Woodworker's Journal 2010-34-2, страница 14

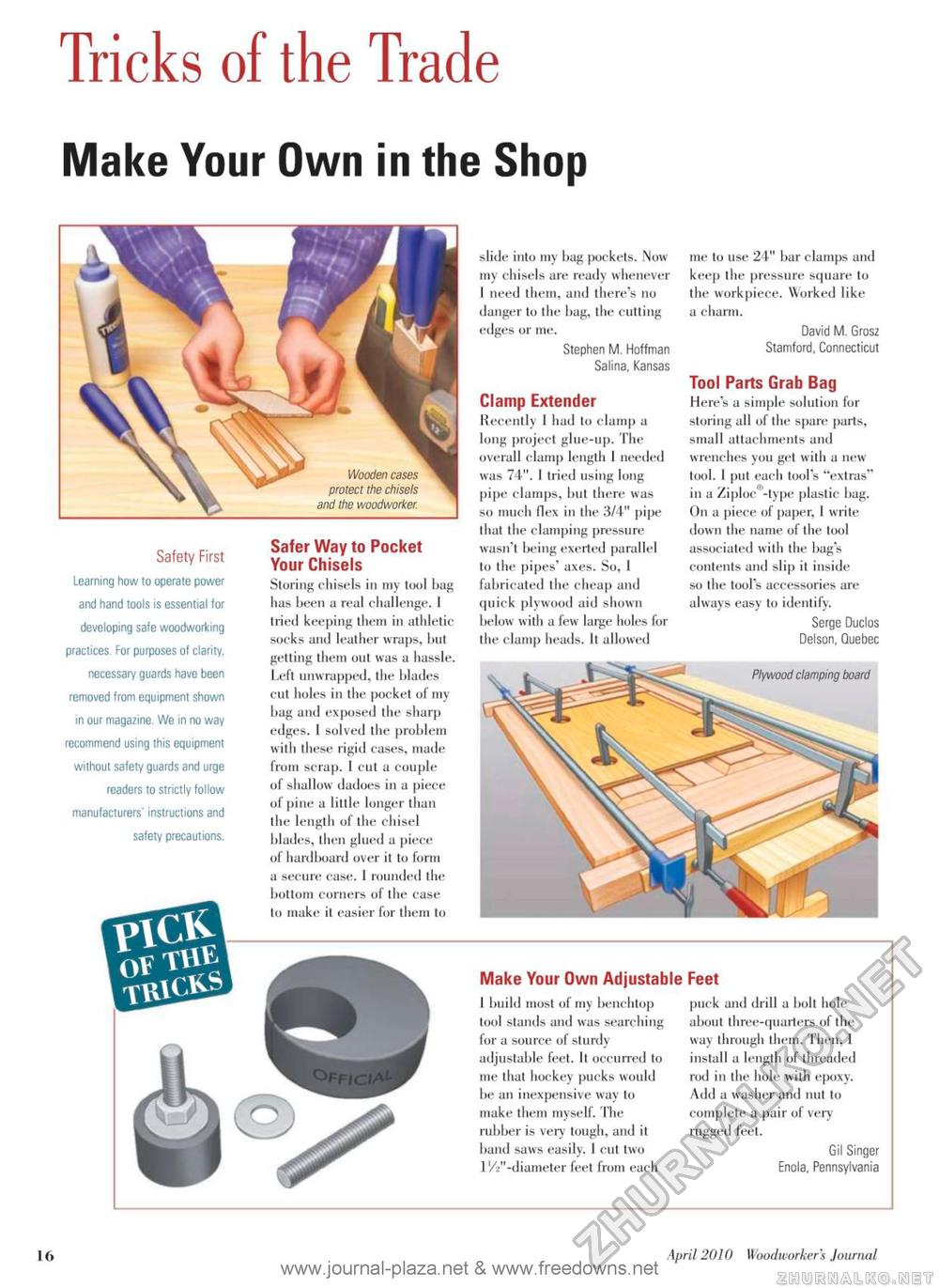

Tricks of the Trade Make Your Own in the Shop Safety First Learning how to operate power and hand tools is essential for developing safe woodworking practices. For purposes of clarity. necessary guards have been removed from equipment shown in our magazine. We in no way recommend using this equipment without safety guards and urge readers to strictly follow manufacturers' instructions and safety precautions. PICK TRICKS Safer Way to Pocket Your Chisels Storing chisels in my tool hag has been a real challenge. I tried keeping them in athletic socks and leather wraps, but getting them out was a hassle. Left unwrapped, the blades cut holes in the pocket of my hag and exposed the sharp edges. I solved the problem with these rigid cases, made from scrap. 1 cut a couple of shallow dadoes in a piece of pine a little longer than the length of the chisel blades, then glued a piece of hardboard over it to form a secure case. I rounded the bottom corners of the case to make it easier for them to slide into my bag pockets. Now my chisels are ready whenever I need them, and there's no danger to the bag, the cutting edges or me. Stephen M. Hoffman Salina, Kansas Clamp Extender Recently 1 had to clamp a long project glue-up. The overall clamp length I needed was 74". I tried using long pipe clamps, but there was so much flex in die 3/4" pipe that the clamping pressure wasn't being exerted parallel to the pipes' axes. So, 1 fabricated the cheap and quick plywood aid shown below with a fewr large holes for the clamp heads. It allowed me to use 24" bar clamps and keep the pressure square to the work piece. Worked like a charm. David M. Grosz Stamford, Connecticut Tool Parts Grab Bag Here's a simple solution for storing all of the spare parts, small attachments and wrenches you get w ith a new tool. I put each tool's "extras" in a Ziploc -type plastic bag. On a piece of paper, 1 write down the name of the tool associated with the bag's contents and slip it inside so the tool's accessories are always easy to identify. Serge Duclos Delson, Quebec Make Your Own Adjustable I build most of my benchtop tool stands and was searching for a source of sturdy adjustable feet. It occurred to me that hockey pucks would be an inexpensive way to make them myself. The rubber is very tough, and it band saws easily. I cut two 1 W-diameter feet from each Feet puck and drill a bolt hole about three-quarters of the way through them. Then, 1 install a length of threaded rod in the hole with epoxy. Add a washer and nut to complete a pair of very rugged feet. Gil Singer Enola, Pennsylvania Wooden cases protect the chisels and the woodworker. Plywood clamping board 16 April 2010 Woodworkers Jourruil |