Woodworker's Journal 2004 Spring, страница 54

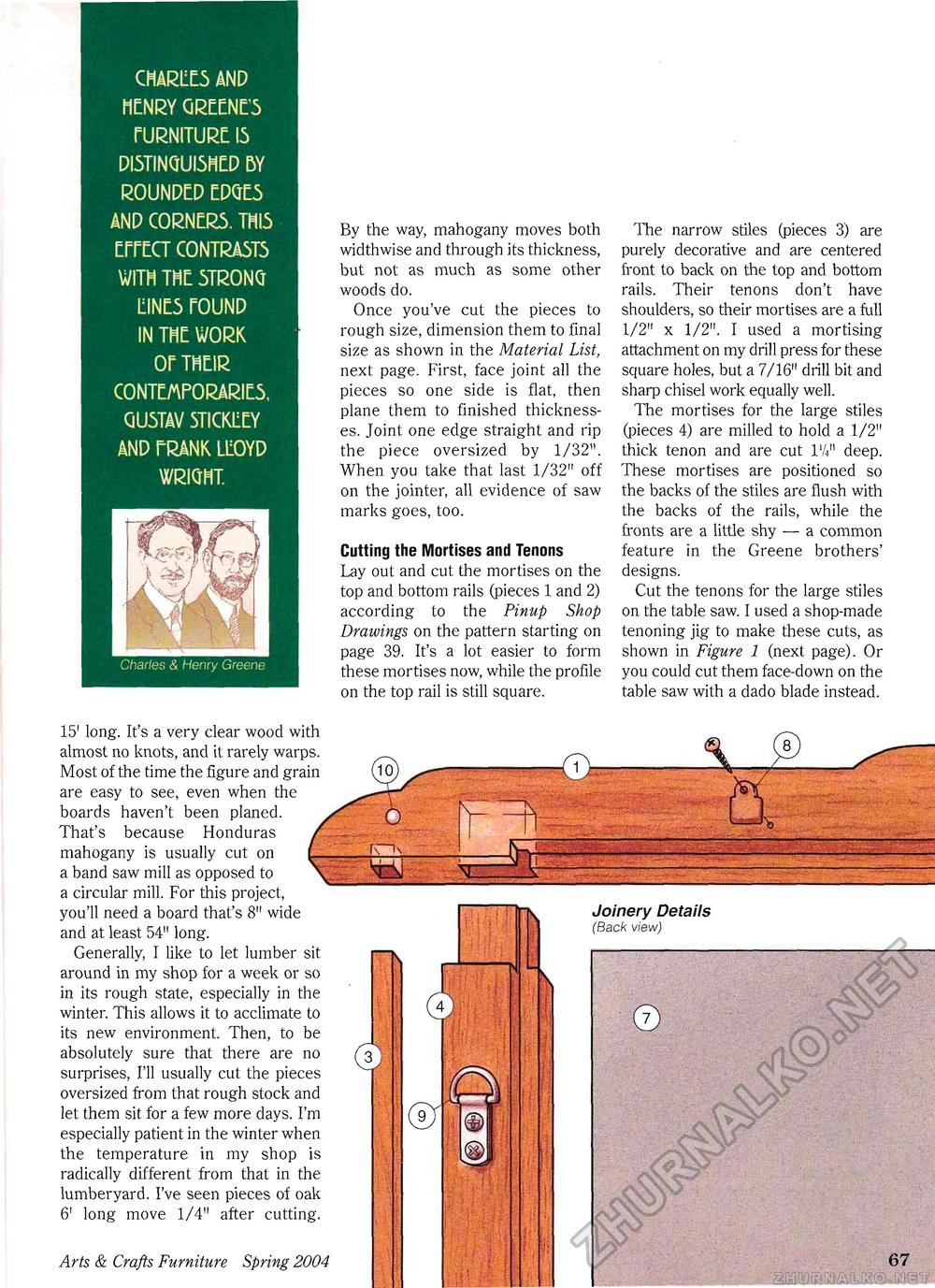

CMARLE5 AND HENRY GREENE'S EURNITURE 15 DISTINGUISHED BY ROUNDED EDGES AND CORNERS. THI5 EEEECT CONTRASTS WITH THE STRONG LINES EOUND IN THE WORK Or THEIR CONTEMPORARIES, QUSTAV 5TICK11EY AND ERANK LLOYD WRIGHT Charles & Henry Greene By the way, mahogany moves both widthwise and through its thickness, but not as much as some other woods do. Once you've cut the pieces to rough size, dimension them to final size as shown in the Material List, next page. First, face joint all the pieces so one side is flat, then plane them to finished thicknesses. Joint one edge straight and rip the piece oversized by 1/32". When you take that last 1/32" off on the jointer, all evidence of saw marks goes, too. Cutting the Mortises and Tenons Lay out and cut the mortises on the top and bottom rails (pieces 1 and 2) according to the Pinup Shop Drawings on the pattern starting on page 39. It's a lot easier to form these mortises now, while the profile on the top rail is still square. The narrow stiles (pieces 3) are purely decorative and are centered front to back on the top and bottom rails. Their tenons don't have shoulders, so their mortises are a full 1/2" x 1/2". I used a mortising attachment on my drill press for these square holes, but a 7/16" drill bit and sharp chisel work equally well. The mortises for the large stiles (pieces 4) are milled to hold a 1/2" thick tenon and are cut lVi" deep. These mortises are positioned so the backs of the stiles are flush with the backs of the rails, while the fronts are a little shy — a common feature in the Greene brothers' designs. Cut the tenons for the large stiles on the table saw. I used a shop-made tenoning jig to make these cuts, as shown in Figure 1 (next page). Or you could cut them face-down on the table saw with a dado blade instead. Joinery Details (Back view) 15' long. It's a very clear wood with almost no knots, and it rarely warps. Most of the time the figure and grain are easy to see, even when the boards haven't been planed. That's because Honduras mahogany is usually cut on a band saw mill as opposed to a circular mill. For this project, you'll need a board that's 8" wide and at least 54" long. Generally, I like to let lumber sit around in my shop for a week or so in its rough state, especially in the winter. This allows it to acclimate to its new environment. Then, to be absolutely sure that there are no surprises, I'll usually cut the pieces oversized from that rough stock and let them sit for a few more days. I'm especially patient in the winter when the temperature in my shop is radically different from that in the lumberyard. I've seen pieces of oak 6' long move 1/4" after cutting. Arts & Crafts Furniture Spring 2004 17 |