Woodworker's Journal 2008-32-2, страница 76

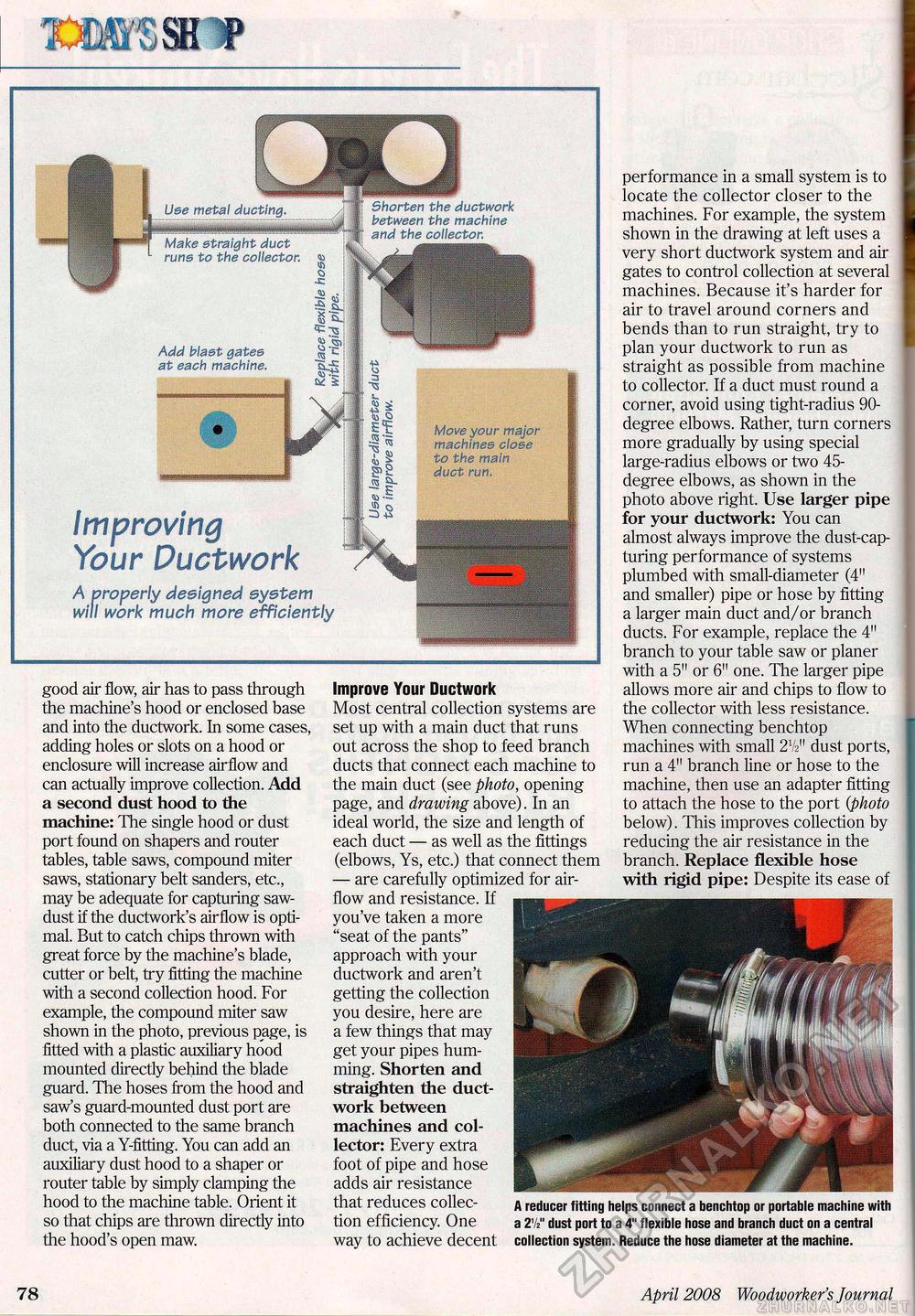

rmm p Shorten the ductwork between the machine and the collector. Add blast gates at each machine. Improving Your Ductwork A properly designed system will work much more efficiently good air flow, air has to pass through the machine's hood or enclosed base and into the ductwork. In some cases, adding holes or slots on a hood or enclosure will increase airflow and can actually improve collection. Add a second dust hood to the machine: The single hood or dust port found on shapers and router tables, table saws, compound miter saws, stationary belt sanders, etc., may be adequate for capturing sawdust if the ductwork's airflow is optimal. But to catch chips thrown with great force by the machine's blade, cutter or belt, try fitting the machine with a second collection hood. For example, the compound miter saw shown in the photo, previous page, is fitted with a plastic auxiliary hood mounted directly behind the blade guard. The hoses from the hood and saw's guard-mounted dust port are both connected to the same branch duct, via a Y-fitting. You can add an auxiliary dust hood to a shaper or router table by simply clamping the hood to the machine table. Orient it so that chips are thrown directly into the hood's open maw. Improve Your Ductwork Most central collection systems are set up with a main duct that runs out across the shop to feed branch ducts that connect each machine to the main duct (see photo, opening page, and drawing above). In an ideal world, the size and length of each duct — as well as the fittings (elbows, Ys, etc.) that connect them — are carefully optimized for airflow and resistance. If you've taken a more "seat of the pants" approach with your ductwork and aren't getting the collection you desire, here are a few things that may get your pipes humming. Shorten and straighten the ductwork between machines and collector: Every extra foot of pipe and hose adds air resistance that reduces collection efficiency. One way to achieve decent performance in a small system is to locate the collector closer to the machines. For example, the system shown in the drawing at left uses a very short ductwork system and air gates to control collection at several machines. Because it's harder for air to travel around corners and bends than to run straight, try to plan your ductwork to run as straight as possible from machine to collector. If a duct must round a corner, avoid using tight-radius 90-degree elbows. Rather, turn corners more gradually by using special large-radius elbows or two 45-degree elbows, as shown in the photo above right. Use larger pipe for your ductwork: You can almost always improve the dust-capturing performance of systems plumbed with small-diameter (4" and smaller) pipe or hose by fitting a larger main duct and/or branch ducts. For example, replace the 4" branch to your table saw or planer with a 5" or 6" one. The larger pipe allows more air and chips to flow to the collector with less resistance. When connecting benchtop machines with small 2!4" dust ports, run a 4" branch line or hose to the machine, then use an adapter fitting to attach the hose to the port (photo below). This improves collection by reducing the air resistance in the branch. Replace flexible hose with rigid pipe: Despite its ease of A reducer fitting helps connect a benchtop or portable machine with a 2Yz" dust port to a 4" flexible hose and branch duct on a central collection system. Reduce the hose diameter at the machine. 78 April 2008 Woodworker's Journal |