Woodworker's Journal 2006-30-2, страница 40

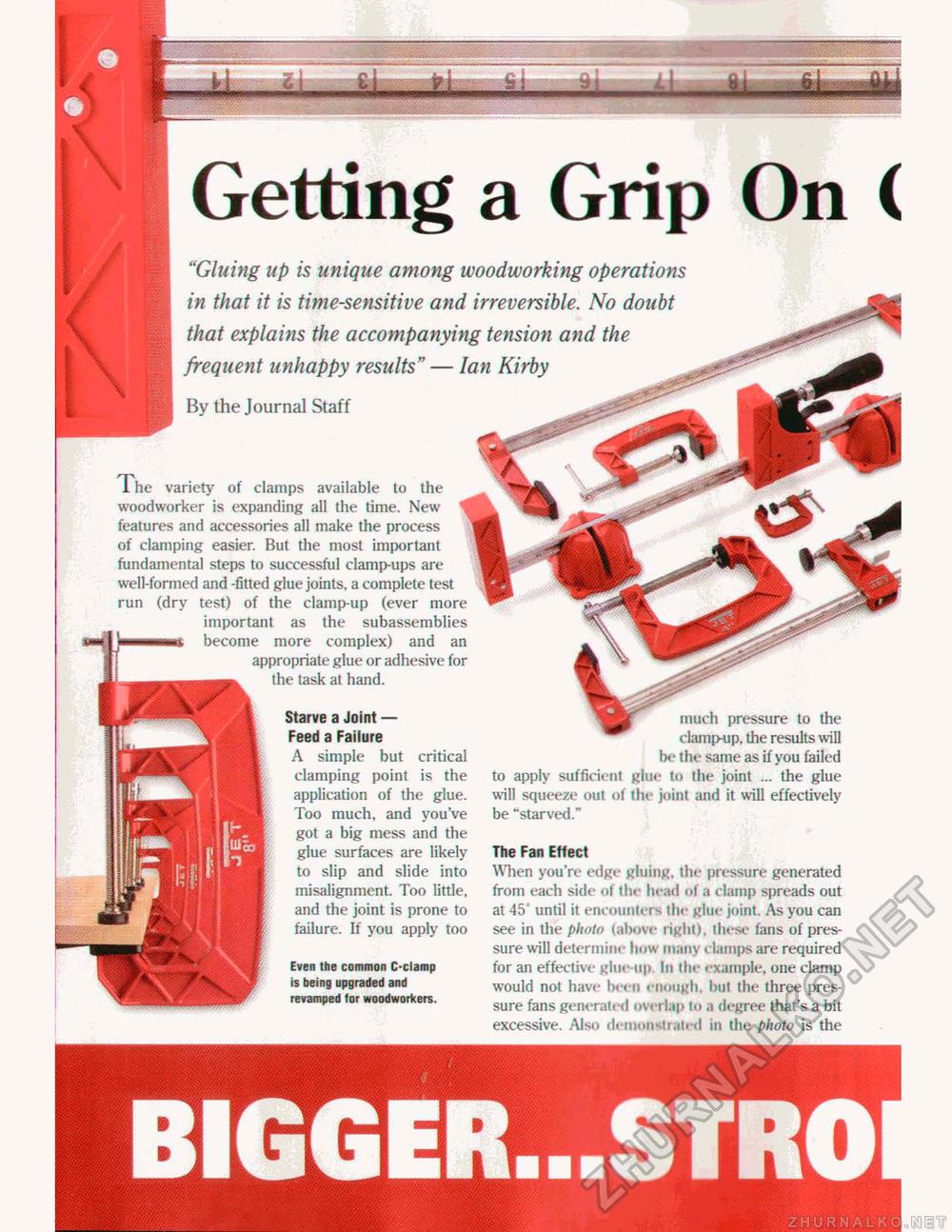

Getting a Grip On ( "Gluing up is unique among woodworking operations in that it is time-sensitive and irreversible. No doubt that explains the accompanying tension and the frequent unhappy results' — Ian Kirby By the Journal Staff 1 he variety of clamps available to the woodworker is expanding all the time. New features and accessories all make the process of clamping easier. But the most important fundamental steps to successful clamp-ups are well-formed and -fitted glue joints, a complete test run (dry test) of the clamp-up (ever more important as the subassemblies become more complex) and an appropriate glue or adhesive for the task at hand. Starve a Joint — Feed a Failure A simple but critical clamping point is the application of the glue. Too much, and you've got a big mess and the glue surfaces are likely to slip and slide into misalignment. Too little, and the joint is prone to failure. If you apply too Even the common C*clamp is being upgraded and revamped for woodworkers. much pressure to the clamp-up. the results will bo the same as if you failed to apply sufficient glut- to the joint ... the glue will squeeze out of the joint and it will effectively be "starved." The Fan Effect When you're edge gluing, tin- pressure generated from each side of the head of a clamp spreads out at 45s until it encounters tin glue joint. As you can see in the photo (above right), these fans of pressure will determine how many clamps are required for an effective glue-up In the example, oiie clamp would not have been enough, but the three pressure fans generated overlap to .1 degree that's a bit excessive. Also deinoiistr.ited in the photo is the |