Woodworker's Journal 2009-33-2, страница 30

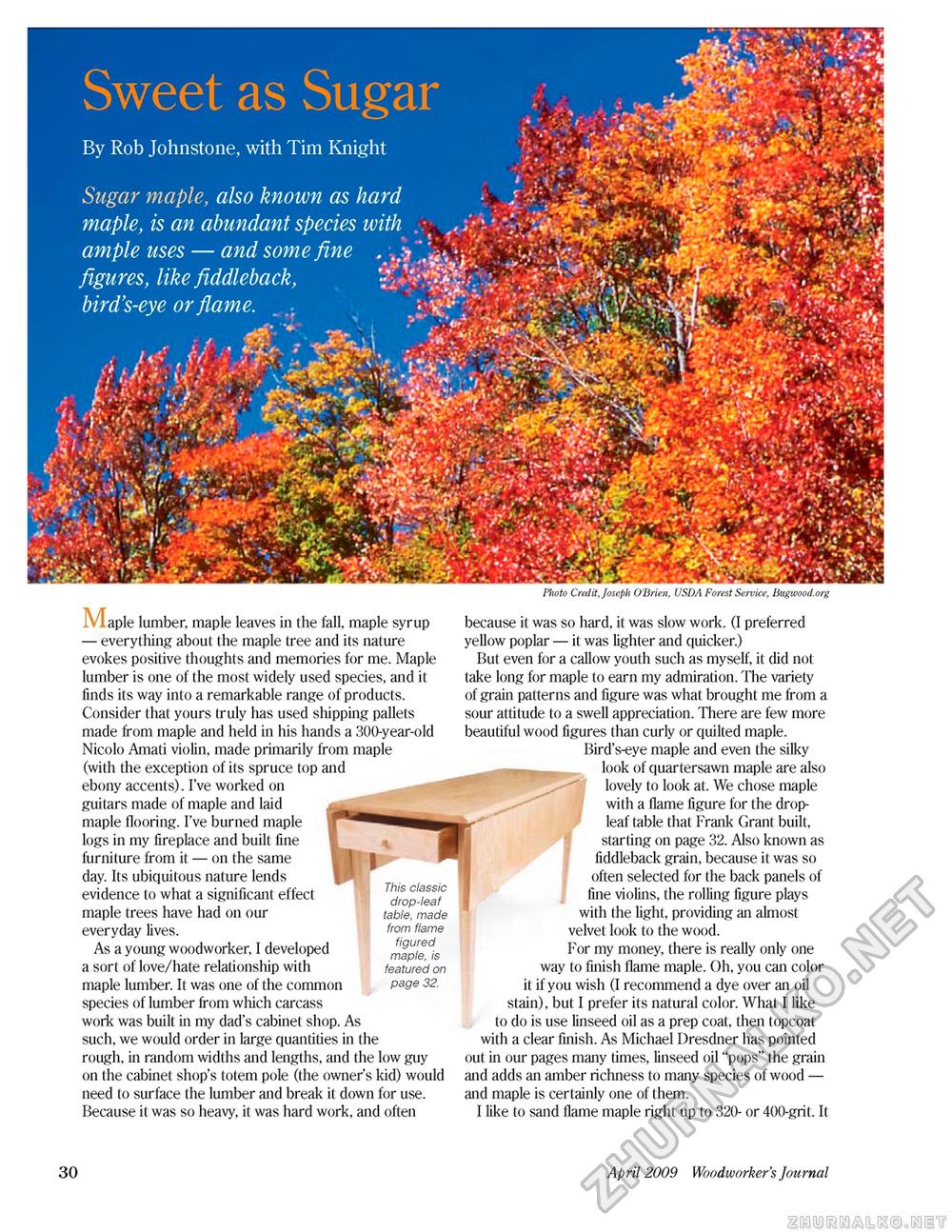

aple lumber, maple leaves in the fall, maple syrup — everything about the maple tree and its nature evokes positive thoughts and memories for me. Maple lumber is one of the most widely used species, and it finds its way into a remarkable range of products. Consider that yours truly has used shipping pallets made from maple and held in his hands a 300-year-old Nicolo Amati violin, made primarily from maple (with the exception of its spruce top and ebony accents). I've worked on guitars made of maple and laid maple flooring. I've burned maple logs in my fireplace and built fine furniture from it — on the same day. Its ubiquitous nature lends evidence to what a significant effect maple trees have had on our everyday lives. As a young woodworker, I developed a sort of love/hate relationship with maple lumber. It was one of the common species of lumber from which carcass work was built in my dad's cabinet shop. As such, we would order in large quantities in the rough, in random widths and lengths, and the low guy on the cabinet shop's totem pole (the owner's kid) would need to surface the lumber and break it down for use. Because it was so heavy, it was hard work, and often This classic drop-leaf table, made from flame figured maple, is featured on page 32. Photo Credit, Joseph O'Brien, USDA Forest Service, Bugwood.org because it was so hard, it was slow work. (I preferred yellow poplar — il was lighter and quicker.) But even for a callow youth such as myself, it did not take long for maple to earn my admiration. The variety of grain patterns and figure was what brought me from a sour attitude to a swell appreciation. There are few more beautiful wood figures than curly or quilted maple. Bird's-eye maple and even the silky look of quartersawn maple are also lovely to look at. We chose maple with a flame figure for the drop-leaf table that Frank Grant built, starting on page 32. Also known as fiddleback grain, because it was so often selected for the back panels of fine violins, the rolling figure plays with the light, providing an almost velvet look to the wood. For my money, there is really only one way to finish flame maple. Oh, you can color il if you wish (I recommend a dye over an oil stain), bul I prefer its natural color. Whal I like to do is use linseed oil as a prep coat, then topcoat with a clear finish. As Michael Dresdner has pointed out in our pages many times, linseed oil "pops" the grain aid adds an amber richness to many species of wood — and maple is certainly one of them. I like to sand flame maple right up to 320- or 400-grit. Il 30 April 2009 Woodworker's Journal |