Woodworker's Journal 2004-28-4, страница 21

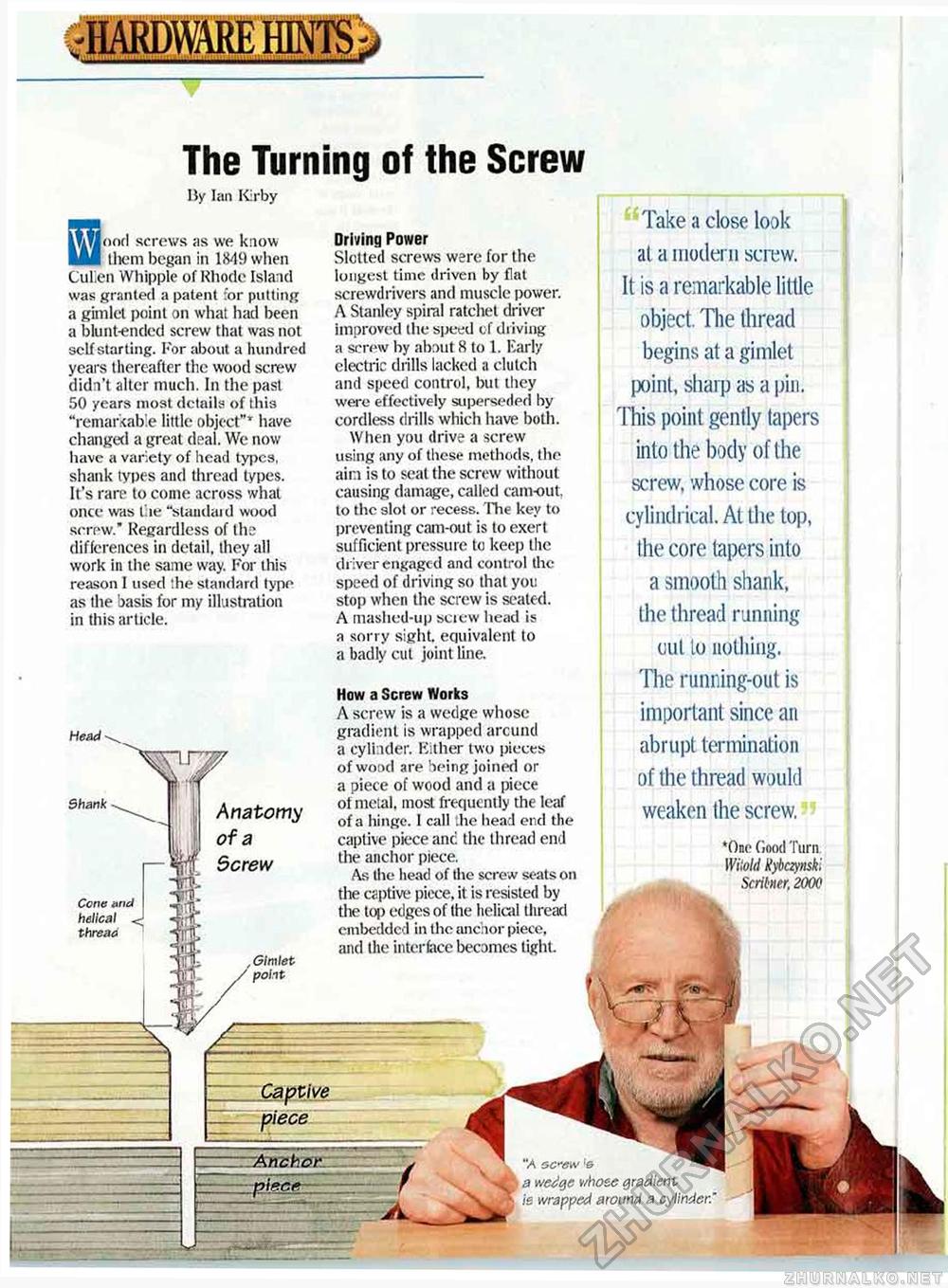

MMRE HINTS The Turning nf the Screw By Ian Kirby loorl screws as we know them began in 1849 when Culien Whipple of Rhode Island was granted a patent for putting a gimlet point on what had been a blunt-ended screw that was not self starting. For about a hundred years thereafter the wood screw didn't alter much. In the past 50 years most details of this "remarkable little object"' have changed a great deal. We now have a variety of head types, shank types and thread types. It's rare to come across what once was t ie "standaid wood screw." Regardless of the differences in detail, they all work in the same way. For this reason I used :he standard typo as the basis for my illustration in this article. Head 5hank Anatomy of a Screw Cone and helical < thread Driving Power Slotted screws were for the longest time driven by flat screwdrivers and muscle power. A Stanley spiral ratchet driver improved the speed of driving a screw by ab.Mit 8 to 1. Early electric drills lacked a clutch and speed control, but they were effectively superseded by cordless drills which have both. When you drive a screw using any of these methods, the aim is to seat the screw without causing damage, called cam-out. to the slot or recess. The key to preventing cam-out is to exert sufficient pressure to keep the driver engaged and control the speed of driving so that you stop when the screw is seated. A mashed-up screw head is a sorry sight, equivalent to a badly cut joint line. How a Screw Works A screw is a wedge whose gradient is wrapped arcund a cylinder. Either two pieces of wood are being joined or a piece of wood and a piece ot metal, most frequently the leaf of a hinge. I call he head end the captive piece anc the thread end the anchor piece. As the head of the screw seats on the captive piece, it is resisted by Take a close look at a modern screw. It is a remarkable little object. The thread begins at a gimlet point, sharp as a pin. This point gently tapers into the body of the screw, whose core is cylindrical. At the top, the core tapers into a smooth shank, the thread running cut to nothing. The running-out is important since an abrupt termination of the thread would weaken the screw. *0ne Good Turn Wiiold Hybczynski |