Woodworker's Journal 2006-30-5, страница 7

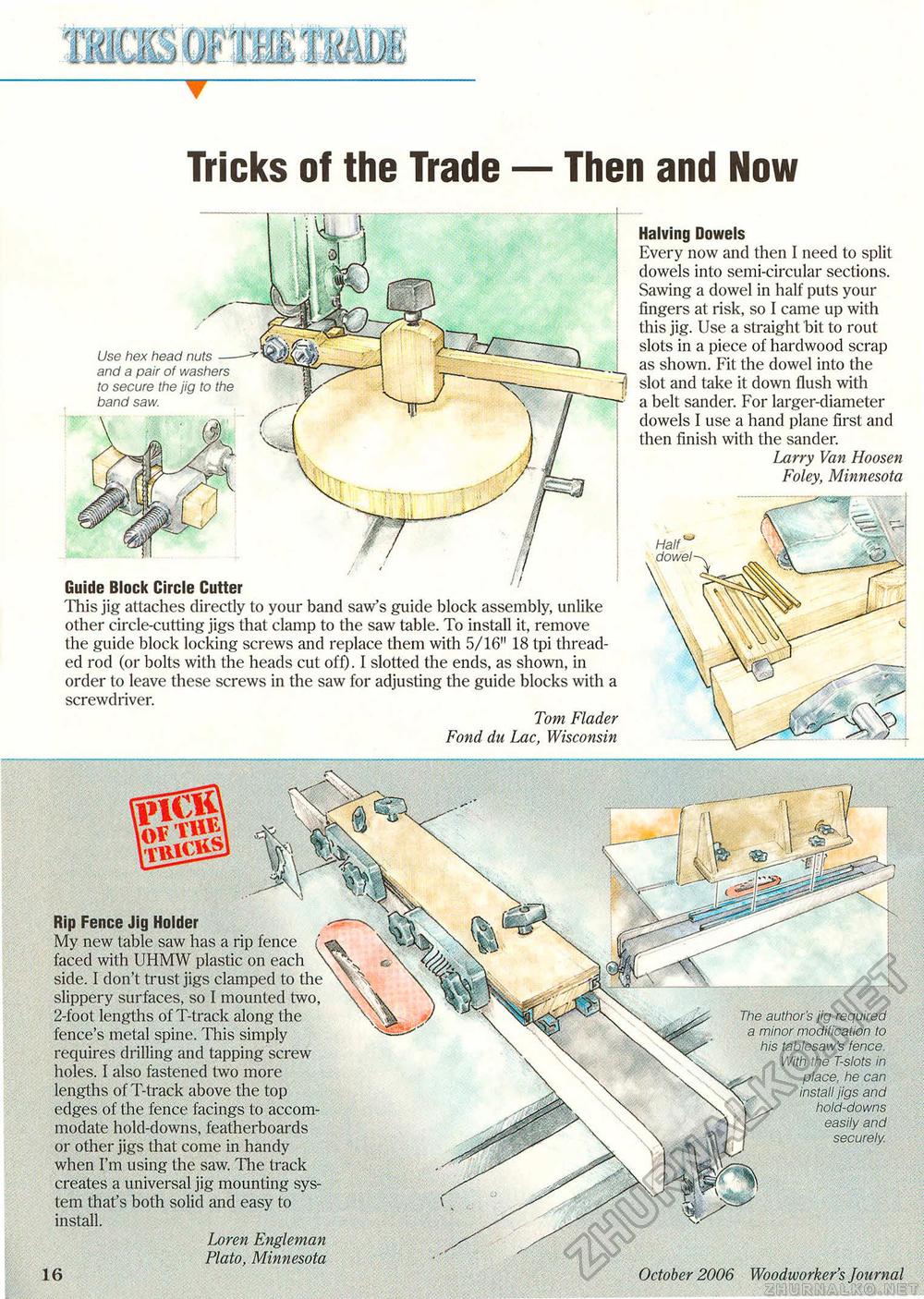

▼ Tricks of the Trade — Then and NowHalving Dowels Every now and then I need to split dowels into semi-circular sections. Sawing a dowel in half puts your fingers at risk, so I came up with this jig. Use a straight bit to rout slots in a piece of hardwood scrap as shown. Fit the dowel into the slot and take it down flush with a belt sander. For larger-diameter dowels I use a hand plane first and then finish with the sander. Larry Van Hoosen Foley, Minnesota Guide Block Circle Cutter This jig attaches directly to your band saw's guide block assembly, unlike other circle-cutting jigs that clamp to the saw table. To install it, remove the guide block locking screws and replace them with 5/16" 18 tpi threaded rod (or bolts with the heads cut off). I slotted the ends, as shown, in order to leave these screws in the saw for adjusting the guide blocks with a screwdriver. Tom Flader Fond du Lac, Wisconsin Use hex head nuts and a pair of washers to secure the jig to the band saw. Half dowel- ' < , Still v' October 2006 Woodworker's Journal Rip Fence Jig Holder My new table saw has a rip fence faced with UHMW plastic on each side. I don't trust jigs clamped to the slippery surfaces, so I mounted two, 2-foot lengths of T-track along the fence's metal spine. This simply requires drilling and tapping screw holes. I also fastened lengths of T-track a edges of the fence modate hold-downs, or other jigs that come when I'm using the saw. The creates a universal jig mounting system that's both solid and easy to install. Ujren Engleman Plato, Minnesota 16 The author's jig required a minor modification to his tablesaw's fence. With the T-slots in place, he can install jigs and hold-downs easily and securely. |