Creative Woodworks & crafts 2001-04, страница 52

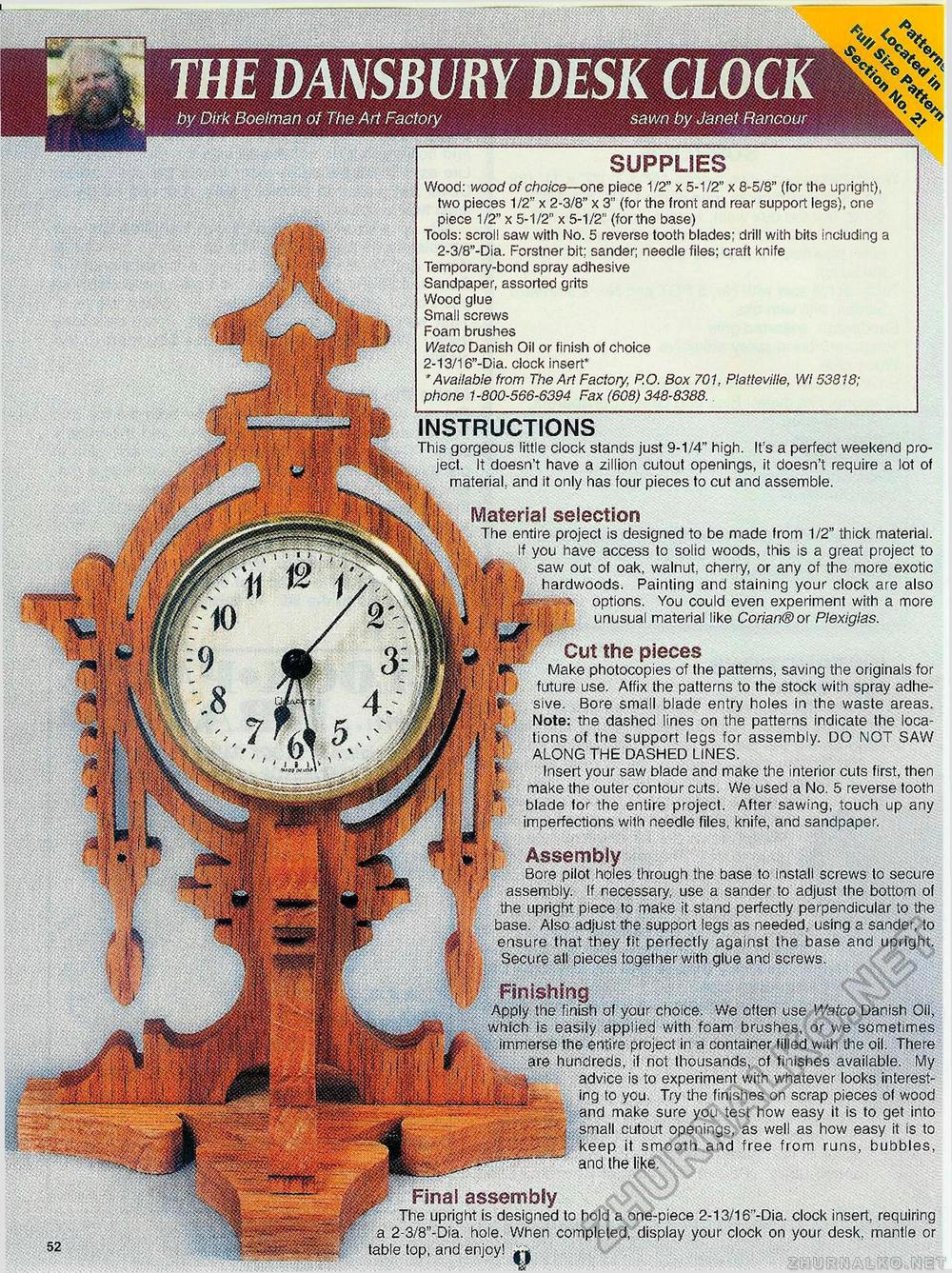

by Dirk Boeiman of The Art Factory sawn by Janet Rancour mm Wood: wood of choice—one piece 1/2" x 5-1/2" x 8-5/8" (for the upright), two pieces 1/2" x 2-3/8" x 3" (for the front and rear support legs), one piece 1/2" x 5-1/2" x 5-1/2" (for the base) Tools: scroll saw with No. 5 reverse tooth blades; drill with bits including a 2-3/8"-Dia. Forstner bit; sander; needle files; craft knife Temporary-bond spray adhesive Sandpaper, assorted grits Wood glue Small screws Foam brushes Watco Danish Oil or finish of choice 2-13/16"-Dia. clock insert* * Available from The Art Factory, P.O. Box 701, Platteville, Wl 53818; phone 1-800-566-6394 Fax (608) 348-8388. INSTRUCTIONS This gorgeous little clock stands just 9-1/4" high. It's a perfect weekend project. It doesn't have a zillion cutout openings, it doesn't require a lot of material, and it only has four pieces to cut and assemble. Material selection ..^l The entire project is designed to be made from 1/2" thick material. If you have access to solid woods, this is a great project to '"'"'' saw out of oak. walnut, cherry, or any of the more exotic hardwoods. Painting and staining your clock are also , options. You could even experiment with a more fifel unusual material like Corian® or Plexiglas. Cut the pieces Make photocopies of the patterns, saving the originals for future use. Affix the patterns to the stock with spray adhesive. Bore small blade entry holes in the waste areas. Note: the dashed lines on the patterns indicate the locations of the support legs for assembly. DO NOT SAW ALONG THE DASHED LINES. Insert your saw blade and make the interior cuts first, then make the outer contour cuts. We used a No. 5 reverse tooth blade for the entire project. After sawing, touch up any imperfections with needle files, knife, and sandpaper. Assembly Bore pilot holes through the base to install screws to secure assembly. If necessary, use a sander to adjust the bottom of the upright piece to maike it stand perfectly perpendicular to the base. Also adjust the support legs as needed, using a sander, to ensure that they fit perfectly against the base and upright. Secure all pieces together with glue and screws. Finishing Apply the finish of your choice. We often use Watco Danish Oil, which is easily applied with foam brushes, or we sometimes ■ immerse the entire project in a container filled with the oil. There : are hundreds, if not thousands, of finishes available. My advice is to experiment with whatever looks interesting to you. Try the finishes on scrap pieces of wood and make sure you test how easy it is to get into small cutout openings, as well as how easy it is to keep it smooth and free from runs, bubbles, and the like. Final assembly The upright is designed to hold a one-piece 2-13/16"-Dia. clock insert, requiring a 2-3/8"-Dia. hole. When completed, display your clock on your desk, mantle or table top, and enjoy! |-j supplies |