Creative Woodworks & crafts 2002-03, страница 52

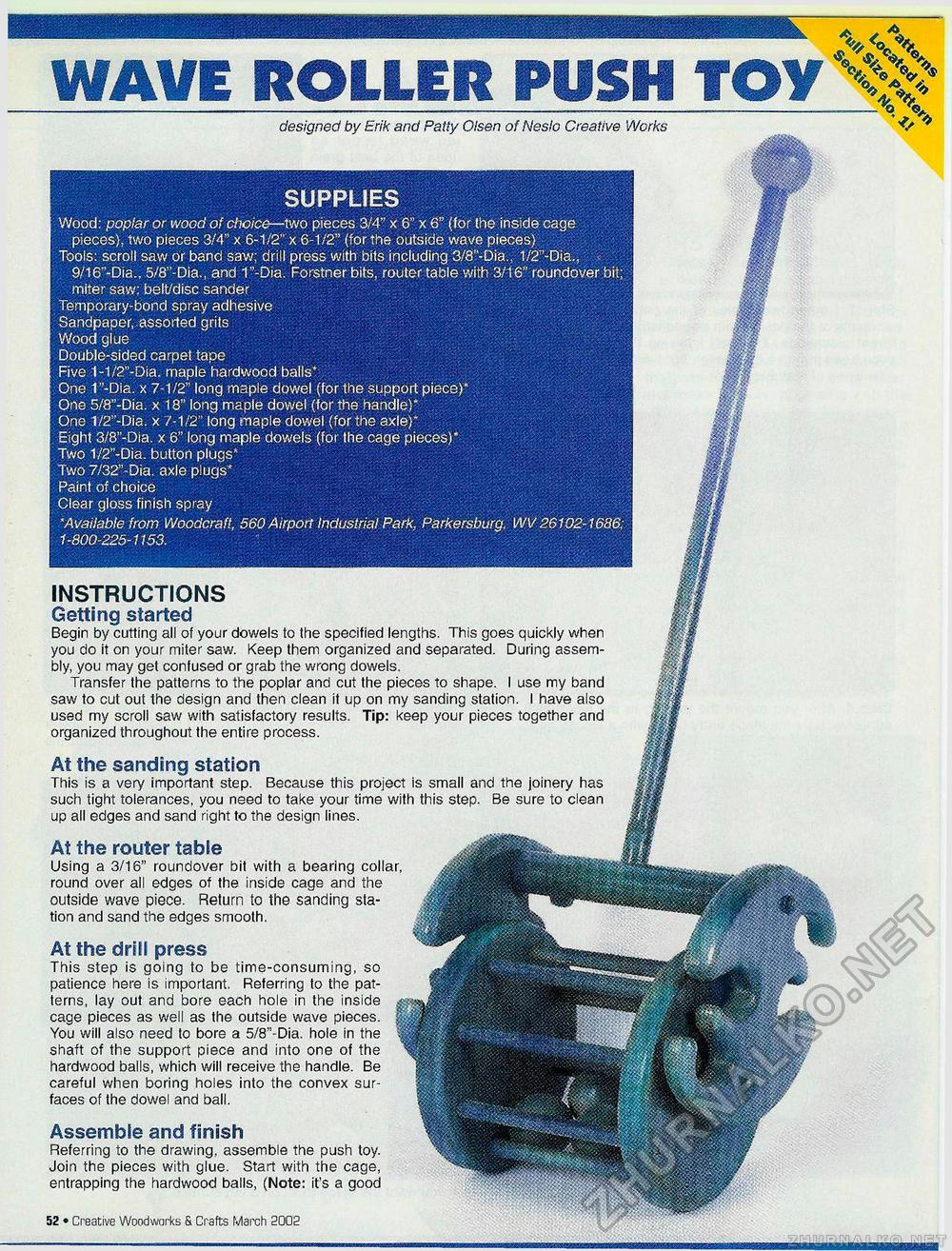

SUPPLIES Wood: poplar or wood of choice—two pieces 3/4" x 6" x 6" (for the inside cage pieces), two pieces 3/4" x 6-1/2" x 6-1/2" (for the outside wave pieces) Tools: scroll saw or band saw; drill press with bits including '3/8'-.Dia., 1/2:'-Dia,, 9/16"-Dia., 5/8"-Dia., and T'-Dia. Forstner bits, router table with 3/16" roundover bit; miter saw; belt/disc sander Temporary-bond spray adhesive Sandpaper, assorted grits Wood glue Double-sided carpet tape Five 1-1 /2"-Dia. maple hardwood balls* One 1"-Dia. x 7-1/2" long maple dowel (for the support piece)* One 5/8"-Dia. x 18" long maple dowel (tor the handle)* One 1/2"-Dia. x 7-1/2" long maple dowel (for the axle)* Eight 3/8"-Dia. x 6" long maple dowels (for the cage pieces)* Two 1/2"-Dia. button plugs* Two 7/32"-Dia. axle plugs* Paint of choice Clear gloss finish spray "Available from Woodcraft, 560 Airport Industrial Park. Parkersburg, WV 26102-1686; 1-800-225-1153. WAVE ROLLER PUSH TOY designed by Erik and Patty Olsen of Neslo Creative Works Assemble and finish Referring to the drawing, assemble the push toy. Join the pieces with glue. Start with the cage, entrapping the hardwood balls, (Note: it's a good 52 • Creative Woodworks & Crafts March 2003 INSTRUCTIONS Getting started Begin by cutting all of your dowels to the specified lengths. This goes quickly when you do it on your miter saw. Keep them organized and separated. During assembly, you may get confused or grab the wrong dowels. Transfer the patterns to the poplar and cut the pieces to shape. I use my band saw to cut out the design and then clean it up on my sanding station. I have also used my scroll saw with satisfactory results. Tip: keep your pieces together and organized throughout the entire process. At the sanding station This is a very important step. Because this project is small and the joinery has such tight tolerances, you need to take your time with this step. Be sure to clean up all edges and sand right to the design lines. At the router table Using a 3/16" roundover bit with a bearing collar, round over all edges of the inside cage and the outside wave piece. Return to the sanding station and sand the edges smooth. At the drill press This step is going to be time-consuming, so patience here is important. Referring to the patterns, lay out and bore each hole in the inside cage pieces as well as the outside wave pieces. You will also need to bore a 5/8"-Dia. hole in the shaft of the support piece and into one of the hardwood balls, which will receive the handle. Be careful when boring holes into the convex surfaces of the dowel and ball. |