Woodworker's Journal Summer-2008, страница 37

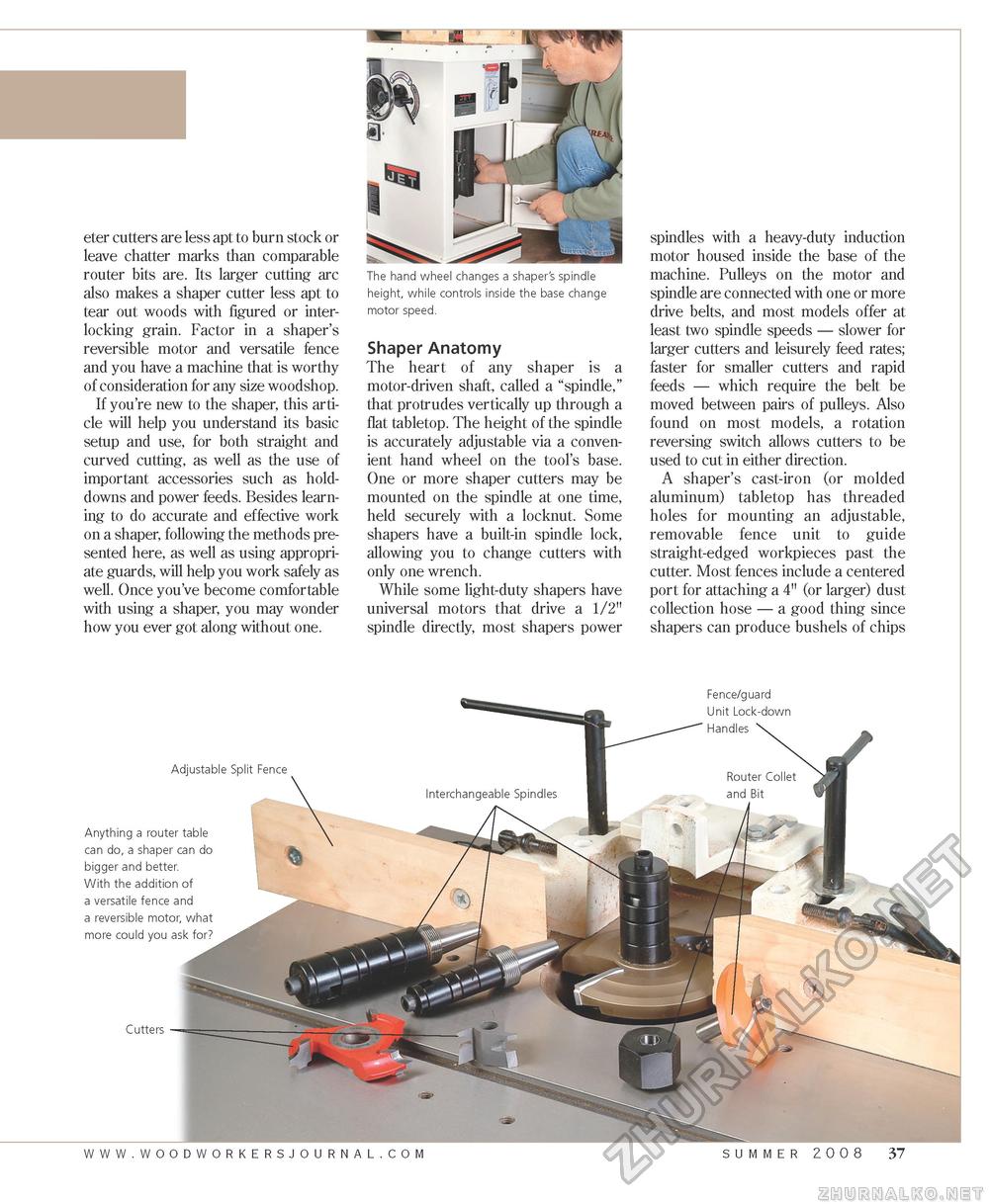

eter cutters are less apt to burn stock or leave chatter marks than comparable router bits are. Its larger cutting arc also makes a shaper cutter less apt to tear out woods with figured or interlocking grain. Factor in a shaper's reversible motor and versatile fence and you have a machine that is worthy of consideration for any size woodshop. If you're new to the shaper, this article will help you understand its basic setup and use, for both straight and curved cutting, as well as the use of important accessories such as hold-downs and power feeds. Besides learning to do accurate and effective work on a shaper, following the methods presented here, as well as using appropriate guards, will help you work safely as well. Once you've become comfortable with using a shaper, you may wonder how you ever got along without one. The hand wheel changes a shaper's spindle height, while controls inside the base change motor speed. Shaper Anatomy The heart of any shaper is a motor-driven shaft, called a "spindle," that protrudes vertically up through a flat tabletop. The height of the spindle is accurately adjustable via a convenient hand wheel on the tool's base. One or more shaper cutters may be mounted on the spindle at one time, held securely with a locknut. Some shapers have a built-in spindle lock, allowing you to change cutters with only one wrench. While some light-duty shapers have universal motors that drive a 1/2" spindle directly, most shapers power spindles with a heavy-duty induction motor housed inside the base of the machine. Pulleys on the motor and spindle are connected with one or more drive belts, and most models offer at least two spindle speeds — slower for larger cutters and leisurely feed rates; faster for smaller cutters and rapid feeds — which require the belt be moved between pairs of pulleys. Also found on most models, a rotation reversing switch allows cutters to be used to cut in either direction. A shaper's cast-iron (or molded aluminum) tabletop has threaded holes for mounting an adjustable, removable fence unit to guide straight-edged workpieces past the cutter. Most fences include a centered port for attaching a 4" (or larger) dust collection hose — a good thing since shapers can produce bushels of chips Fence/guard Unit Lock-down Handles Adjustable Split Fence Anything a router table can do, a shaper can do bigger and better. With the addition of a versatile fence and a reversible motor, what more could you ask for? Cutters www.woodworkersjourna l . c o m summer 2008 37 |