Creative Woodworks & crafts 1997-08, страница 53

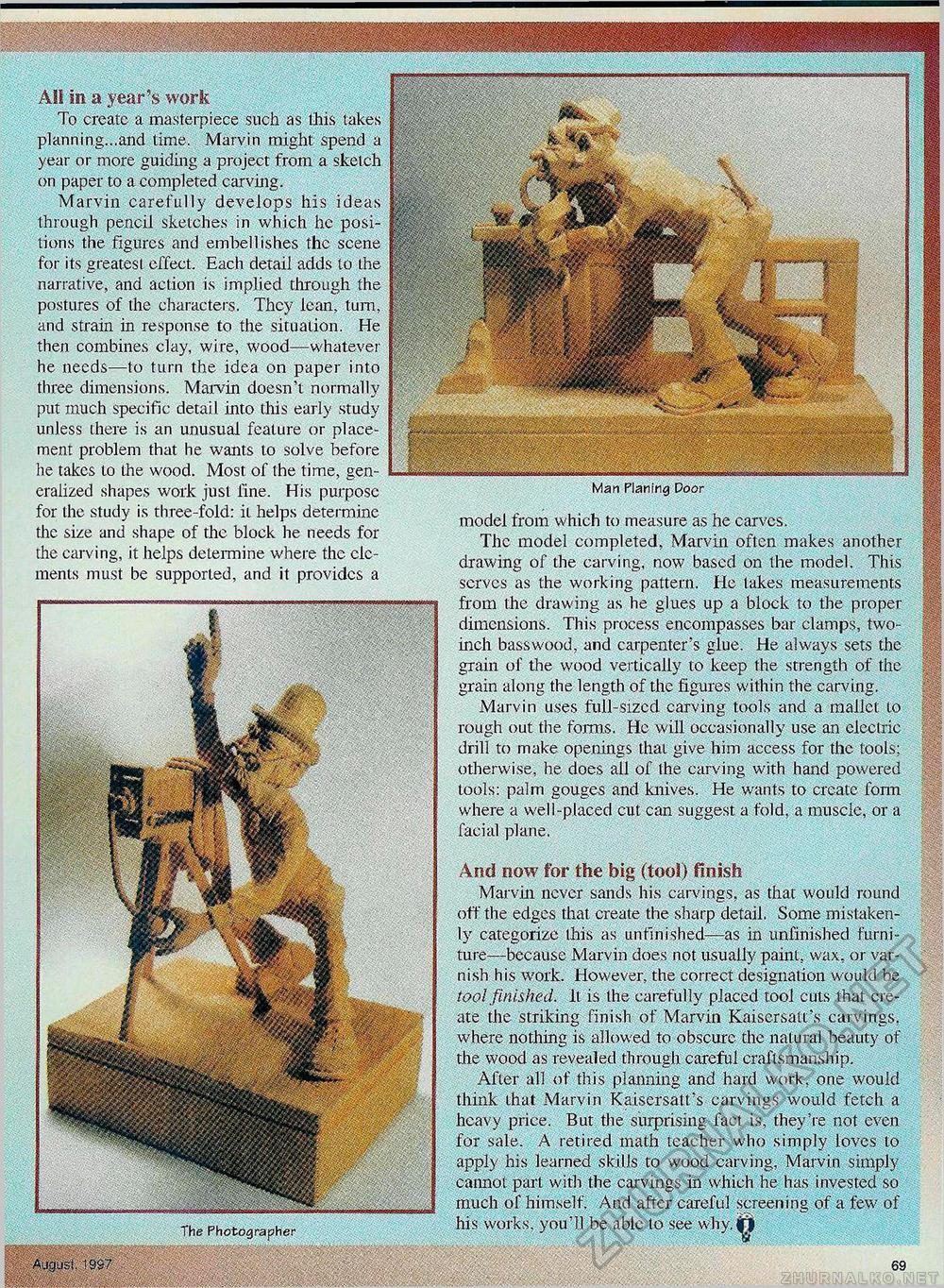

Man Planfng Door And now for the big (tool) finish Marvin never sands his carvings, as that would round off the edges that create the sharp detail. Some mistakenly categorize this as unfinished—as in unfinished furniture—because Marvin does not usually paint, wax, or varnish his work. However, the correct designation would be tool finished. It is the carefully placed tool cuts that create the striking finish of Marvin Kaisersatt's carvings, where nothing is allowed to obscure the natural beauty of the wood as revealed through careful craftsmanship. After all of this planning and hard work, one would think that Marvin Kaisersatt's carvings would fetch a heavy price. But the surprising fact is, they're not even for sale. A retired math teacher who simply loves to apply his learned skills to wood carving, Marvin simply cannot part with the carvings in which he has invested so much of himself, And after careful screening of a few of his works, you'll be able lo see why. The Photographer All in a year's work 1 To create a masterpiece such as this takes | planning...and time. Marvin might spend a 1 year or more guiding a project from a sketch I on paper to a completed carving. Marvin carefully develops his ideas | through pencil sketches in which he posi- | tions the figures and embellishes the scene If for its greatest effect. Each detail adds to the § narrative, and action is implied through the g postures of the characters. They lean, turn, | and strain in response to the situation. He | then combines clay, wire, wood—whatever | he needs—to turn the idea on paper into ff three dimensions. Marvin doesn't normally put much specific detail into this early study unless there is an unusual feature or placement problem that he wants to solve before he takes to the wood. Most, of the time, gen- L eralized shapes work just fine. His purpose for the study is three-fold: it helps determine the size and shape of the block he needs for the carving, it helps determine where the elements must be supported, and it provides a model from which to measure as he carves. The model completed, Marvin often makes another drawing of the carving, now based on the model. This serves as the working pattern. He takes measurements from the drawing as he glues up a block to the proper dimensions. This process encompasses bar clamps, two-inch bass wood, and carpenter's glue. He always sets the grain of the wood vertically to keep the strength of the grain along the length of the figures within the carving. Marvin uses full-sized carving tools and a mallet to rough out the forms. He will occasionally use an electric drill to make openings that give him access for the tools; otherwise, he does all of the carving with hand powered tools: palm gouges and knives. He wants to create form where a well-placed cut can suggest a fold, a muscle, or a facial plane. |