Woodworker's Journal 2009-33-2, страница 25

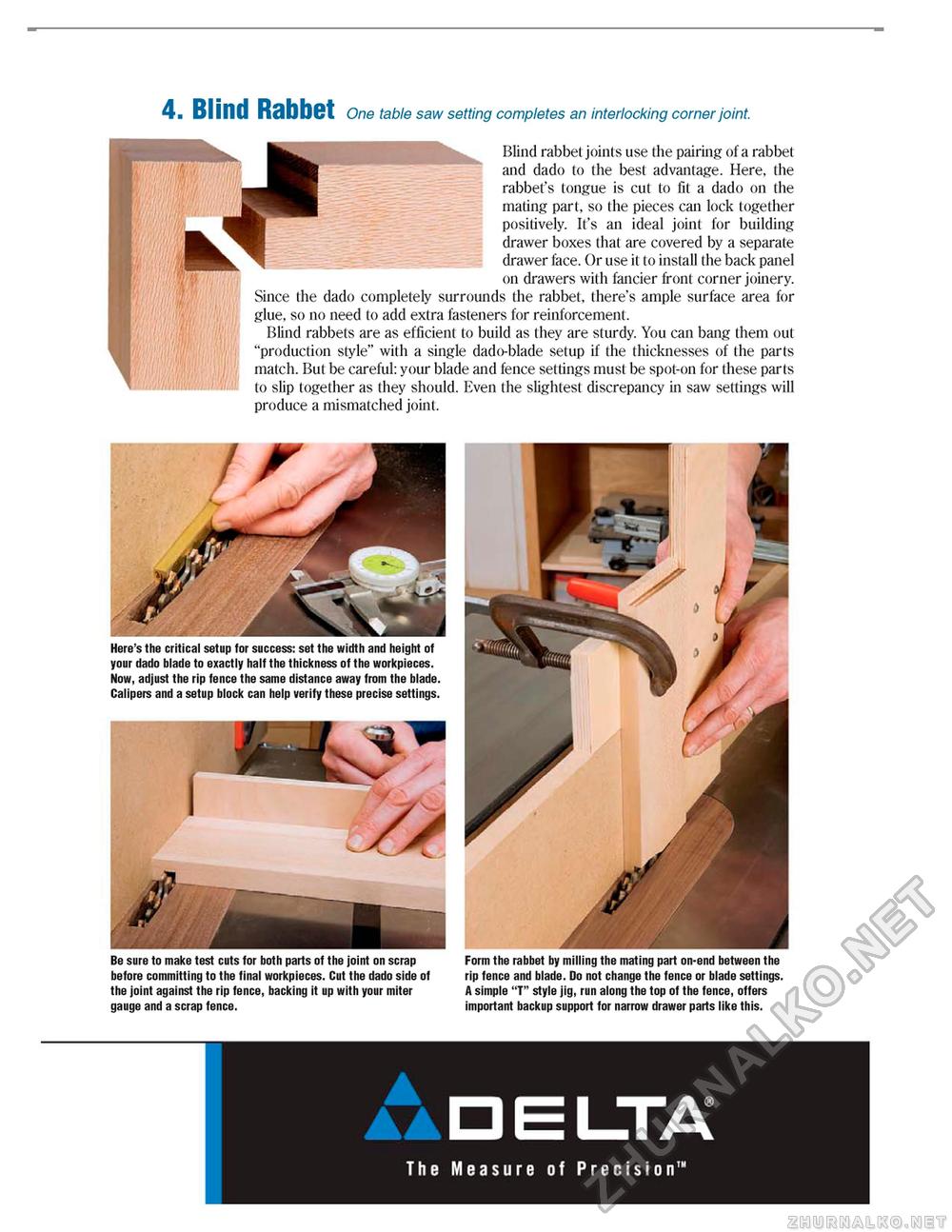

4. Blind Rabbet One table saw setting completes an interlocking corner joint. Blind rabbet joints use the pairing of a rabbet and dado to the best advantage. Here, the rabbet's tongue is cut to fit a dado on the mating part, so the pieces can lock together positively. It's an ideal joint for building drawer boxes that are covered by a separate drawer face. Or use it to install the back panel on drawers with fancier front corner joinery. Since the dado completely surrounds the rabbet, there's ample surface area for glue, so no need to add extra fasteners for reinforcement. Blind rabbets are as efficient to build as they are sturdy. You can bang them out "production style" with a single dado-blade setup if the thicknesses of the parts match. But be careful: your blade and fence settings must be spot-on for these parts to slip together as they should. Even the slightest discrepancy in saw settings will produce a mismatched joint. Here's the critical setup for success: set the width and height of your dado blade to exactly half the thickness of the workpieces. Now, adjust the rip fence the same distance away from the blade. Calipers and a setup block can help verify these precise settings. Be sure to make test cuts for both parts of the joint on scrap before committing to the final workpieces. Cut the dado side of the joint against the rip fence, backing it up with your miter gauge and a scrap fence. Form the rabbet by milling the mating part on-end between the rip fence and blade. Do not change the fence or blade settings. A simple "T" style jig, run along the top of the fence, offers important backup support for narrow drawer parts like this. AdeltaThe Measure of Precision'" |