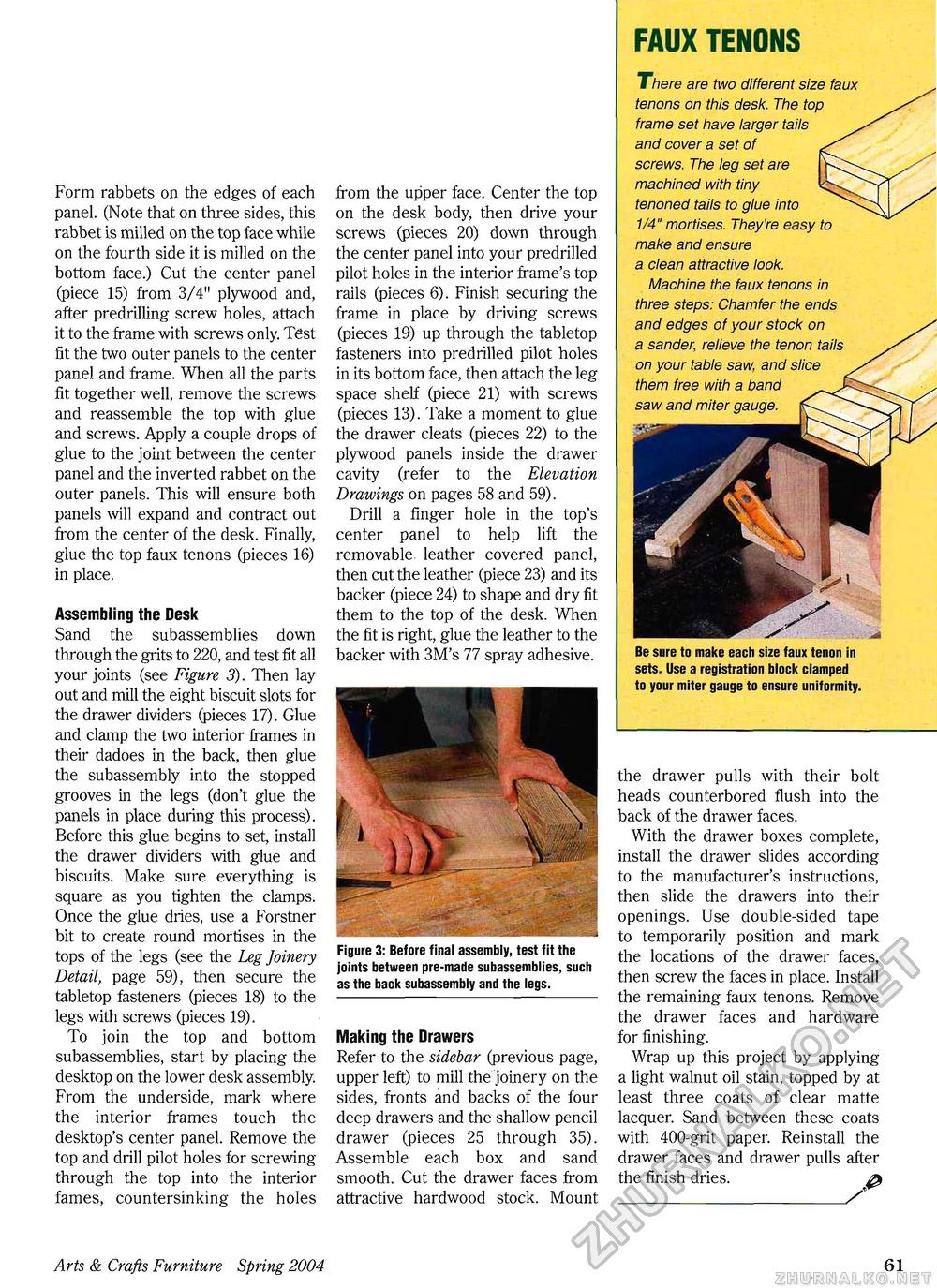

FAUX TENONS Form rabbets on the edges of each panel. (Note that on three sides, this rabbet is milled on the top face while on the fourth side it is milled on the bottom face.) Cut the center panel (piece 15) from 3/4" plywood and, after predrilling screw holes, attach it to the frame with screws only. Test fit the two outer panels to the center panel and frame. When all the parts fit together well, remove the screws and reassemble the top with glue and screws. Apply a couple drops of glue to the joint between the center panel and the inverted rabbet on the outer panels. This will ensure both panels will expand and contract out from the center of the desk. Finally, glue the top faux tenons (pieces 16) in place. Assembling the Desk Sand the subassemblies down through the grits to 220, and test fit all your joints (see Figure 3). Then lay out and mill the eight biscuit slots for the drawer dividers (pieces 17). Glue and clamp the two interior frames in their dadoes in the back, then glue the subassembly into the stopped grooves in the legs (don't glue the panels in place during this process). Before this glue begins to set, install the drawer dividers with glue and biscuits. Make sure everything is square as you tighten the clamps. Once the glue dries, use a Forstner bit to create round mortises in the tops of the legs (see the Leg Joinery Detail, page 59), then secure the tabletop fasteners (pieces 18) to the legs with screws (pieces 19). To join the top and bottom subassemblies, start by placing the desktop on the lower desk assembly. From the underside, mark where the interior frames touch the desktop's center panel. Remove the top and drill pilot holes for screwing through the top into the interior fames, countersinking the holes from the upper face. Center the top on the desk body, then drive your screws (pieces 20) down through the center panel into your predrilled pilot holes in the interior frame's top rails (pieces 6). Finish securing the frame in place by driving screws (pieces 19) up through the tabletop fasteners into predrilled pilot holes in its bottom face, then attach the leg space shelf (piece 21) with screws (pieces 13). Take a moment to glue the drawer cleats (pieces 22) to the plywood panels inside the drawer cavity (refer to the Elevation Drawings on pages 58 and 59). Drill a finger hole in the top's center panel to help lift the removable leather covered panel, then cut the leather (piece 23) and its backer (piece 24) to shape and dry fit them to the top of the desk. When the fit is right, glue the leather to the backer with 3M's 77 spray adhesive. Figure 3: Before final assembly, test fit the joints between pre-made subassemblies, such as the back subassembly and the legs. Making the Drawers Refer to the sidebar (previous page, upper left) to mill the joinery on the sides, fronts and backs of the four deep drawers and the shallow pencil drawer (pieces 25 through 35). Assemble each box and sand smooth. Cut the drawer faces from attractive hardwood stock. Mount the drawer pulls with their bolt heads counterbored flush into the back of the drawer faces. With the drawer boxes complete, install the drawer slides according to the manufacturer's instructions, then slide the drawers into their openings. Use double-sided tape to temporarily position and mark the locations of the drawer faces, then screw the faces in place. Install the remaining faux tenons. Remove the drawer faces and hardware for finishing. Wrap up this project by applying a light walnut oil stain, topped by at least three coats of clear matte lacquer. Sand between these coats with 400-grit paper. Reinstall the drawer faces and drawer pulls after the finish dries. & _/ There are two different size faux tenons on this desk. The top frame set have larger tails and cover a set of screws. The leg set are machined with tiny tenoned tails to glue into 1/4" mortises. They're easy to make and ensure a clean attractive look. Machine the faux tenons in three steps: Chamfer the ends and edges of your stock on a sander, relieve the tenon tails on your table saw, and slice them free with a band saw and miter gauge. Be sure to make each size faux tenon in sets. Use a registration block clamped to your miter gauge to ensure uniformity. Arts & Crafts Furniture Spring 2004 17 |