Woodworker's Journal 2010-34-1, страница 58

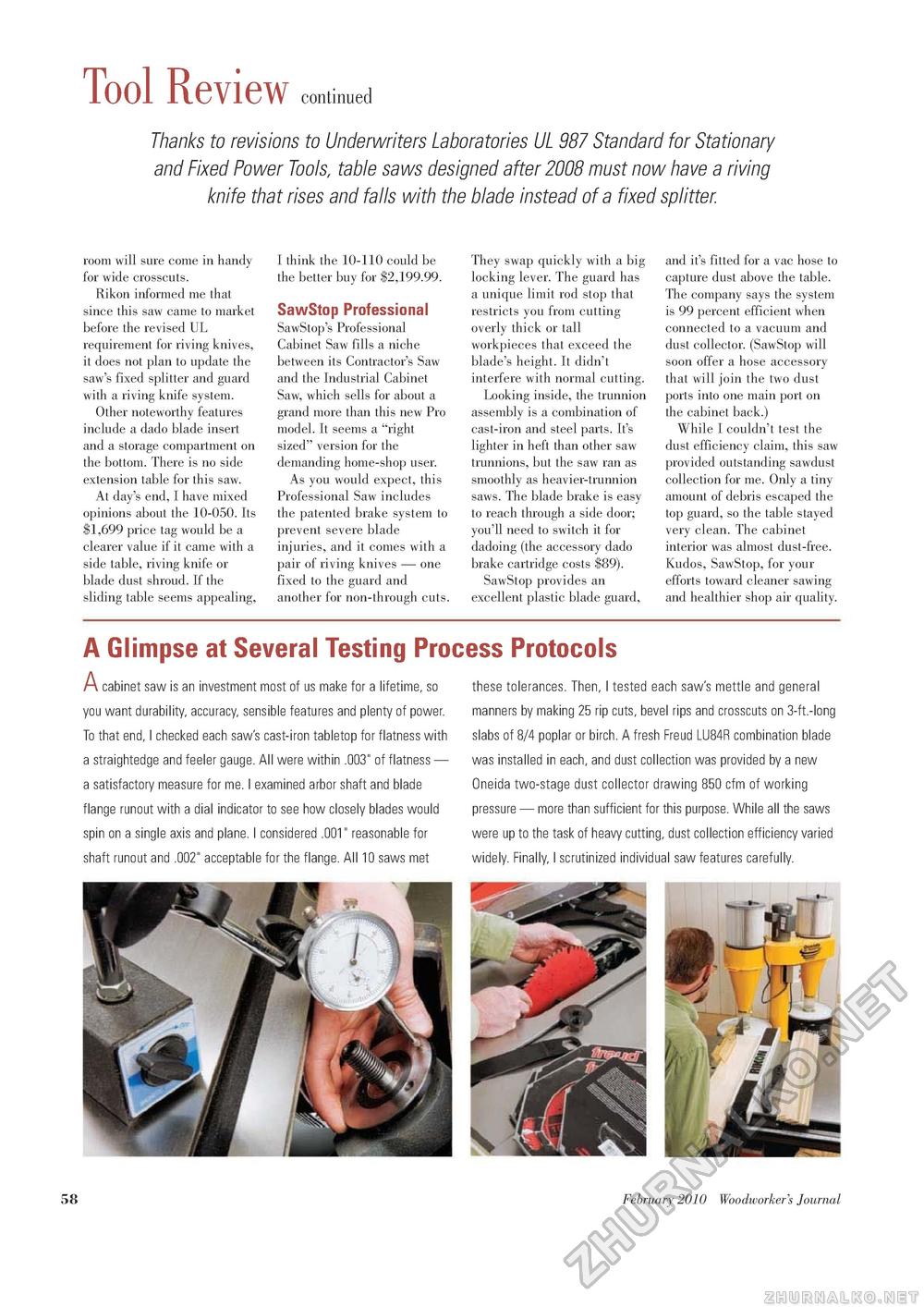

Tool Review continued Thanks to revisions to Underwriters Laboratories UL 987 Standard for Stationary and Fixed Power Tools, table saws designed after 2008 must now have a riving knife that rises and falls with the blade instead of a fixed splitter. room will sure come in handy for wide crosscuts. Rikon informed me that since this saw came to market before the revised UL requirement for riving knives, it does not plan to update the saw's fixed splitter and guard with a riving knife system. Other noteworthy features include a dado blade insert and a storage compartment on the bottom. There is no side extension table for this saw. At day's end, I have mixed opinions about the 10-050. Its $1,699 price tag would be a clearer value if it came with a side table, riving knife or blade dust shroud. If the sliding table seems appealing, I think the 10-110 could be the better buy for $2,199.99. SawStop Professional SawStop's Professional Cabinet Saw fills a niche between its Contractor's Saw and the Industrial Cabinet Saw, which sells for about a grand more than this new Pro model. It seems a "right sized" version for the demanding home-shop user. As you would expect, this Professional Saw includes the patented brake system to prevent severe blade injuries, and it comes with a pair of riving knives — one fixed to the guard and another for non-through cuts. They swap quickly with a big locking lever. The guard has a unique limit rod stop that restricts you from cutting overly thick or tall workpieces that exceed the blade's height. It didn't interfere with normal cutting. Looking inside, the trunnion assembly is a combination of cast-iron and steel parts. It's lighter in heft than other saw trunnions, but the saw ran as smoothly as heavier-trunnion saws. The blade brake is easy to reach through a side door; you'll need to switch it for dadoing (the accessory dado brake cartridge costs $89). SawStop provides an excellent plastic blade guard, and it's fitted for a vac hose to capture dust above the table. The company says the system is 99 percent efficient when connected to a vacuum and dust collector. (SawStop will soon offer a hose accessory that will join the two dust ports into one main port on the cabinet back.) While I couldn't test the dust efficiency claim, this saw provided outstanding sawdust collection for me. Only a tiny amount of debris escaped the top guard, so the table stayed very clean. The cabinet interior was almost dust-free. Kudos, SawStop, for your efforts toward cleaner sawing and healthier shop air quality. A Glimpse at Several Testing Process Protocols A cabinet saw is an investment most of us make for a lifetime, so you want durability, accuracy, sensible features and plenty of power. To that end, I checked each saw's cast-iron tabletop for flatness with a straightedge and feeler gauge. All were within .003" of flatness — a satisfactory measure for me. I examined arbor shaft and blade flange runout with a dial indicator to see how closely blades would spin on a single axis and plane. I considered .001" reasonable for shaft runout and .002" acceptable for the flange. All 10 saws met these tolerances. Then, I tested each saw's mettle and general manners by making 25 rip cuts, bevel rips and crosscuts on 3-ft.-long slabs of 8/4 poplar or birch. A fresh Freud LU84R combination blade was installed in each, and dust collection was provided by a new Oneida two-stage dust collector drawing 850 cfm of working pressure — more than sufficient for this purpose. While all the saws were up to the task of heavy cutting, dust collection efficiency varied widely. Finally, I scrutinized individual saw features carefully. 58 February 2010 Woodworker's Journal |