Creative Woodworks & crafts 1998-09, страница 31

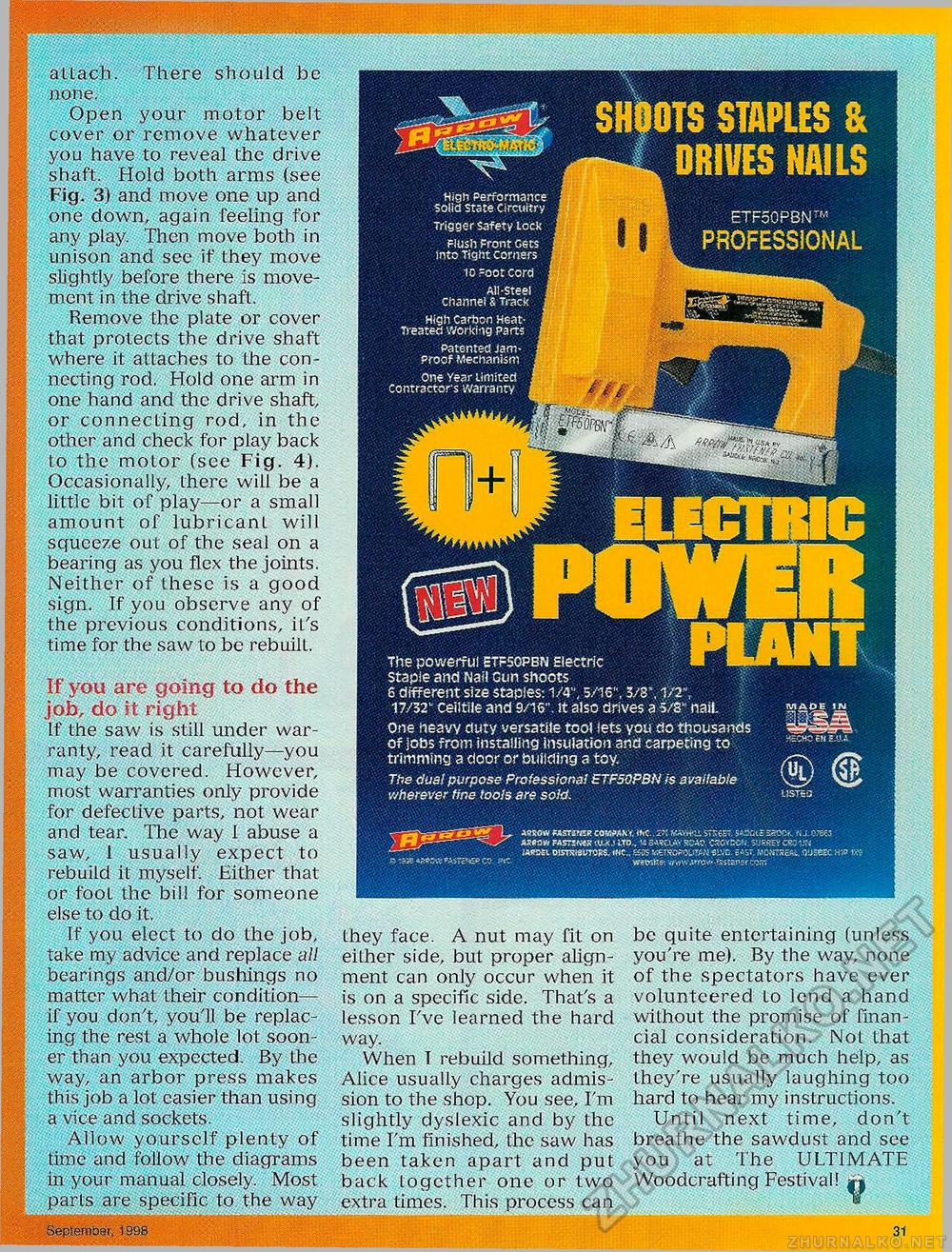

High Performance Solid State Circuitry Trigger Safety Lock Flush Front Gets into Tight corners ETF50PBN™ PROFESSIONAL PLANT The powerful stfsopbn Electric Staple and Nail Gun shoots 6 different size staples: 1/4", 5/16", 3/8', 1/2 17/32" ceiltile and 9/16". it also drives a 5/8" naiL One heavy duty versatile tool lets you do thousands of Jobs from installing insulation and carpeting to trimming a door or building a toy. The duel purpose Professional ETF50PBN is available vjherever tine tools are sold. ASSO* MSTSN5R COMPAN Y. «lC..iS WBWSi STSSST: $aS£it= S80S8. «J.Wt» txtom mstimr «uu ltd.. '4 s«cwiv sew. cswfecfi: sussar cc; v'i iATOSl DiS7S(Sirroi!S. IHC.. SOS IiKTSpPOUTAN -Si-VD. E^ST, MOKTScAi.. QUSBEC HIS 1K' attach. There should be none. Open your motor belt cover or remove whatever you have to reveal the drive shaft. Hold both arms (see Fig. 3) and move one up and one down, again feeling for any play. Then move both in unison and see if they move slightly before there is movement in the drive shaft. Remove the plate or cover that protects the drive shaft where it attaches to the connecting rod. Hold one arm in one hand and the drive shaft, or connecting rod, in the other and check for play back to the motor (see Fig. 4). Occasionally, there will be a little bit of play—or a small amount of lubricant will squeeze out of the seal on a bearing as you flex the joints. Neither of these is a good sign. If you observe any of the previous conditions, it's time for the saw to be rebuilt. If you are going to do the IttMMMKi^ job, do it right ^■SS^gyBffi^B^SB If the saw is still under war-ranty, read it carefully—you may be covered. However, ^BK^KuKKSmI^^^^^sM most warranties only provide for defective parts, not wear and tear. The way I abuse a saw, 1 usually expect to S^^^^^pllp^^^^^g^K^^aBia^^^j^S rebuild it myself. Either that or foot the bill for someone else to do it. If you elect to do the job, ihey face. A nut may fit on take my advice and replace all either side, but proper align- bearings and/or bushings no ment can only occur when it matter what their condition— is on a specific side. That's a if you don't, you'll be replac- lesson I've learned the hard ing the rest a whole lot soon- way. er than you expected. By the When T rebuild something, way, an arbor press makes Alice usually charges admis- this job a lot easier than using sion to the shop. You see, I'm a vice and sockets. slightly dyslexic and by the Allow yourself plenty of time I'm finished, the saw has time and follow the diagrams been taken apart and put in your manual closely. Most back together one or two parts are specific to the way extra times. This process can be quite entertaining (unless you're me). By the way, none of the spectators have ever volunteered to lend a hand without the promise of financial consideration. Not that they would be much help, as they're usually laughing too hard to hear my instructions. Until next time, don't breathe the sawdust and see you at The ULTIMATE Woodcrafting Festival! Septefnbar, 1998 |