Woodworker's Journal 2008-32-3, страница 66

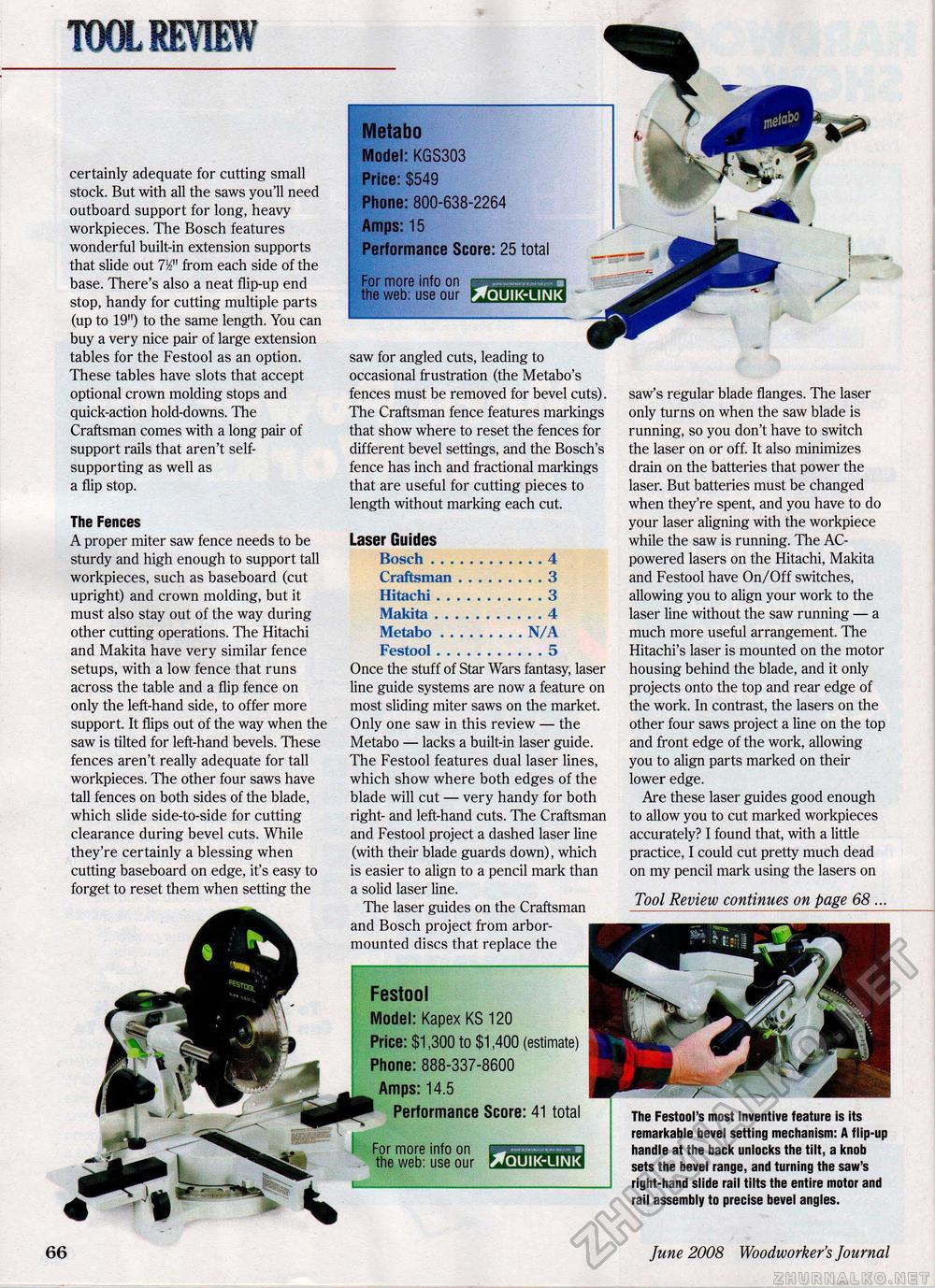

more info on web: use our PjJ'l'JIKHma TOOL REVIEW certainly adequate for cutting small stock. But with all the saws you'll need outboard support for long, heavy workpieces. The Bosch features wonderful built-in extension supports that slide out 7M" from each side of the base. There's also a neat flip-up end stop, handy for cutting multiple parts (up to 19") to the same length. You can buy a very nice pair of large extension tables for the Festool as an option. These tables have slots that accept optional crown molding stops and quick-action hold-downs. The Craftsman comes with a long pair of support rails that aren't self-supporting as well as a flip stop. The Fences A proper miter saw fence needs to be sturdy and high enough to support tall workpieces, such as baseboard (cut upright) and crown molding, but it must also stay out of the way during other cutting operations. The Hitachi and Makita have very similar fence setups, with a low fence that runs across the table and a flip fence on only the left-hand side, to offer more support. It flips out of the way when the saw is tilted for left-hand bevels. These fences aren't really adequate for tall workpieces. The other four saws have tall fences on both sides of the blade, which slide side-to-side for cutting clearance during bevel cuts. While they're certainly a blessing when cutting baseboard on edge, it's easy to forget to reset them when setting the The Festool's most inventive feature is its remarkable bevel setting mechanism: A flip-up handle at the back unlocks the tilt, a knob sets the bevel range, and turning the saw's right-hand slide rail tilts the entire motor and rail assembly to precise bevel angles. Festool Model: Kapex KS120 Price: $1,300 to $1,400 (estimate) Phone: 888-337-8600 Amps: 14.5 Performance Score: 41 total saw's regular blade flanges. The laser only turns on when the saw blade is running, so you don't have to switch the laser on or off. It also minimizes drain on the batteries that power the laser. But batteries must be changed when they're spent, and you have to do your laser aligning with the workpiece while the saw is running. The AC-powered lasers on the Hitachi, Makita and Festool have On/Off switches, allowing you to align your work to the laser line without the saw running — a much more useful arrangement. The Hitachi's laser is mounted on the motor housing behind the blade, and it only projects onto the top and rear edge of the work. In contrast, the lasers on the other four saws project a line on the top and front edge of the work, allowing you to align parts marked on their lower edge. Are these laser guides good enough to allow you to cut marked workpieces accurately? I found that, with a little practice, I could cut pretty much dead on my pencil mark using the lasers on Tool Review continues on page 68 ... Metabo Model: KGS303 Price: $549 Phone: 800-638-2264 Amps: 15 Performance Score: 25 total For more info on the web: use our saw for angled cuts, leading to occasional frustration (the Metabo's fences must be removed for bevel cuts). The Craftsman fence features markings that show where to reset the fences for different bevel settings, and the Bosch's fence has inch and fractional markings that are useful for cutting pieces to length without marking each cut. Laser Guides Bosch............4 Craftsman.........3 Hitachi...........3 Makita...........4 Metabo.........N/A Festool...........5 Once the stuff of Star Wars fantasy, laser line guide systems are now a feature on most sliding miter saws on the market. Only one saw in this review — the Metabo — lacks a built-in laser guide. The Festool features dual laser lines, which show where both edges of the blade will cut — very handy for both right- and left-hand cuts. The Craftsman and Festool project a dashed laser line (with their blade guards down), which is easier to align to a pencil mark than a solid laser line. The laser guides on the Craftsman and Bosch project from arbor-mounted discs that replace the 66 June 2008 Woodworker's Journal |