Woodworker's Journal 2010-34-1, страница 68

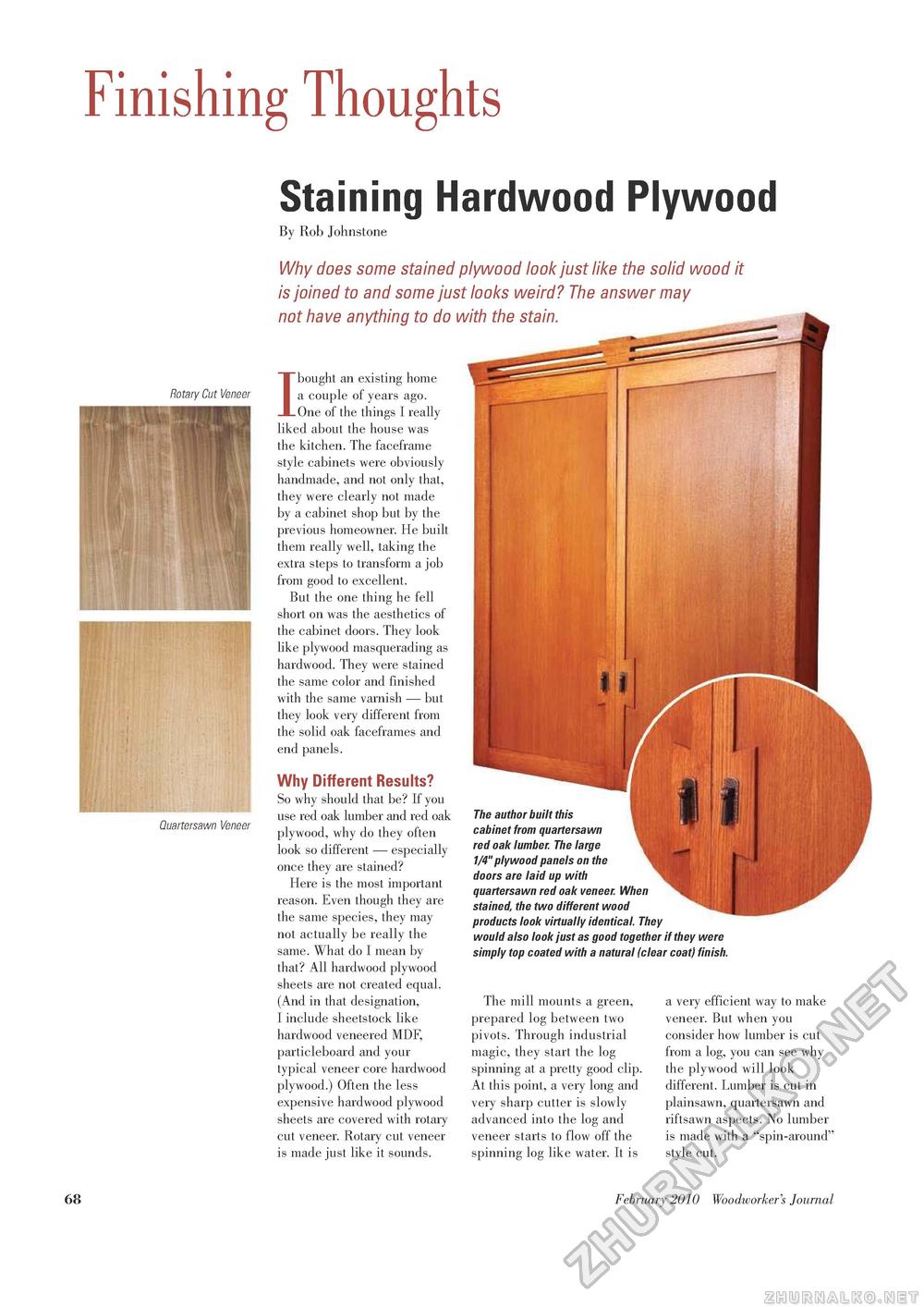

Finishing Thoughts Rotary Cut Veneer Quartersawn Veneer Staining Hardwood Plywood By Rob Johnstone Why does some stained plywood look just like the solid wood it is joined to and some just looks weird? The answer may not have anything to do with the stain. ab bought an existing home a couple of years ago. One of the things I really liked about the house was the kitchen. The faceframe style cabinets were obviously handmade, and not only that, they were clearly not made by a cabinet shop but by the previous homeowner. He built them really well, taking the extra steps to transform a job from good to excellent. But the one thing he fell short on was the aesthetics of the cabinet doors. They look like plywood masquerading as hardwood. They were stained the same color and finished with the same varnish — but they look very different from the solid oak faceframes and end panels. Why Different Results? So why should that be? If you use red oak lumber and red oak plywood, why do they often look so different — especially once they are stained? Here is the most important reason. Even though they are the same species, they may not actually be really the same. What do I mean by that? All hardwood plywood sheets are not created equal. (And in that designation, I include sheetstock like hardwood veneered MDF, particleboard and your typical veneer core hardwood plywood.) Often the less expensive hardwood plywood sheets are covered with rotary cut veneer. Rotary cut veneer is made just like it sounds. Thie author built this cabinet from quartersawn red oak lumber. The large 1/4" plywood panels on the doors are laid up with quartersawn red oak veneer. When stained, the two different wood products look virtually identical. They would also look just as good together if they were simply top coated with a natural (clear coat) finish. The mill mounts a green, prepared log between two pivots. Through industrial magic, they start the log spinning at a pretty good clip. At this point, a very long and very sharp cutter is slowly advanced into the log and veneer starts to flow off the spinning log like water. It is a very efficient way to make veneer. But when you consider how lumber is cut from a log, you can see why the plywood will look different. Lumber is cut in plainsawn, quartersawn and riftsawn aspects. No lumber is made with a "spin-around" style cut. 68 February 2010 Woodworker's Journal |