Woodworker's Journal 2008-32-6, страница 35

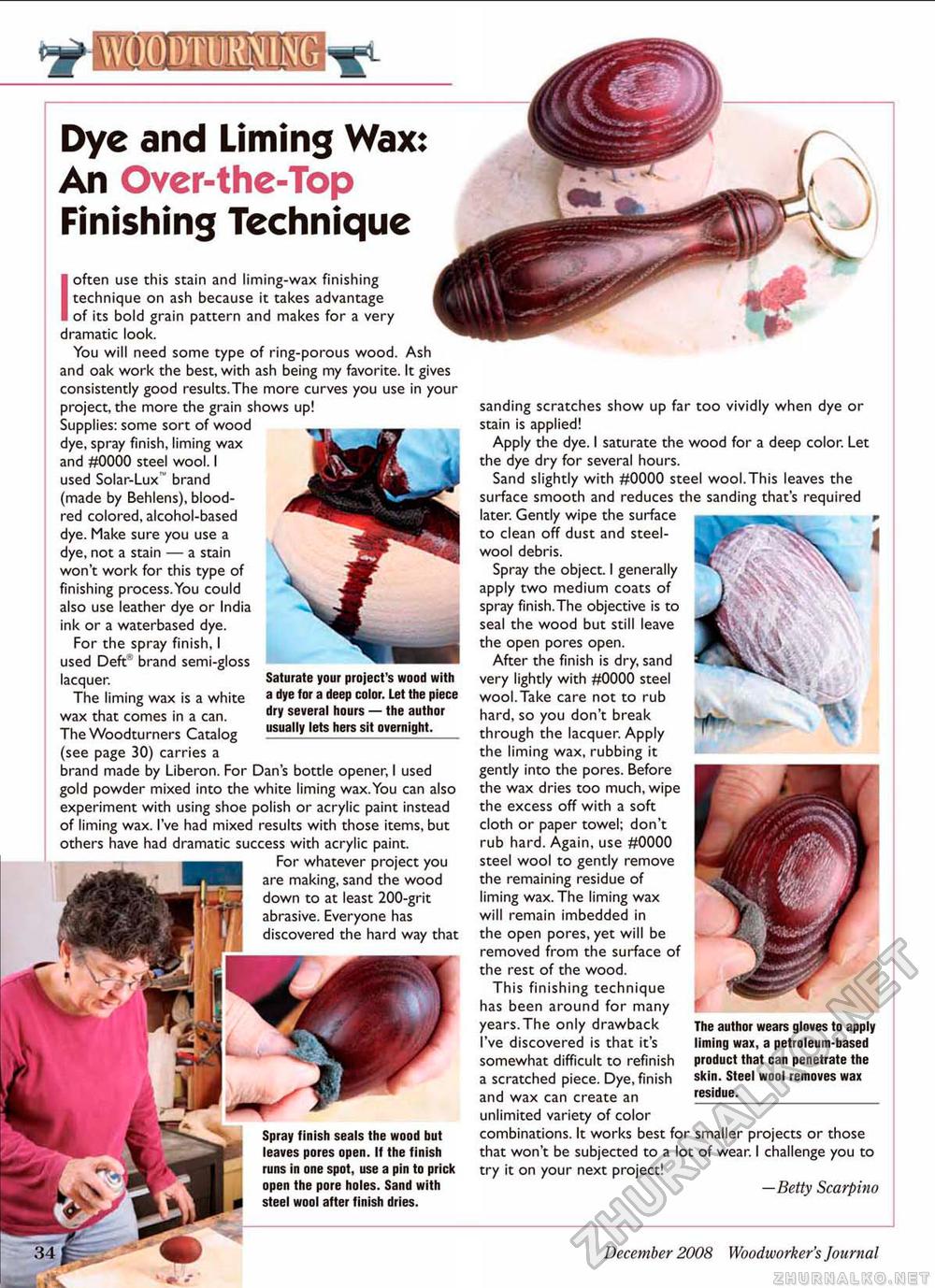

sanding scratches show up far too vividly when dye or stain is applied! Apply the dye. I saturate the wood for a deep color. Let the dye dry for several hours. Sand slightly with #0000 steel wool. This leaves the surface smooth and reduces the sanding that's required later. Gently wipe the surface ' to clean off dust and steel- wool debris. SK Spray the object. I generally \ \ apply two medium coats of spray finish,The objective is to A seal the wood but still leave the open pores open. After the finish is dry, sand » A \ very lightly with #0000 steel woo!. Take care not to rub hard, so you don't break >tA~ through the lacquer. Apply the liming wax, rubbing it gently into the pores. Before the wax dries too much, wipe the excess off with a soft cloth or paper towel; don't rub hard. Again, use #0000 steel wool to gently remove the remaining residue of liming wax. The liming wax will remain imbedded in the open pores, yet will be removed from the surface of the rest of the wood. This finishing technique has been around for many years. The only drawback I've discovered ts that it's somewhat difficult to refinish a scratched piece. Dye, finish and wax can create an unlimited variety of color combinations. It works best for smaller projects or those that won't be subjected to a lot of wear I challenge you to try it on your next project! —Betty Scarpino The author wears gloves to apply liming wax, a petroleum-based product that can penetrate the skin. Steel wool removes wax residue. 35 December 2008 Woodworker's Journal Dye and Liming Wax: An Over-thc-Top Finishing Technique I often use this stain and iiming-wax finishing technique on ash because it takes advantage of its bold grain pattern and makes for a very dramatic look. You will need some type of ring-porous wood. Ash and oak work the best, with ash being my favorite. It gives Consistently good results.The more curves you use in your project, the more the grain shows up! Supplies: some sort of wood dye, spray finish, liming wax and #0000 steel wool. I used Solar-Lux brand (made by Behlens), blood-red colored, alcohol-based dye. Make sure you use a dye, not a stain — a stain won't work for this type of finishing process. You could also use leather dye or India ink or a waterbased dye. For the spray finish, I used Deft' brand semi-gloss lacquer. The liming wax is a white wax that comes in a can. The Woodturners Catalog (see page 30) carries a brand made by Liberon. For Dan's bottle opener, I used gold powder mixed into the white liming wax.You can also experiment with using shoe polish or acrylic paint instead of liming wax. I've had mixed results with those items, but others have had dramatic success with acrylic paint. For whatever project you are making, sand the wood down to at least 200-grit abrasive. Everyone has discovered the hard way that Saturate your project's wood with a dye for a deep color. Let the piece dry several hours — the author usually lets hers sit overnight. Spray finish seals the wood but leaves pores open. If the finish runs in one spot, use a pin to prick open the pore holes. Sand with steel wool after finish dries. |