Woodworker's Journal 2008-32-6, страница 39

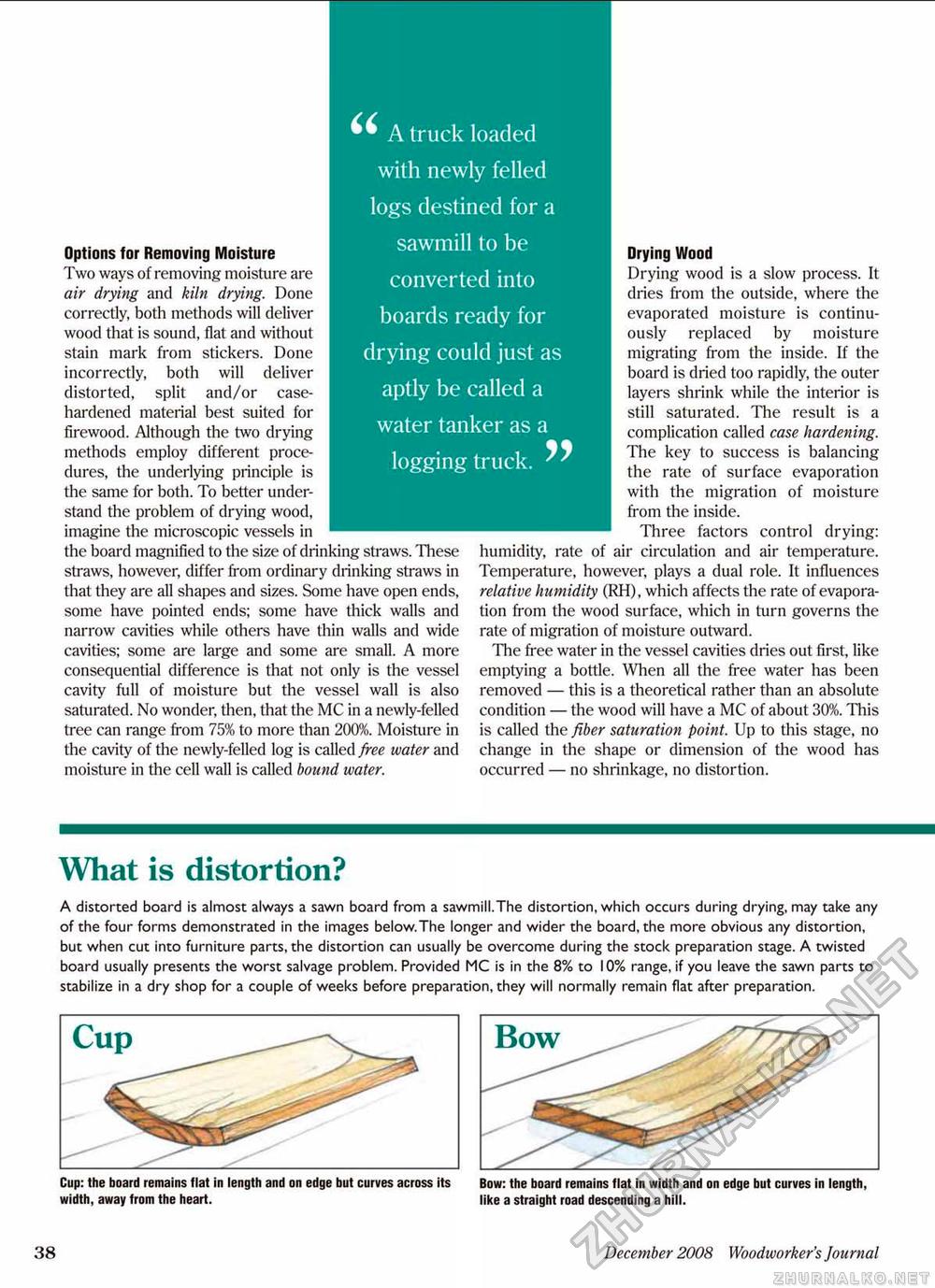

A truck loaded Options tor Removing Moisture Two ways of removing moisture are air drying and kiln drying. Done correctly, both methods will deliver wood that is sound, flat and without stain mark from stickers. Done incorrectly, both will deliver distorted, split and/or case-hardened material best suited for firewood. Although the two drying methods employ different procedures, the underlying principle is the same for both. To better understand the problem of drying wood, imagine the microscopic vessels in the board magnified to the size of drinking straws. These straws, however, differ from ordinary drinking straws in that they are all shapes and sizes. Some have open ends, some have pointed ends; some have thick walls and narrow cavities while others have thin walls and wide cavities; some are large and some are small. A more consequential difference is that not only is the vessel cavity full of moisture but the vessel wall is also saturated. No wonder, then, that the MC in a newly-felled tree can range from 75% to more than 200%. Moisture in the cavity of the newly-felled log is called free water and moisture in the cell wall is called bound water. with newly felled logs destined for a sawmill to be converted into boards ready for drying could just as aptly be called a water tanker as a logging truck. Drying Wood Drying wood is a slow process. It dries from the outside, where the evaporated moisture is continuously replaced by moisture migrating from the inside. If the board is dried too rapidly, the outer layers shrink while the interior is still saturated. The result is a complication called case hardening. The key to success is balancing the rate of surface evaporation with the migration of moisture from the inside. Three factors control drying: humidity, rate of air circulation and air temperature. Temperature, however, plays a dual role. It influences relative humidity (RH), which affects the rate of evaporation from the wood surface, which in turn governs the rate of migration of moisture outward. The free water in the vessel cavities dries out first, like emptying a bottle. When all the free water has been removed — this is a theoretical rather than an absolute condition — the wood will have a MC of about 30%. This is called the fiber saturation point. Up to this stage, no change in the shape or dimension of the wood has occurred — no shrinkage, no distortion. What is distortion? A distorted board is almost always a sawn board from a sawmill.The distortion, which occurs during drying, may take any of the four forms demonstrated in the images below.The longer and wider the board, the more obvious any distortion, but when cut into furniture parts, the distortion can usually be overcome during the stock preparation stage. A twisted board usually presents the worst salvage problem. Provided MC is in the 8% to 10% range, if you leave the sawn parts to stabilize in a dry shop for a couple of weeks before preparation, they will normally remain flat after preparation. Cup: the board remains flat in length and on edge but curves across its width, away from the heart. Bow: the board remains flat in width and on edge but curves in length, like a straight road descending a hill. Bow 38 December 2008 Woodworker's Journal |