Woodworker's Journal fall-2008, страница 14

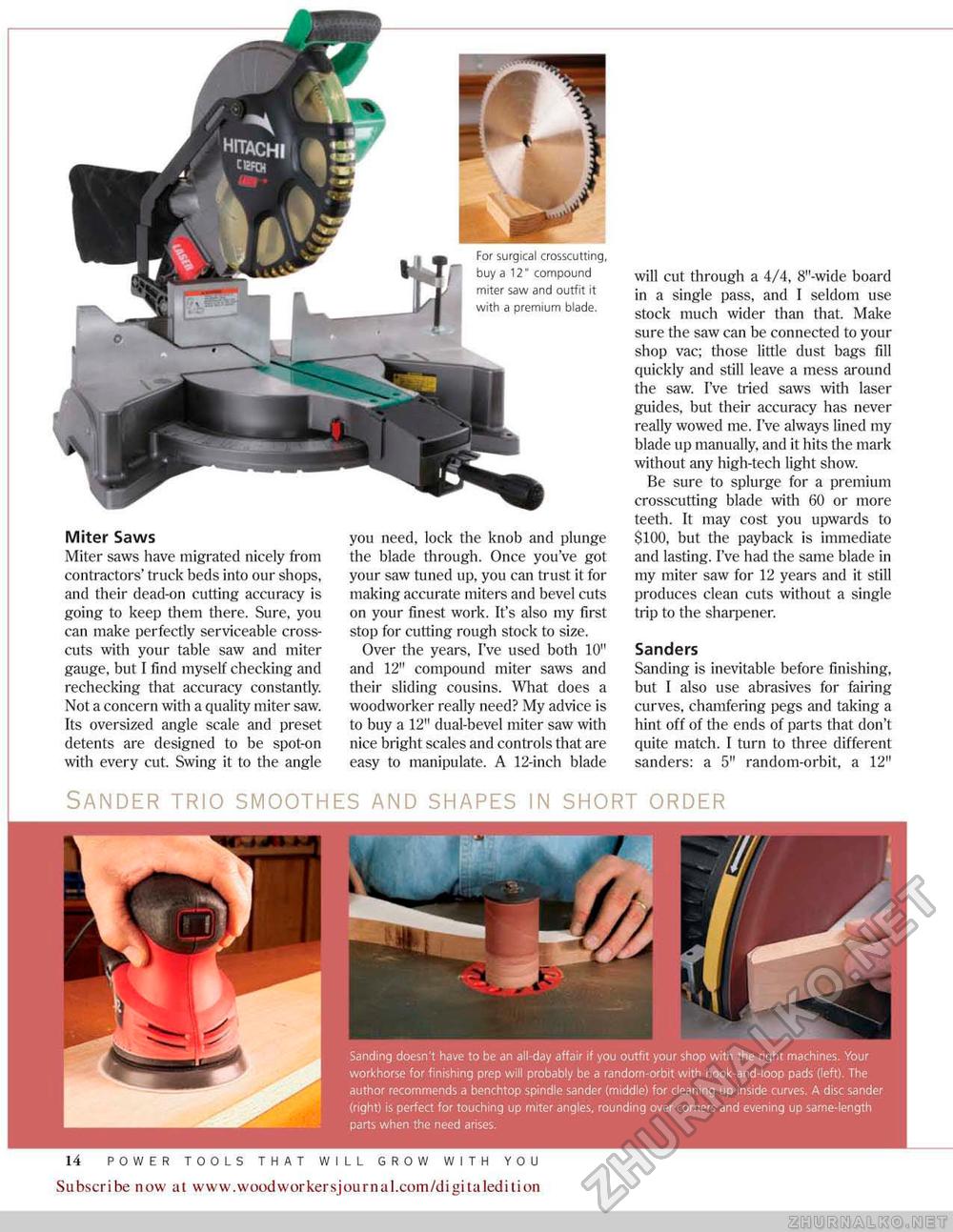

Miter Saws Miter saws have migrated nicely from contractors' truck beds into our shops, and their dead-on cutting accuracy is going to keep them there. Sure, you can make perfectly serviceable crosscuts with your table saw and miter gauge, but I find myself checking and rechecking that accuracy constantly. Not a concern with a quality miter saw. Its oversized angle scale and preset detents are designed to be spot-on with every cut Swing it to the angle you need, lock the knob and plunge the blade through. Once you've got your saw tuned up, you can trust it for making accurate miters and bevel cuts on your finest work. It's also my first stop for cutting rough stock to size. Over the years, I've used both 10" and 12" compound miter saws and their sliding cousins. What does a woodworker really need? My advice is to buy a 12" dual-bevel miter saw with nice bright scales and controls that are easy to manipulate. A 12-inch blade will cut through a 4/4, 8"-wide board in a single pass, and I seldom use stock much wider than that. Make sure the saw can be connected to your shop vac; those little dust bags fill quickly and still leave a mess around the saw. I've tried saws with laser guides, but their accuracy has never really wowed me, I've always lined my blade up manually, and it hits the mark without any high-tech light show. Be sure to splurge for a premium crosscutting blade with 60 or more teeth. It may cost you upwards to $100, but the payback is immediate and lasting. I've had the same blade in my miter saw for 12 years and it still produces clean cuts without a single trip to the sharpener. Sanders Sanding is inevitable before finishing, but I also use abrasives for fairing curves, chamfering pegs and taking a hint off of the ends of parts that don't quite match. I turn to three different sanders: a 5" random-orbit, a 12" Sander trio smoothes and shapes in short order Sanding doesn't have to be an all-day affair if you outfit your shop with the right machine's. Your workhorse for finishing prep wilt probably be a random-orbit with hook-and-loop pads (left). The author recommends a benchtop spindle sander (middle) for cleaning up inside curves. A disc sander (right) is perfect for touching up miter angles, rounding over corners and evening up same-length parts when the need arises. 14 POWER TOOLS THAT WILL GROW WITH YOU Subscribe now at www.wpodworkersjournal.com/digitaledition |