Creative Woodworks & crafts 1998-09, страница 28

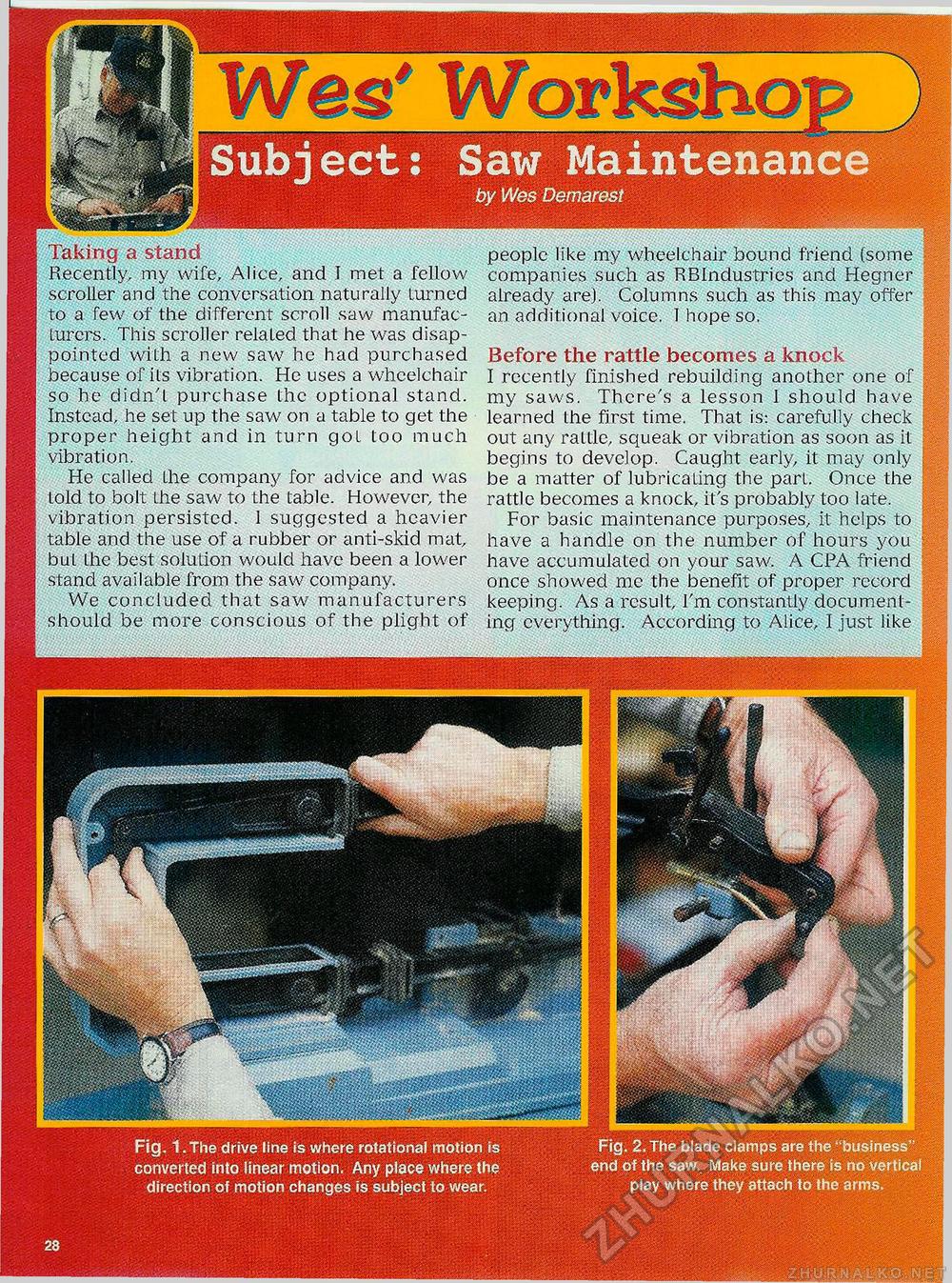

Was' Workshop Subject: Saw Maintenance by Wes Demarest Taking a stand Recently, my wife, Alice, and I met a fellow scroller and the conversation naturally turned to a few of the different scroll saw manufacturers. This scroller related that he was disappointed with a new saw he had purchased because of its vibration. He uses a wheelchair so he didn't purchase the optional stand. Instead, he set up the saw-7 on a table to get the proper height and in turn got too much vibration. He called the company for advice and was told to bolt Lhe saw to the table. However, the vibration persisted. 1 suggested a heavier table and the use of a rubber or anti-skid mat, but Lhe best solution would have been a lower stand available from the saw company. We concluded that saw manufacturers should be more conscious of the plight of people like my wheelchair bound friend (some companies such as RBIndustries and Hegner already are). Columns such as this may offer an additional voice. 1 hope so. Before the rattle becomes a knock I recently finished rebuilding another one of my saws. There's a lesson 1 should have learned the first time. That is: carefully check out any rattle, squeak or vibration as soon as it begins to develop. Caught early, it may only be a matter of lubricating the part. Once the rattle becomes a knock, it's probably too late. For basic maintenance purposes, it helps to have a handle on the number of hours you have accumulated on your saw. A CPA friend once showed me the benefit of proper record keeping. As a result, I'm constantly documenting everything. According to Alice, I just like Ili§ M§ sH m pst IIS 1 Fig. 1. The drive line is where rotational motion is converted into linear motion. Any place where the direction of motion changes is subject to wear. Fig. 2. The blade clamps are the "business" end of the saw. Make sure there is no vertical play where they attach to the arms. 28 |