Creative Woodworks & crafts 2005-01, страница 48

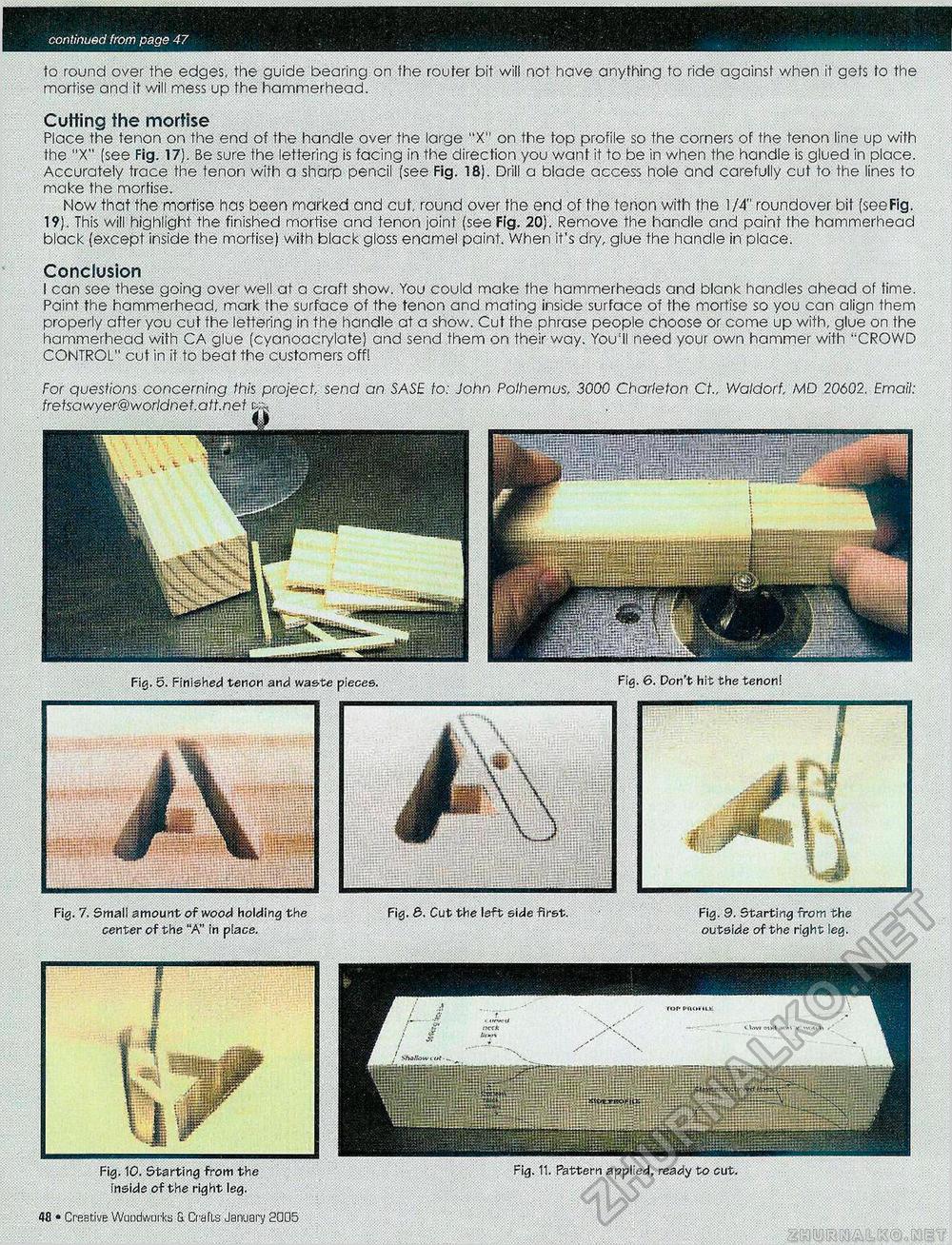

Sipsiifpip! mmM Fig. 7. Small amount of wood holding the center of the "A" in place. Shallow cot continued from page 47 to round over the edges, the guide bearing on the router bit will riot have anything to ride against when it gets to the mortise and it will mess up the hammerhead. Cutting the mortise Place the tenon on the end of the handle over the large "X" on the top profile so the corners of the tenon line up with the "X" (see Fig. 17). Be sure the lettering is facing in the direction you want it to be in when the handle is glued in place. Accurately trace the tenon with a sharp pencil (see Fig. 18). Drill a blade access hole and carefully cut to the lines to make the mortise. Now that the mortise has been marked and cut, round over the end of the tenon with the 1/4" roundover bit (seeFig. 19). This will highlight the finished mortise and tenon joint (see Fig. 20). Remove the handle and paint the hammerhead black (except inside the mortise) with black gloss enamel paint. When it's dry,, glue the handle in place. For questions concerning this project, send an SASE to: John Polhemus, 3000 Charleton CL Waldorf, MD 20602, Email: fretsawyer@worldnet.att.nef c»% , Fig. 10. Starting from the inside of the right leg. Fig. 11. Pattern applied, ready to cut. Conclusion I can see these going over well at a craft show. You could make the hammerheads and blank handles ahead of time. Paint the hammerhead, mark the surface of the tenon and mating inside surface of the mortise so you can align them properly after you cut the lettering in the handle at a show. Cut the phrase people choose or come up with, glue on the hammerhead with CA glue (cyanoacrylate) and send them on their way. You'll need your own hammer with "CROWD CONTROL" cut in it to beat the customers off! Fig. 5. Finished tenon and waste pieces. Fig. 6. Don't hit the tenon! Fig. 9. Starting from the outside of the right leg. 48 • Creative Woodworks S. Crafts January 2005 |