Woodworker's Journal 2004-28-4, страница 49

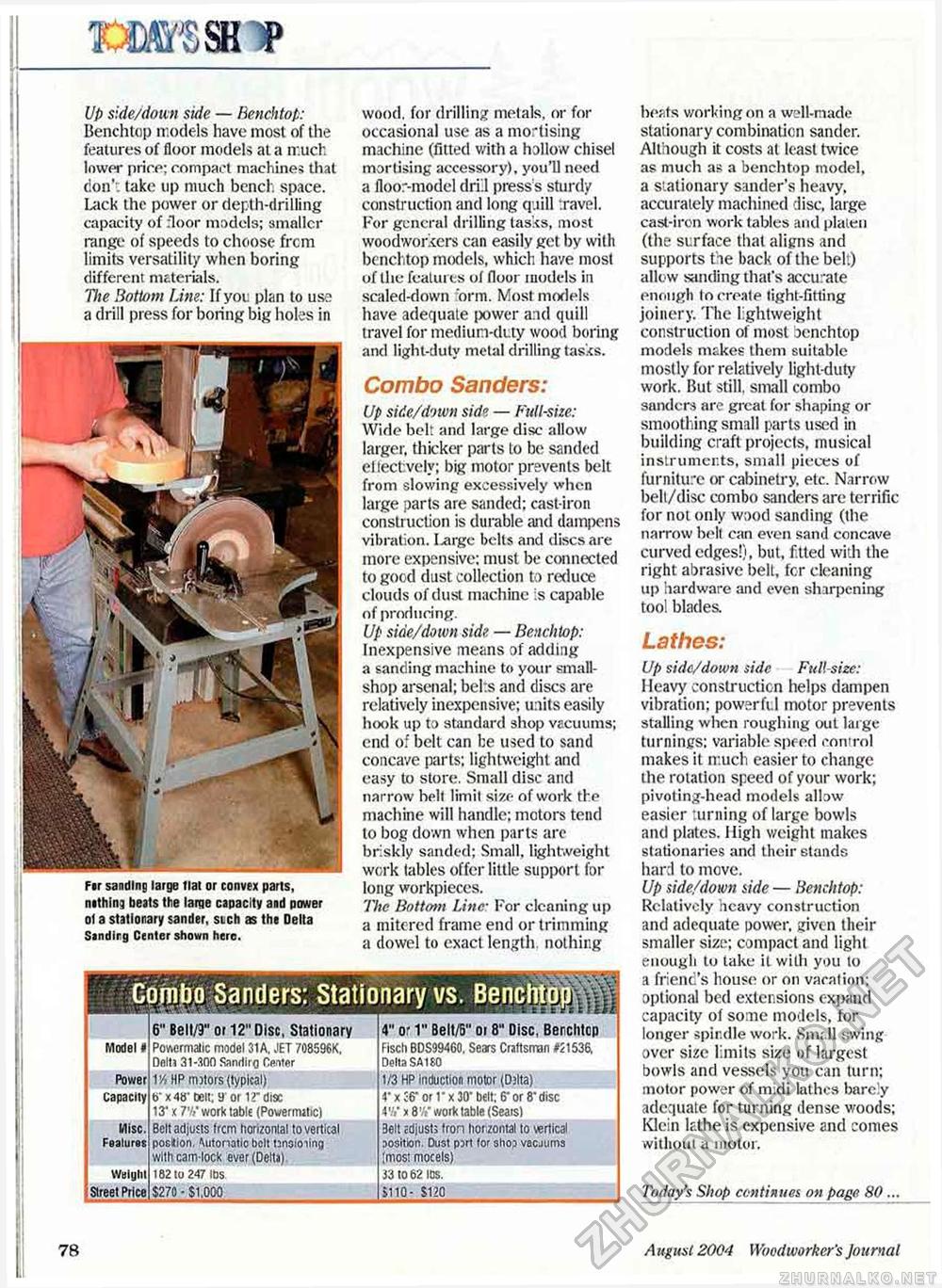

OMSH P Up side/do tut side — Benchtop: Benchtop models have most of the features of floor models at a much lower price; compact machines that don': take up much bench space. Lack the power or depth-drilling capacity of floor models; smaller range of speeds to choose frcm limits versatility when boring different materials. Vie Bottom Line: If you plan to use a drill press for boring big holes in Far sanding large flat or convex parts, nithing beats the large capacity and power ot a stationary sander, sich as the Delta Sanding Center shown here. wood, for drilling metals, or for occasional use as a mortising machine (fitted with a hollow chisel mortising accessory), you'll need a floor-model drill press's sturdy construction and long quill .ravel. For general drilling tasks, most woodworkers can easily get by with benchtop models, which have most of the features uf floor models in scaled-down "orm. Most models have adequate power and quill travel for medium-duty wood boring and light-duty metal drilling tasks. Combo Sanders: Up side/down sid°. — Full-size: Wide belt and large disc allow larger, thicker parts to be sanded effectively; big motor prevents belt from slowing excessively when large parts are sanded; cast-iron construction is durable and dampens vibration. Ixirgc belts and discs are more expensive: must be connected to good dust collection to reduce clouds of dust machine is capable of producing. Up side/down side — Benchtop: Inexpensive means of adding a sanding machine to your small-shop arsenal; belts and discs are relatively inexpensive; units easily hook up to standard shop vacuums; end of belt can be used to sand concave parts; lightweight and easy to store. Small disc and narrow hell limit size of work the machine will handle; motors tend lo bog down when parts are briskly sanded; Small, lightweight work tables offer little support for long workpieces. The Bottom Line For cleaning up a mitercd frame end or trimming a dowel to exact length, nothing

heats working on a well-made stationary combination sander. Although it costs at least twice as much as a benchtop model, a stationary sander's heavy, accurately machined disc, large cast-iron work tables and platen (the surface that aligns and supports the back of the belt) allow sanding that's accurate enough to create tight-fitting joinery. The lightweight construction of most bcnchtop models makes them suitable mostly for relatively light-duty work. But still, small combo sandcrs are great for shaping or smoothing small parts used in building craft projects, musical instruments, small pieces of furniture or cabinetry, etc. Narrow belt/disc combo sanders are terrific for not only wood sanding (the narrow belt can even sand concave curved edges!), but, f.tted with the right abrasive belt, for cleaning up hardware and even sharpening too! blades. Lathes: Up side/down side Full-size: Heavy construction helps dampen vibration; powerful motor prevents stalling when roughing out large turnings; variable speed control makes it much easier to change the rotation speed of your work; pivoting-head models allow easier turning of large bowls and plates. High weight makes stationaries and their stands hard to move. Up side/down side — Benchtop: Relatively heavy construction and adequate power, given their smaller size; compact and light enough to take it with you to a friend's house* or on vacation; optional bed extensions expand capacity of some models, for longer spindle work. Smr.ll swing over size limits size of largest bowls and vessels you can turn; motor power of midi lathes barely adequate for turning dense woods; Klein lathe is expensive and comes without a motor. Today's Shop continues on page HO ... 49 August 2004 Woodworker's Journal |

|||||||||||||||||||||