Creative Woodworks & crafts 2004-09, страница 28

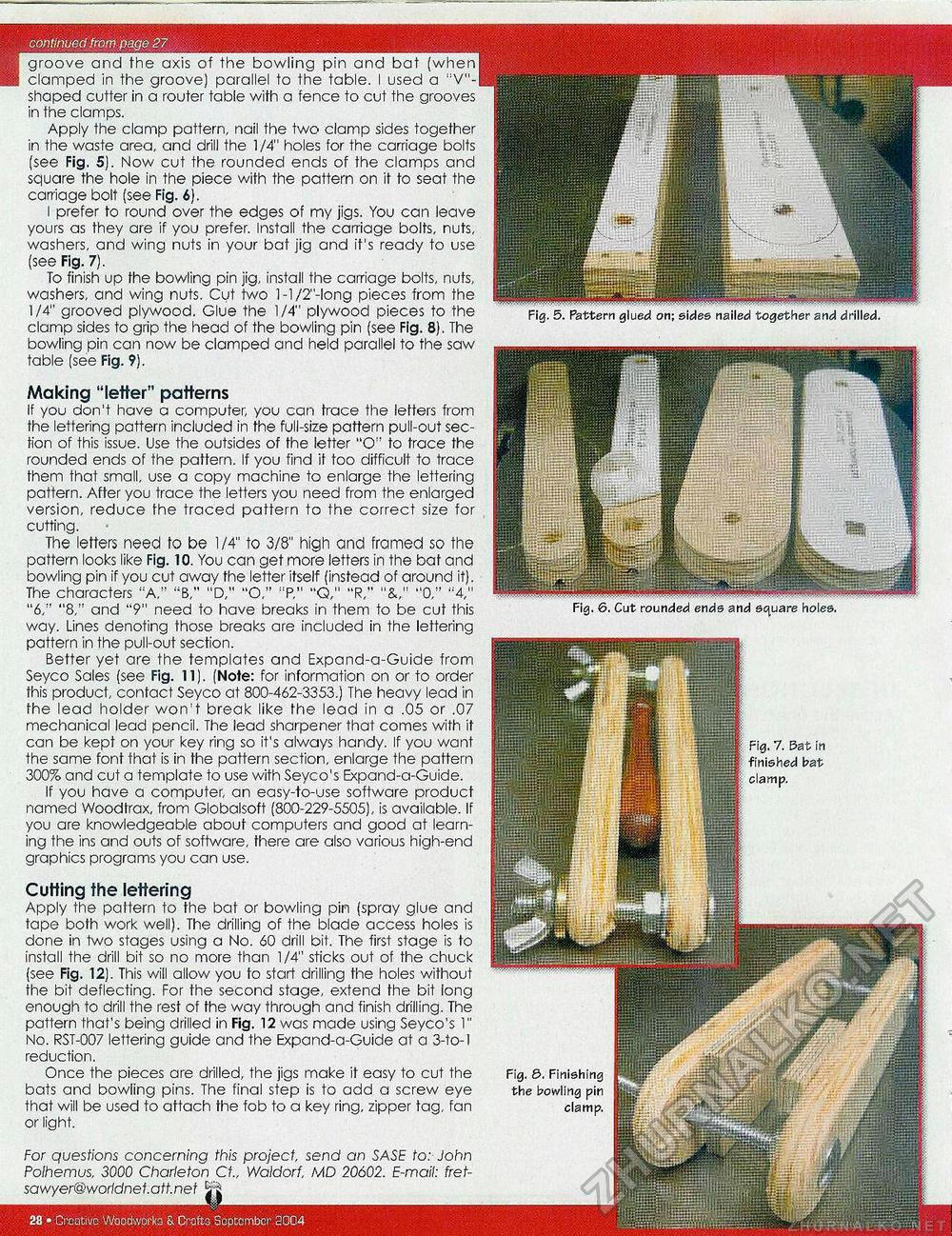

Making "letter" patterns If you don't have a computer, you can trace the letters from the lettering pattern included in the full-size pattern pull-out section of this issue. Use the outsides of the letter "O" to trace the rounded ends of the pattern. If you find it too difficult to trace them that small, use a copy machine to enlarge the lettering pattern. After you trace the letters you need from the enlarged version, reduce the traced pattern to the correct size for cutting. The letters need to be 1/4" to 3/8" high and framed so the pattern looks like Fig. 10. You can get more letters in the bat and bowling pin if you cut away the letter itself (instead of around it). The characters "A." "B," "D," "O," "P," "Q," "R," "&," "0," "A," "6," "8," and "9" need to have breaks in them to be cut this way. Lines denoting those breaks are included in the lettering pattern in the pull-out section. Better yet are the templates and Expand-a-Guide from Seyco Sales (see Fig. 11). (Note: for information on or to order this product, contact Seyco at 800-462-3353.) The heavy lead in the lead holder won't break like the lead in a .05 or .07 mechanical lead pencil. The lead sharpener that comes with it can be kept on your key ring so it's always handy. If you want the same font that is in the pattern section, enlarge the pattern 300% and cut a template to use with Seyco's Expand-a-Guide. If you have a computer, an easy-to-use software product named Woodtrax, from Globalsoft (800-229-5505), is available. If you are knowledgeable about computers and good at learning the ins and outs of software, there are also various high-end graphics programs you can use. Cutting the lettering Apply the pattern to the bat or bowling pin (spray glue and tape both work well). The drilling of the blade access holes is done in two stages using a No. 60 drill bit. The first stage is to install the drill bit so no more than 1/4" sticks out of the chuck (see Fig. 12). This will allow you to start drilling the holes without the bit deflecting. For the second stage, extend the bit long enough to drill the rest of the way through and finish drilling. The pattern that's being drilled in Fig. 12 was made using Seyco's 1" No. RST-007 lettering guide and the Expand-a-Guide at a 3-to-l reduction. Once the pieces are drilled, the jigs make it easy to cut the bats and bowling pins. The final step is to add a screw eye that will be used to attach the fob to a key ring, zipper tag, fan or light. Fig. &. Finishing the bowling pin clamp. For questions concerning this project, send an SASE to: John Polhemus, 3000 Charleton Cf„ Waldorf, MD 20602. E-mail: fret-sawyer@worldnet.att.net groove and the axis of the bowling pin and bat (when clamped in the groove) parallel to the table. I used a "V" shaped cutter in a router table with a fence to cut the grooves in the clamps. Apply the clamp pattern, nail the two clamp sides together in the waste area, and drill the 1/4" holes for the carriage bolts (see Fig. 5). Now cut the rounded ends of the clamps and square the hole in the piece with the pattern on it to seat the carriage bolt (see Fig. 6). I prefer to round over the edges of my jigs. You can leave yours as they are if you prefer. Install the carriage bolts, nuts, washers, and wing nuts in your bat jig and it's ready to use (see Fig. 7). To finish up the bowling pin jig, install the carriage bolts, nuts, washers, and wing nuts. Cut two l-l/2"-long pieces from the 1/4" grooved plywood. Glue the 1/4" plywood pieces to the clamp sides to grip the head of the bowling pin (see Fig. 8). The bowling pin can now be clamped and held parallel to the saw table (see Fig. 9). Fig. 5. Pattern glued on; sides nailed together and drilled. |