Creative Woodworks & crafts 2001-08, страница 32

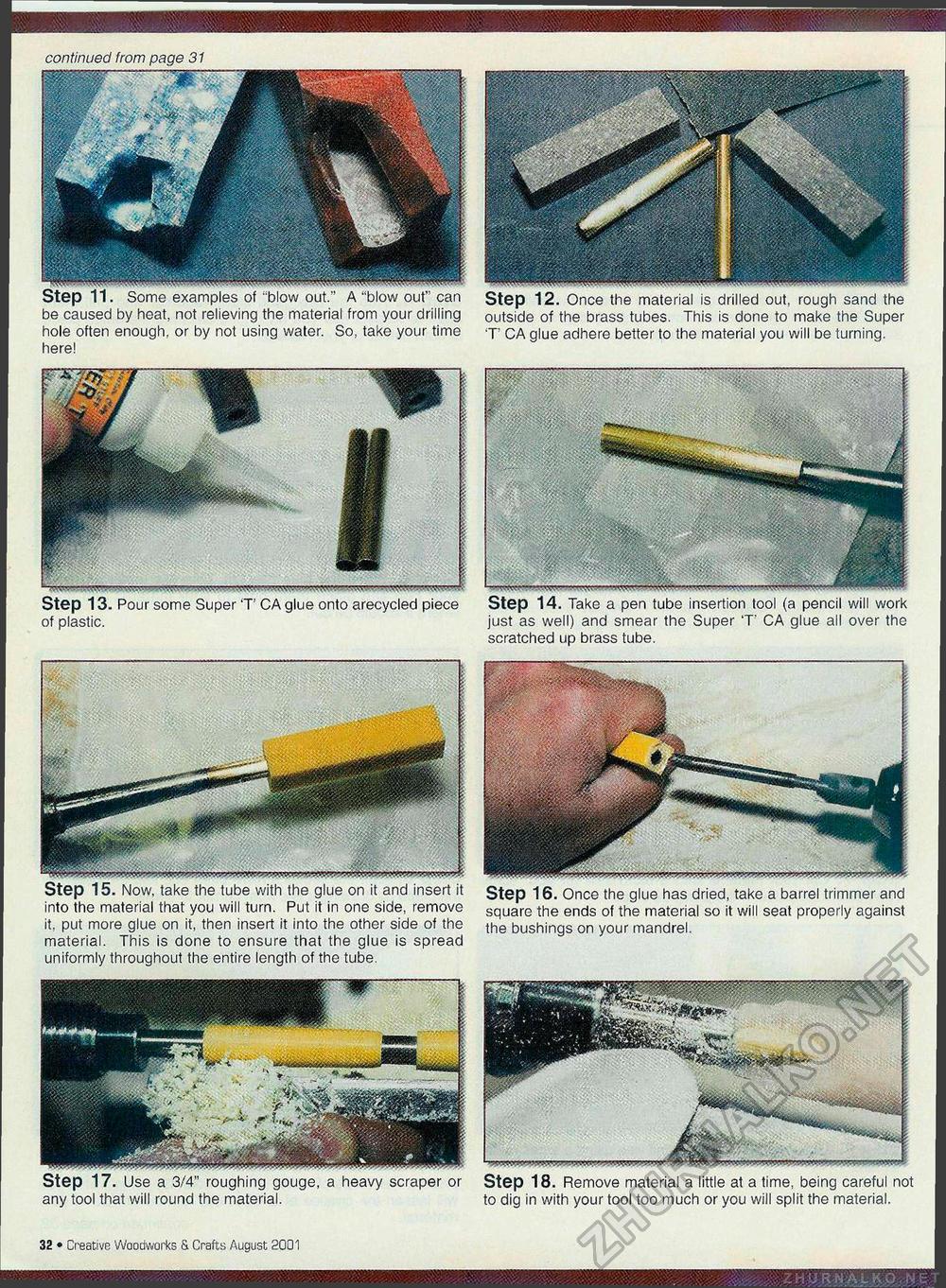

continued from page 31 ___^ ... Some examples of "blow out." A "blow out" can be caused by heat, not relieving the material from your drilling hole often enough, or by not using water. So, take your time here! Step 12. Once the material is drilled out, rough sand the outside of the brass tubes. This is done to make the Super T CA glue adhere better to the material you will be turning. Step 13. Pour some Super T CAglue onto arecycled piece of plastic. 14. Take a pen tube insertion tool (a pencil will work just as well) and smear tho Super T CA glue all over the scratched up brass tube. ____ . Now, take the tube with the glue on it and insert it into the material that you will turn. Put it in one side, remove it, put more glue on it, then insert it into the other side of the material. This is done to ensure that the glue is spread uniformly throughout the entire length of the tube. Step 16. Once the glue has dried, take a barrel trimmer and square the ends of the material so it will seat properly against the bushings on your mandrel. Step 18. Remove material a little at a time, being careful not to dig in with your tool too much or you will split the material. . Use a 3/4" roughing gouge, a heavy scraper or any tool that will round the material. 32 • Creative Woodworks S. Crafts August 2001 |