Creative Woodworks & crafts 2004-09, страница 27

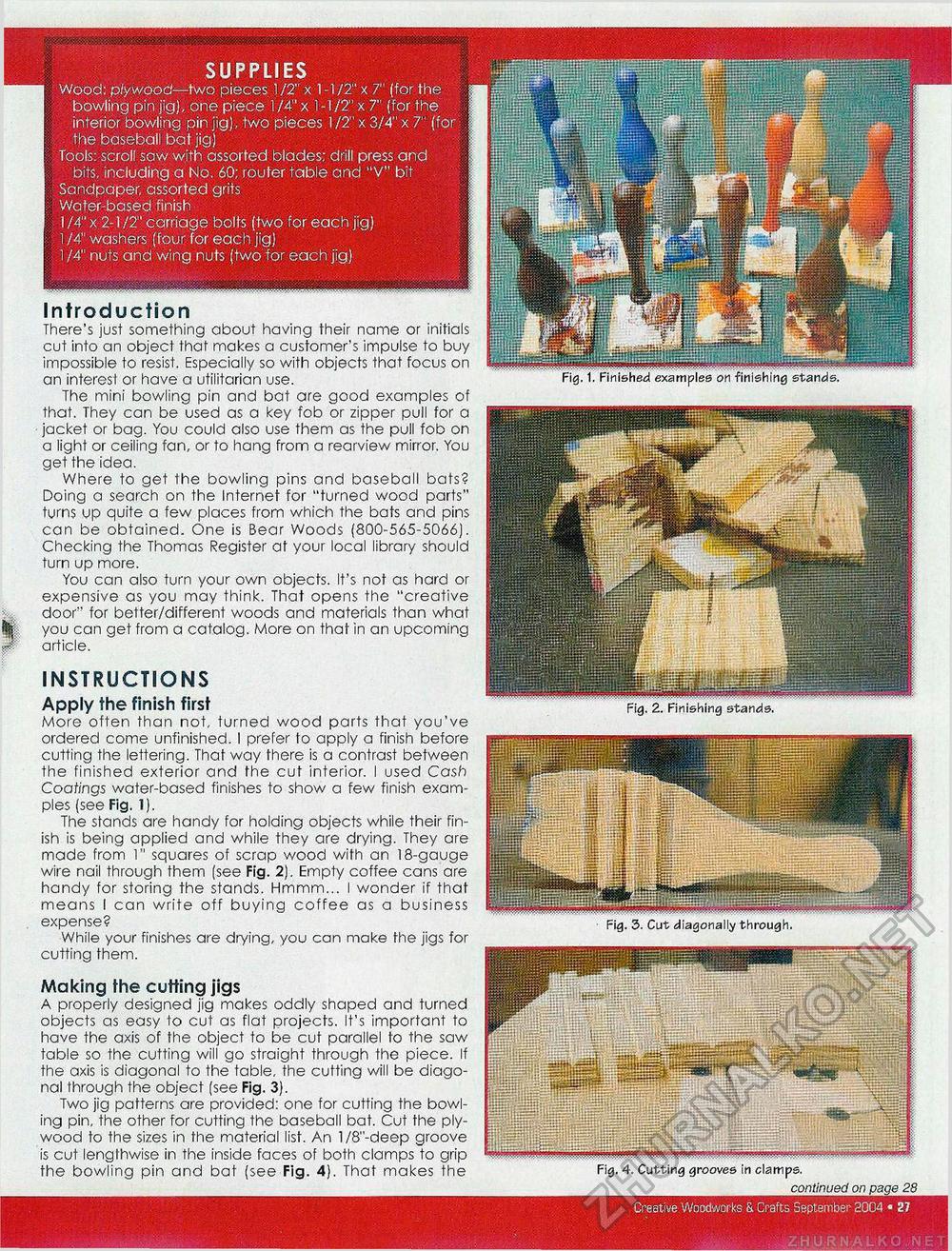

Fig. 1. Finished examples on finishing stands. 1(1 • Creative Woodworks & Crafts September 3004 SUPPLIES Wood: plywood—two pieces I /2" x 1 -1 /2" x 7" (for the bowling pin jig), one piece 1/4" x 1-1/2" x 7" (for the interior bowling pin jig), two pieces 1/2" x 3/4' x 7" (for the baseball bat jig) Tools: scroll saw with assorted blades; drill press and bits, including a No. 60; router table and "V" bit Sandpaper, assorted grits Water-based finish 1 /4" x 2-1/2" carriage bolts (two for each jig) 1 /4" washers (four for each jig) 1 /4" nuts and wing nuts (two for each jig) Introduction There's just something about having their name or initials cut into an object that makes a customer's impulse to buy impossible to resist. Especially so with objects that focus on an interest or have a utilitarian use. The mini bowling pin and bat are good examples of that. They can be used as a key fob or zipper pull for a jacket or bag. You could also use them as the pull fob on a light or ceiling fan, or to hang from a rearview mirror. You get the idea. Where to get the bowling pins and baseball bats? Doing a search on the Internet for "turned wood parts" turns up quite a few places from which the bats and pins can be obtained. One is Bear Woods (800-565-5066). Checking the Thomas Register at your local library should turn up more. You can also turn your own objects. It's not as hard or expensive as you may think. That opens the "creative door" for better/different woods and materials than what you can get from a catalog. More on that in an upcoming article. INSTRUCTIONS Apply the finish first More often than not, turned wood parts that you've ordered come unfinished. I prefer to apply a finish before cutting the lettering. That way there is a contrast between the finished exterior and the cut interior. I used Cash Coatings water-based finishes to show a few finish examples (see Fig. 1). The stands are handy for holding objects while their finish is being applied and while they are drying. They are made from 1" squares of scrap wood with an 18-gauge wire nail through them (see Fig. 2). Empty coffee cans are handy for storing the stands. Hmmm... I wonder if that means I can write off buying coffee as a business expense? While your finishes are drying, you can make the jigs for cutting them. Making the cutting jigs A properly designed jig makes oddly shaped and turned objects as easy to cut as flat projects. It's important to have the axis of the object to be cut parallel to the saw table so the cutting will go straight through the piece. If the axis is diagonal to the table, the cutting will be diagonal through the object (see Fig. 3). Two jig patterns are provided: one for cutting the bowling pin, the other for cutting the baseball bat. Cut the plywood to the sizes in the material list. An l/8"-deep groove is cut lengthwise in the inside faces of both clamps to grip the bowling pin and bat (see Fig. 4). That makes the Fig. 4. Cutting grooves in clamps. _continued on page 28 Fig. 3. Cut diagonally through. |