Woodworker's Journal 2009-33-2, страница 36

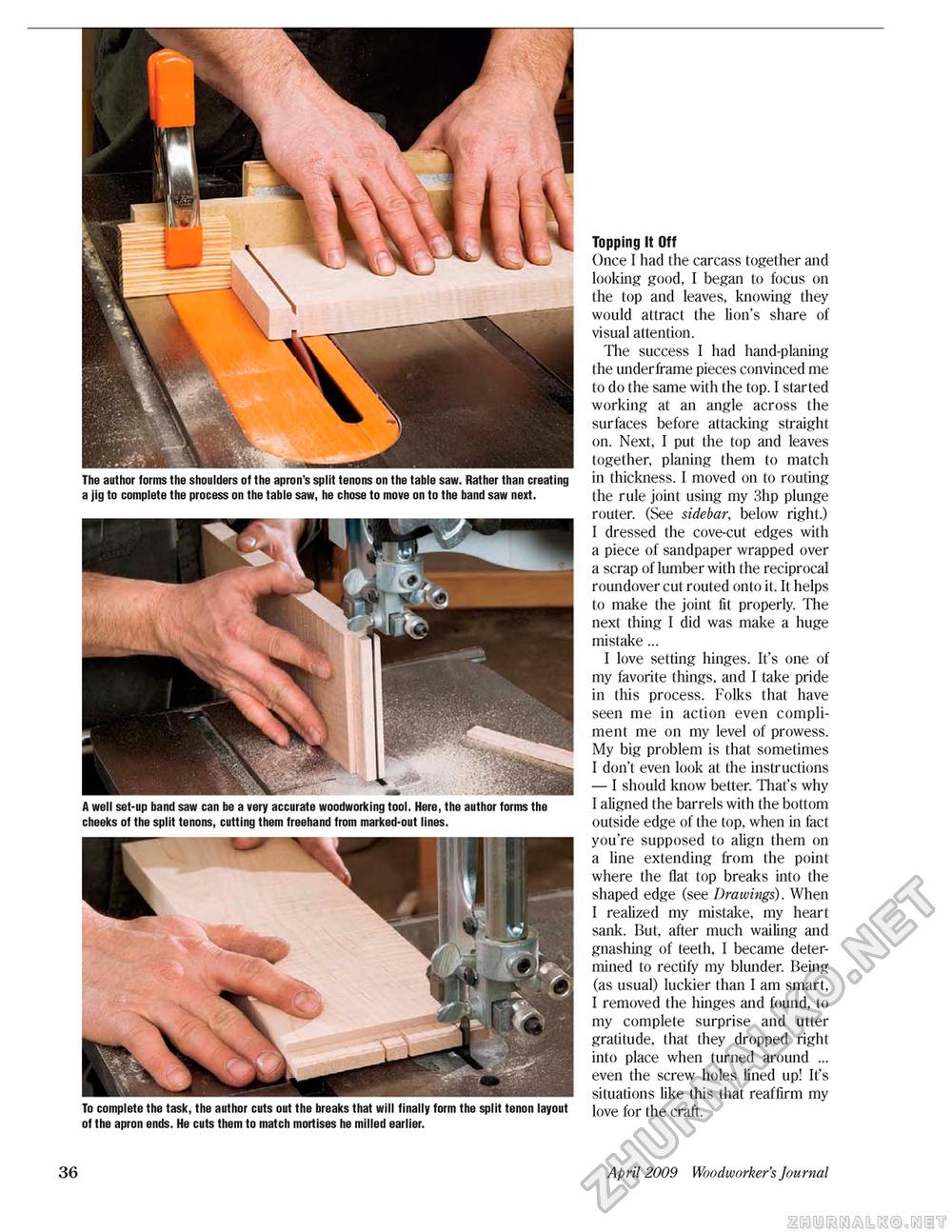

The author forms the shoulders of the apron's split tenons on the table saw. Rather than creating a jig to complete the process on the table saw, he chose to move on to the band saw next. A well set-up band saw can be a very accurate woodworking tool. Here, the author forms the cheeks of the split tenons, cutting them freehand from marked-out lines. To complete the task, the author cuts out the breaks that will finally form the split tenon layout of the apron ends. He cuts them to match mortises he milled earlier. Topping It Off Once I had the carcass together and looking good, I began to focus on the top and leaves, knowing they would attract the lion's share of visual attention. The success I had hand-planing the underframe pieces convinced me to do the same with the top. I started working at an angle across the surfaces before attacking straight on. Next, I put the top and leaves together, planing them to match in thickness. I moved on to routing the rule joint using my 3hp plunge router. (See sidebar, below right.) I dressed the cove-cut edges with a piece of sandpaper wrapped over a scrap of lumber with the reciprocal roundover cut routed onto it. It helps to make the joint fit properly. The next thing I did was make a huge mistake... I love setting hinges. It's one of my favorite tilings, and I take pride in this process. Folks that have seen me in action even compliment me on my level of prowess. My big problem is that sometimes 1 don't even look at the instructions — I should know better. That's why I aligned the barrels with the bottom outside edge of the top, when in fact you're supposed to align lliem on a line extending from the point where the flat top breaks into the shaped edge (see Drawings). When I realized my mistake, my heart sank. But, after much wailing and gnashing of teeth, I became determined to rectify my blunder. Being (as usual) luckier than I am smart, I removed the hinges and found, to my complete surprise and utter gratitude, that they dropped right into place when turned around ... even the screw holes lined up! It's situations like this that reaffirm my love for the cralt. 36 April 2009 Woodworker's Journal |