Woodworker's Journal fall-2009, страница 74

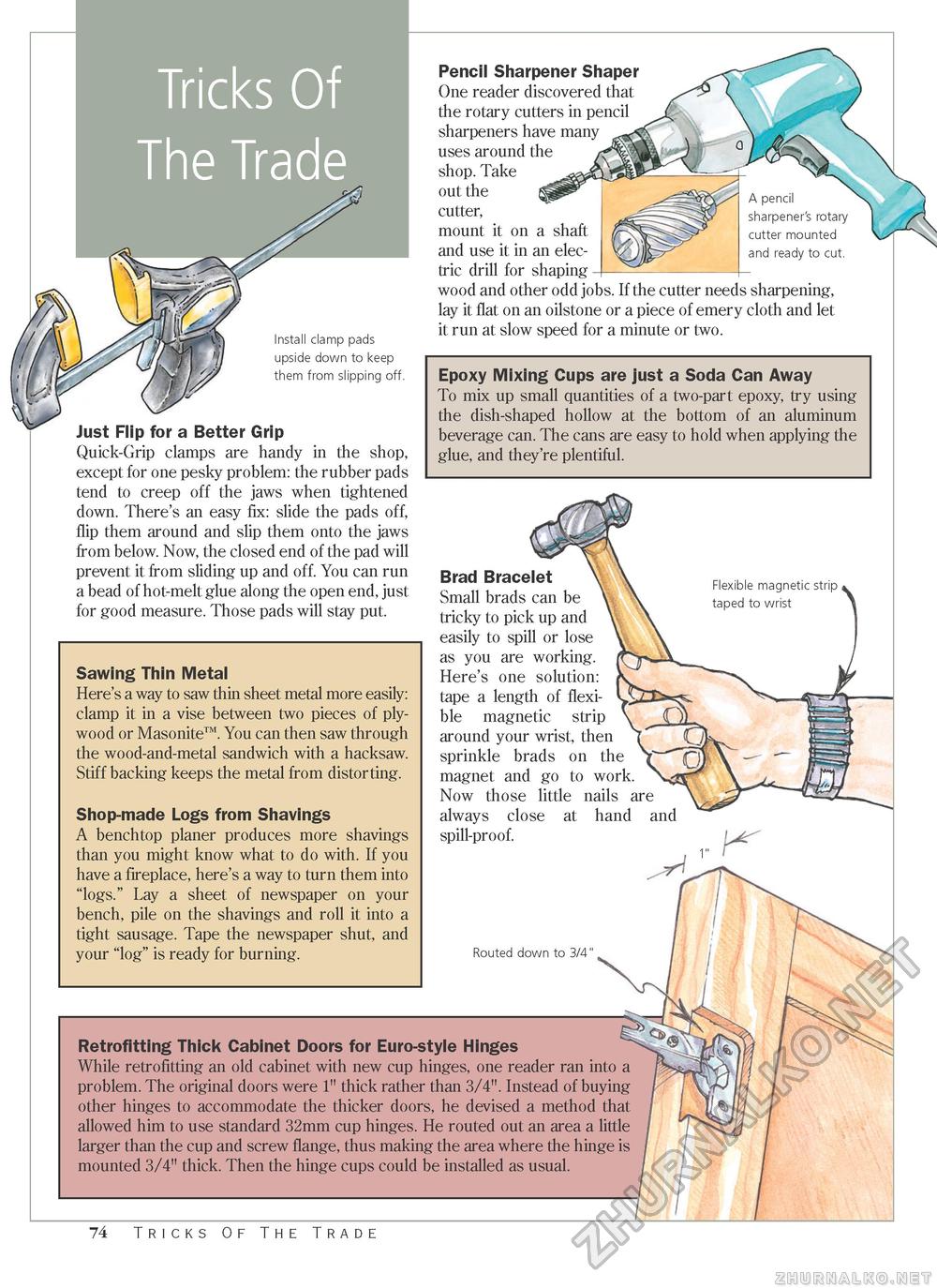

Tricks Of The Trade Install clamp pads upside down to keep them from slipping off. Just Flip for a Better Grip Quick-Grip clamps are handy in the shop, except for one pesky problem: the rubber pads tend to creep off the jaws when tightened down. There's an easy fix: slide the pads off, flip them around and slip them onto the jaws from below. Now, the closed end of the pad will prevent it from sliding up and off. You can run a bead of hot-melt glue along the open end, just for good measure. Those pads will stay put. Sawing Thin Metal Here's a way to saw thin sheet metal more easily: clamp it in a vise between two pieces of plywood or Masonite™. You can then saw through the wood-and-metal sandwich with a hacksaw. Stiff backing keeps the metal from distorting. Shop-made Logs from Shavings A benchtop planer produces more shavings than you might know what to do with. If you have a fireplace, here's a way to turn them into "logs." Lay a sheet of newspaper on your bench, pile on the shavings and roll it into a tight sausage. Tape the newspaper shut, and your "log" is ready for burning. Pencil Sharpener Shaper One reader discovered that the rotary cutters in pencil sharpeners have many uses around the shop. Take out the cutter, mount it on a shaft and use it in an electric drill for shaping wood and other odd jobs. If the cutter needs sharpening, lay it flat on an oilstone or a piece of emery cloth and let it run at slow speed for a minute or two. Epoxy Mixing Cups are just a Soda Can Away To mix up small quantities of a two-part epoxy, try using the dish-shaped hollow at the bottom of an aluminum beverage can. The cans are easy to hold when applying the glue, and they're plentiful. Brad Bracelet Small brads can be tricky to pick up and easily to spill or lose as you are working. Here's one solution: tape a length of flexible magnetic strip around your wrist, then sprinkle brads on the magnet and go to work. Now those little nails are always close at hand and spill-proof. Routed down to 3/4" Retrofitting Thick Cabinet Doors for Euro-style Hinges While retrofitting an old cabinet with new cup hinges, one reader ran into a problem. The original doors were 1" thick rather than 3/4". Instead of buying other hinges to accommodate the thicker doors, he devised a method that allowed him to use standard 32mm cup hinges. He routed out an area a little larger than the cup and screw flange, thus making the area where the hinge is mounted 3/4" thick. Then the hinge cups could be installed as usual. 74 Tricks Of The Trade |