Woodworker's Journal 2008-32-5, страница 75

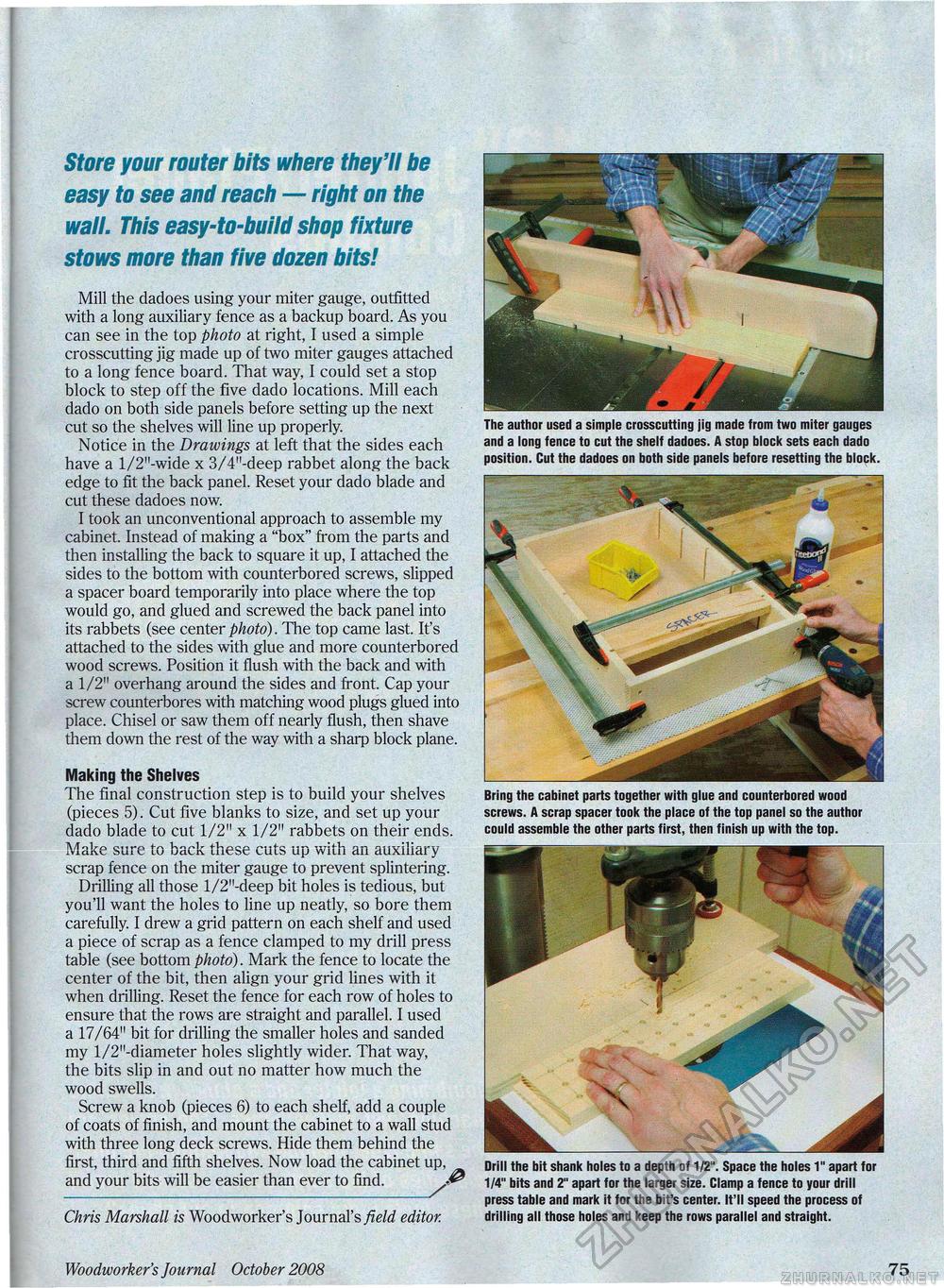

Store your router bits where they'll be easy to see and reach — right on the wall. This easy-to-build shop fixture stows more than five dozen bits! Mill the dadoes using your miter gauge, outfitted with a long auxiliary fence as a backup board. As you can see in the top photo at right, I used a simple crosscutting jig made up of two miter gauges attached to a long fence board. That way, I could set a stop block to step off the five dado locations. Mill each dado on both side panels before setting up the next cut so the shelves will line up properly. Notice in the Drawings at left that the sides each have a l/2"-wide x 3/4"-deep rabbet along the back edge to fit the back panel. Reset your dado blade and cut these dadoes now. I took an unconventional approach to assemble my cabinet. Instead of making a "box" from the parts and then installing the back to square it up, I attached the sides to the bottom with counterbored screws, slipped a spacer board temporarily into place where the top would go, and glued and screwed the back panel into its rabbets (see center photo). The top came last. It's attached to the sides with glue and more counterbored wood screws. Position it flush with the back and with a 1/2" overhang around the sides and front. Cap your screw counterbores with matching wood plugs glued into place. Chisel or saw them off nearly flush, then shave them down the rest of the way with a sharp block plane. The author used a simple crosscutting jig made from two miter gauges and a long fence to cut the shelf dadoes. A stop block sets each dado position. Cut the dadoes on both side panels before resetting the block, Bring the cabinet parts together with glue and counterbored wood screws. A scrap spacer took the place of the top panel so the author could assemble the other parts first, then finish up with the top. Drill the bit shank holes to a depth of 1/2". Space the holes 1" apart for 1/4" bits and 2" apart for the larger size. Clamp a fence to your drill press table and mark it for the bit's center. It'll speed the process of drilling all those holes and keep the rows parallel and straight. Making the Shelves The final construction step is to build your shelves (pieces 5). Cut five blanks to size, and set up your dado blade to cut 1/2" x 1/2" rabbets on their ends. Make sure to back these cuts up with an auxiliary scrap fence on the miter gauge to prevent splintering. Drilling all those l/2"-deep bit holes is tedious, but you'll want the holes to line up neatly, so bore them carefully. I drew a grid pattern on each shelf and used a piece of scrap as a fence clamped to my drill press table (see bottom photo). Mark the fence to locate the center of the bit, then align your grid lines with it when drilling. Reset the fence for each row of holes to ensure that the rows are straight and parallel. I used a 17/64" bit for drilling the smaller holes and sanded my l/2"-diameter holes slightly wider. That way, the bits slip in and out no matter how much the wood swells. Screw a knob (pieces 6) to each shelf, add a couple of coats of finish, and mount the cabinet to a wall stud with three long deck screws. Hide them behind the first, third and fifth shelves. Now load the cabinet up, and your bits will be easier than ever to find. Chris Marshall is Woodworker's Journal's field editor. Woodworker's Journal October 2008 75 |